Chapter 7 Maintenance and Inspection

29

Lubricant replacement

7.4.

Lubricant replacement time

7.4.1.

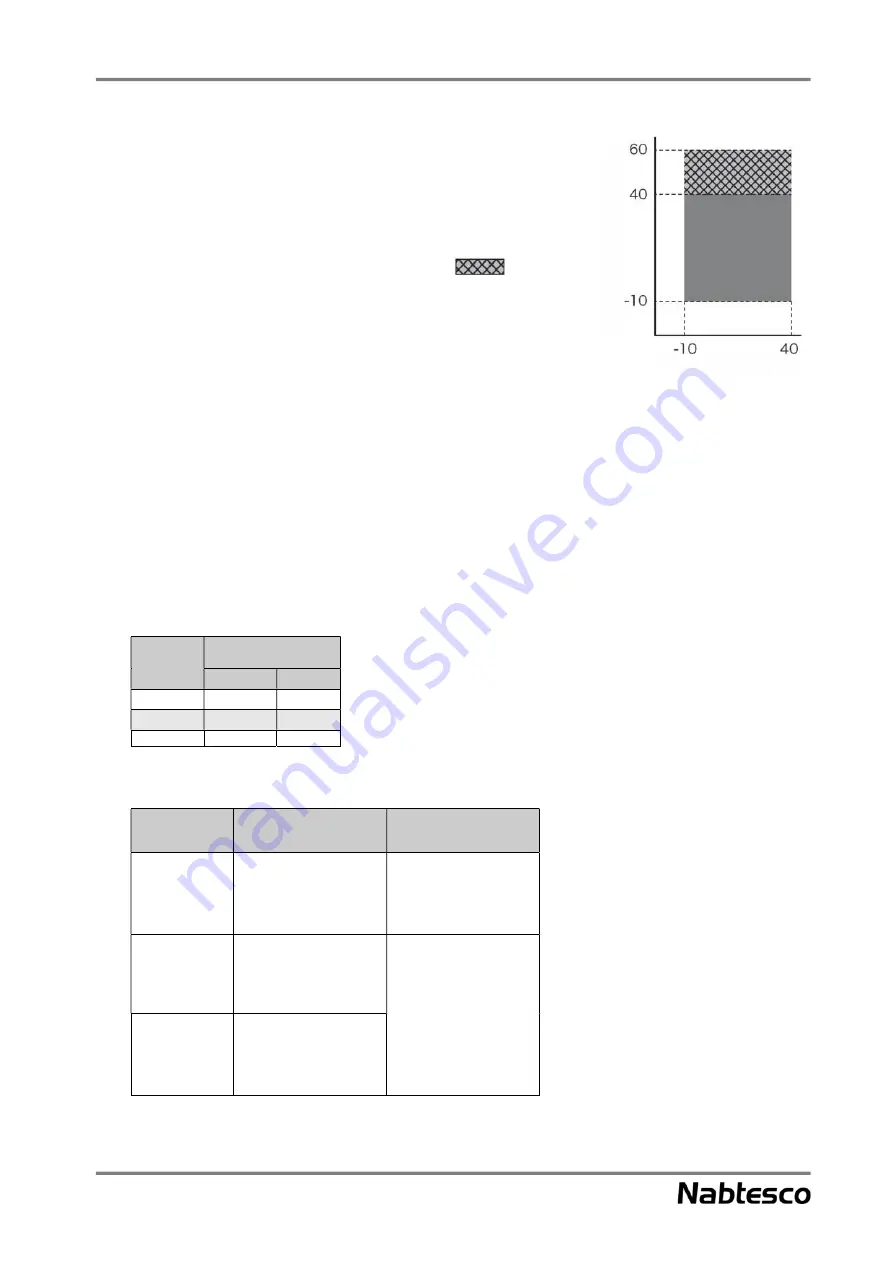

When this product is operated filled with an appropriate amount of

lubricant, the standard lubricant replacement time due to lubricant

degradation is 20,000 hours. However, when operation involves a

reduction gear surface temperature above 40°C (the

area in the

right diagram), the state of the lubricant should be checked in advance and

the grease replaced earlier as necessary. For the lubricants specified by

Nabtesco, refer to “2.2 Lubricant”.

Preparation

7.4.2.

• Lubricant

For the RS-260A, prepare as much VIGOGREASE RE0 as needed, and for the RS-320A and

RS-900A prepare as much Molywhite RE00 as needed, according to the number of units. (For the

amount of lubricant, refer to Table 7-2.)

• Seal tape

• Tightening tool

Prepare the tightening tool based on Table 7-3.

Amount of specified lubricant

Table 7-2

Model

Required amount

cc

(kg)

RS-260A

3,900

(3.5)

RS-320A

5,200

(4.5)

RS-900A

17,000

(14.8)

Plug size and tightening torque

Table 7-3

Frame number

Grease drainage side

Grease injection side

RS-260A

Hexagon socket head cap

plug

GM-1/4

Tightening torque

29.4 ± 4.9 (Nm)

Hexagon socket head cap

plug

GM-1/4

Tightening torque

29.4 ± 4.9 (Nm)

RS-320A

Hexagon socket flange

head screw plug

GFO-M10

Tightening torque

19.6 ± 0.98 (Nm)

Hexagon socket head cap

plug

GM-1/8

Tightening torque

12.3 ± 2.45 (Nm)

RS-900A

Hexagon socket head cap

plug

GM-1/8

Tightening torque

12.3 ± 2.45 (Nm)

Fig. 7-1

Ambient temperature (°C)

R

e

du

ct

io

n

g

ea

r

su

rf

ace

t

em

p

e

ra

tu

re

(

°C

)