24

TRACTOR AND MOWER

Every 8 Hours or Daily

Check safety interlock system

Clean debris o tractor and mower deck

Clean debris from engine compartment

Every 25 Hours or Annually *

Check tire pressure

Check mower blade stopping time

Check tractor and mower for loose hardware

Every 50 Hours or Annually *

Clean battery and cables

Check tractor brakes

See Dealer Annually to

Lubricate tractor and mower

Check mower blades **

ENGINE

First 5 Hours

Change engine oil

Every 8 Hours or Daily

Check engine oil level

Every 25 Hours or Annually *

Clean engine air lter and pre-cleaner **

Every 50 Hours or Annually *

Change engine oil

Replace oil lter

Annually

Replace air lter

Replace pre-cleaner

See Dealer Annually to

Inspect mu

er and spark arrester

Replace spark plug

Replace fuel lter

Clean engine air cooling system

* Whichever comes rst

** Check blades more often in regions with sandy soils or

high dust conditions.

* Whichever comes rst

** Clean more often in dusty conditions or when airborne

debris is present.

Maintenance Chart

Emissions Statement

Maintenance, replacement, or repair of the emissions control

devices and systems may be performed by any non-road

engine repair establishment or individual. However, to obtain

“no charge” emissions control service, the work must be per-

formed by a factory authorized dealer.

Maintenance

WARNING

Unintentional sparking can result in re or elec-

tric shock.

Unintentional start-up can result in entangle-

ment, traumatic amputation, or laceration.

Before performing adjustments or repairs:

• Disconnect the spark plug wire and keep it away

from the spark plug.

• Disconnect battery at negative terminal (only en-

gines with electric start).

• Use only correct tools.

• Do not tamper with governor spring, links, or other

parts to increase engine speed.

• Replacement parts must be of the same design and

installed in the same position as the original parts.

Other parts may not perform as well, may damage

the unit, and may result in injury.

• Do not strike the ywheel with a hammer or hard ob-

ject because the ywheel may shatter during opera-

tion.

Check Tire Pressure

Tires should be checked periodically to provide the

optimum traction and to guarantee the best cut (see

Figure 4).

NOTE:

These pressures may di er slightly from the

“Maximum In ation” stamped on the side walls of the tires.

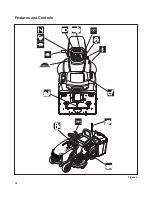

Summary of Contents for EMT17538RDF

Page 2: ...2...

Page 3: ...6 A B 7 A 5 A D B C 3 en...

Page 4: ...4 A A B A 10 11 12 B C 8 9 A C E A G G F H B D E...

Page 5: ...5 en 15 C 13 16 B A C A B D 14 A...

Page 6: ...6...

Page 16: ...Features and Controls Figure 2 16...

Page 32: ...32...

Page 42: ...Funkce a ovl d n Obr zek 2 16...

Page 58: ...32...

Page 68: ...Funktionen und Bedienelemente Abbildung 2 16...

Page 84: ...32...

Page 94: ...Fonctions et commandes Figure 2 16...

Page 110: ...32...

Page 120: ...Funzioni e comandi Figura 2 16...

Page 136: ...32...

Page 146: ...Functies en bedieningselementen Afbeelding 2 16...

Page 162: ...32...

Page 172: ...Funkcje i elementy sterowania Rysunek 2 16...

Page 188: ...Briggs Stratton Power Products Group LLC P O Box 702 Milwaukee WI U S A...