23

Number of bars flashing on display

Fault

Possible Cause

Ef

fect on Product

Investigate the Following

Action Required

If Fault

Persists.

* 6 Bars flash continuously

.

* Control system is Inhibiting drive.

* Faulty controller

.

* Machine will not operate.

* Check controller for water damage.

* Replace controller

.

*7 Bars flash once with pause

* Accelerator pedal trip.

* Accelerator pedal being activated without

seat switch being activated (nobody on seat)

Or seat switch momentarily deactivated while

accelerator pedal being activated during forward

/ reverse operation.

* Machine will not drive.

* Ensure accelerator pedal is not activated without

seat switch being activated. Ensure firm contact

with seat by operator at all times while accelerator

is pressed.

* Operator to be trained.

* 7 Bars flash twice with pause.

“ Emergency stop has been activated.

* Of

f aisle cleaning activated with floor

tool raised.

* Inadvertent pressing of emergency stop or

activation of of

f-aisle cleaning mode.

* Machine will not drive.

* Ensure emergency Stop button has not been

activated and of

f aisle vac switch is in of

f position

with floor tool raised.

* Reset emergency stop button. Switch of

f aisle

vac and raise floor tool.

* Cycle key switch to resume normal operation.

* 7 Bars flash 3 times with pause.

* V

ac Motor system short circuit.

* V

ac motor wiring fault / motor fault.

* V

ac motor will not operate.

* Check vacuum motor and wiring

* Replace motor and any damaged wiring.

* Cycle key switch to resume normal operation.

* 8 Bars flash continuously

.

* Control system trip.

* Seat switch failure.

* Machine does not operate.

* Check seat switch wiring.

* Replace wiring as required.

* 9 Bars flash once with pause.

* Flashing beacon failure to operate.

* Beacon short circuit.

* Flashing beacon does not operate

in accordance with safety require

-

ments.

* Check wiring and connections to device.

* Replace damaged components.

* Cycle Key switch to resume normal operation.

* 9 Bars flash 3 times with pause.

* W

ater pump failure to operate.

* Failure of pump or wiring short circuit.

* No water supplied to cleaning

heads.

* Check wiring and connections to pump.

* Replace damaged components.

* Cycle Key switch to resume normal operation.

* 9 Bars flash 4 times with pause.

* Detergent pump failure to operate.

* Failure of pump or wiring short circuit.

* No detergent supplied in water mix

to cleaning head.

* Check wiring and connections to pump.

* Replace damaged components.

* Cycle Key switch to resume normal operation.

* 9 Bars flash 5 times with pause.

* Solenoid brake circuit failure.

* Failure of solenoid or wiring.

* Machine will not move.

* Check wiring and connections to brake.

* Replace damaged components.

* Cycle Key switch to resume normal operation.

* 10 bars flash continuously

* Supply voltage to controller has

exceeded 40 volts.

* Battery and motor connections may have

become loose.

* Possible long term damage to

controller if fault persists.

* Check battery wiring, trio drive and motor

connections.

* Replace damaged components.

* Cycle Key switch to resume normal operation.

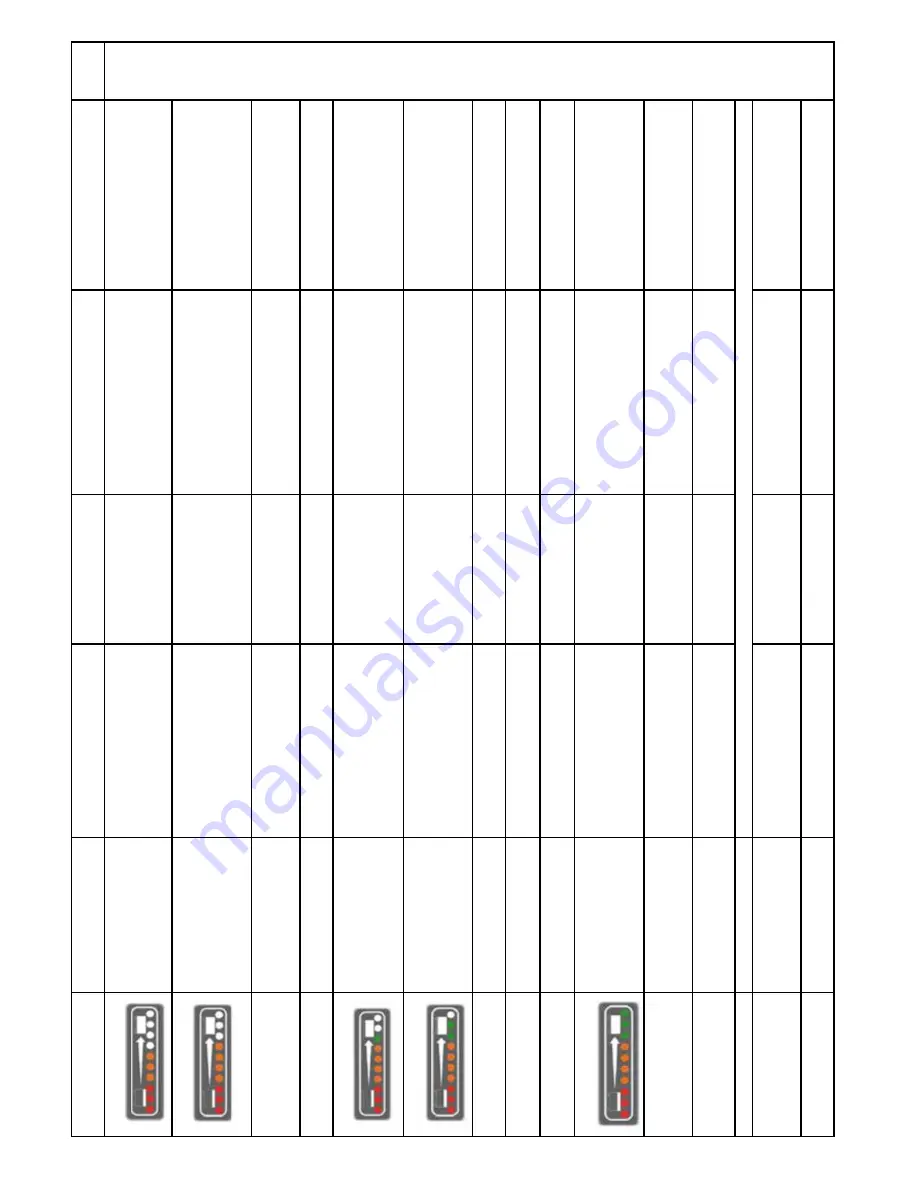

* Bars cycle up and down

continuously (from 1 to 10 and 10

back to 1) and repeats.

* Accelerator pedal movement

detected during V

ario start up se

-

quence (partially pressed or jammed).

* Foot or object on pedal during switch on or

possible jamming of pedal.

* Machine will not operate.

* Remove object and ensure pedal is not jammed

or depressed during switch on of V

ario.

* Cycle Key switch to resume normal

operation .

* Bars cycle from 1 to 10

continuously and repeats.

* Machine inhibit.

* Controller/harness incorrectly wired.

* Machine will not operate.

* Check controller and harness wiring with special

attention to wires p2/03 and p2/10.

*

Correct

wiring.

* Cycle Key switch to resume normal operation

* No indication on display

.

* Horn and beacon failure.

* Replace 20

Amp fuse (If this doesn’t fix fault replace horn or beacon)

* No indication on display

.

* Brush motors continuously either of

f

or on while in transport mode.

* Microswitch failure.

* Brushes will not operate correctly

.

* Check wiring and microswitch on underside of

machine by brushes ensuring microswitch is clear

of debris.

* Replace/clean damaged components.

* No indication on display

.

* V

AC motor continuously either of

f

or on.

* Microswitch failure.

* V

acuum will not operate correctly

.

* Check wiring and microswitchs behind floor tool

handle.

* Replace/clean damaged components.

Contact Service Agent.

Summary of Contents for TTV 678-300T

Page 26: ...26 WD 0359 A18 01 04 2014 ...

Page 27: ...27 ...

Page 29: ...29 Notes ...

Page 30: ...30 Notes ...

Page 31: ...31 Notes ...