4.1 Setting procedure

4-1

Chapter 4 Setting

4.1 Setting procedure

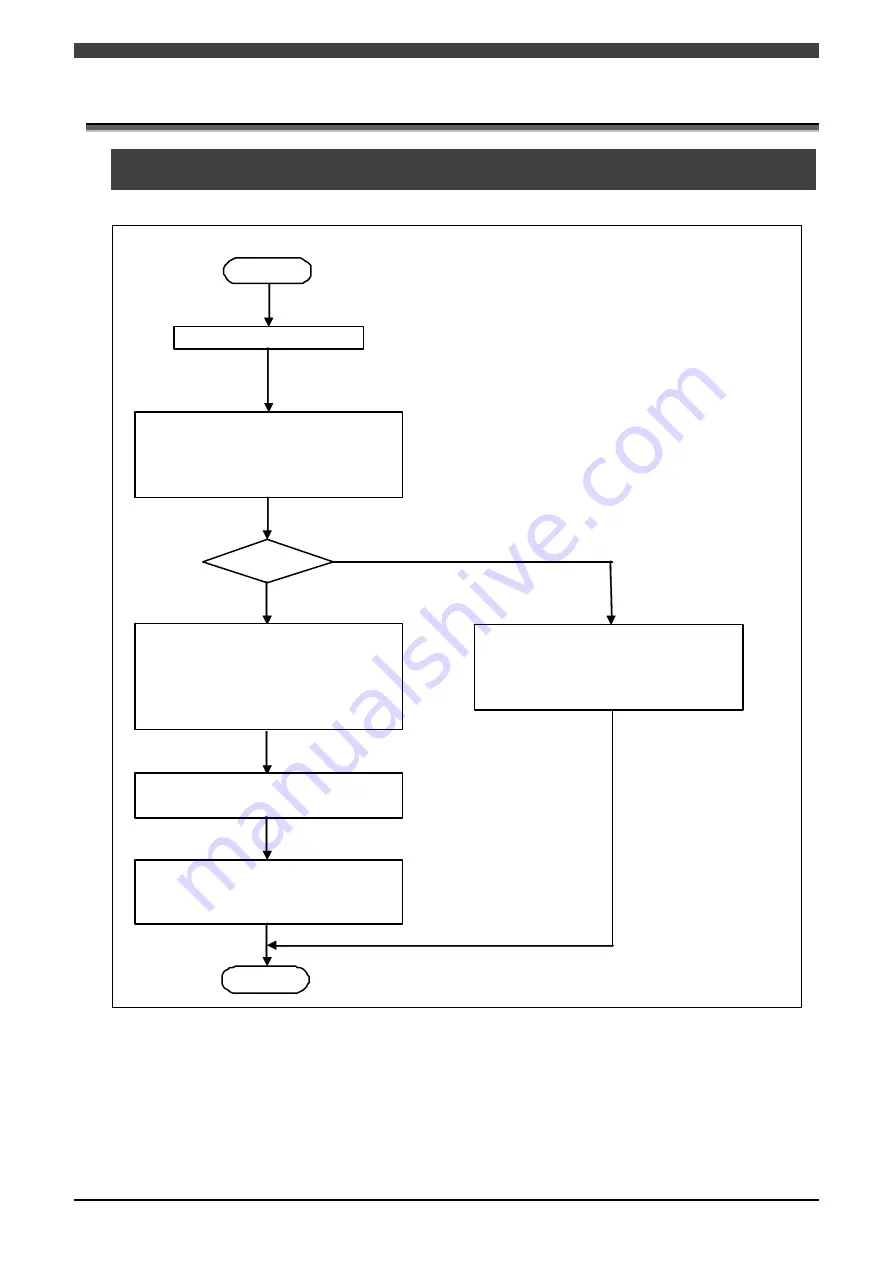

The basic flow of the setting procedure is given below.

Start

End

Hardware connections

Fieldbus setting

Set the slot ID and module number

where the fieldbus channel number,

master/slave, and EtherNet/IP board to

use are mounted .

Master?

EthernetIP(Master) settings

Set the IP Address, Subnet mask,

Defaultgateway, INPUT BYTES,

OUTPUT BYTES, the action to take

when transmission errors occur and

Execute Mode.

Sla ve list settings

Add or delete the slaves.

Slave parameter settings

Set the slave node n umbers of the sla ves

and the number of input/output bytes.

EthernetIP(Slave) settings

Set the IP Address, Subnet mask,

Defaultgateway, INPUT B YTES,

OUTPUT BYTES and the action to take

wh en transmission errors occur.

Fig. 4.1.1 Setting procedure flowchart

Hardware connections are carried out at time of factory shipment.

To set the scanlist, it is necessary to have the setting PC and RSNetWorx for EtherNet/IP (paid software) by

Rockwell.

When software PLC is used for fieldbus I/O, PLC setting procedure is required separately. For details, refer to

the instruction manual “Software PLC."

Summary of Contents for FD

Page 2: ......

Page 4: ...Table of Contents 2 ...

Page 10: ...2 1 Needed Parts 2 2 NOTE ...

Page 47: ......