2.3 Connected signals

2-19

2.3.4 Back check circuit

Table 2-15 Back check

Signal name

Circuit

code

Description

Electrical specifications

Robot power supply back

check 1+

Robot power supply back

check 1-

BK1+

BK1-

Signal from magnet switch “b” contact.

Signal for detecting the welding (back

check) of the magnet switch

When being used as a slave unit, this is

regarded as a weld stuck detection signal

for "Slave failure" output signal (back

check).

Photo-coupler input

Rating DC26V

Input current 5mA

Over current protection provided

General safety output 1

back check 1+

back check 1-

BK2+

BK2-

Signal from external safety relay and

magnet switch “b” contact

Signal for detecting the welding (back

check) of the magnet switch

Photo-coupler input

Rating DC26V

Input current 5mA

Over current protection provided

General safety output 2

back check 2+

back check 2-

BK3+

BK3-

Signal from external safety relay and

magnet switch “b” contact

Signal for detecting the welding (back

check) of the magnet switch

Photo-coupler input

Rating DC26V

Input current 5mA

Over current protection provided

General safety output 3

back check 3+

back check 3-

BK4+

BK4-

Signal from external safety relay and

magnet switch “b” contact

Signal for detecting the welding (back

check) of the magnet switch

Photo-coupler input

Rating DC26V

Input current 5mA

Over current protection provided

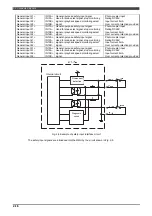

Back check circuit with over current protection and input diagnosis

A back check circuit is provided in the RMU in order to monitor the magnet switch contacts which are tripped

by the safety outputs. In the back check circuit, a safety contact (“b” contact) driven by the safety output and an

auxiliary contact (“b” contact) of the magnet switch are connected in series so that if the main contact ("a"

contact) of the relay melts down making it impossible to release the contact, the other safety output can still be

turned off to shut off drive power surely and stop the robot safely.

*) If the back check input is not inputted, a back check fault will be detected when the output is ON.

Summary of Contents for RMU20-20

Page 2: ......

Page 6: ...Contents 4 ...

Page 8: ......

Page 26: ...1 4 EC DECLARATION OF CONFORMITY FOR MACHINERY 1 18 NOTE ...

Page 68: ...2 9 Enabling RMU 2 40 NOTE ...

Page 70: ......

Page 100: ...3 4 Setting when a slider unit is used 3 30 NOTE ...

Page 102: ......

Page 138: ...4 4Approval 4 36 8 Approval is completed The following screen will be displayed ...

Page 144: ......

Page 154: ...5 4Trouble shooting 5 10 NOTE ...

Page 156: ......

Page 166: ...6 4Trouble shooting 6 10 NOTE ...

Page 168: ......

Page 189: ......