Page-5

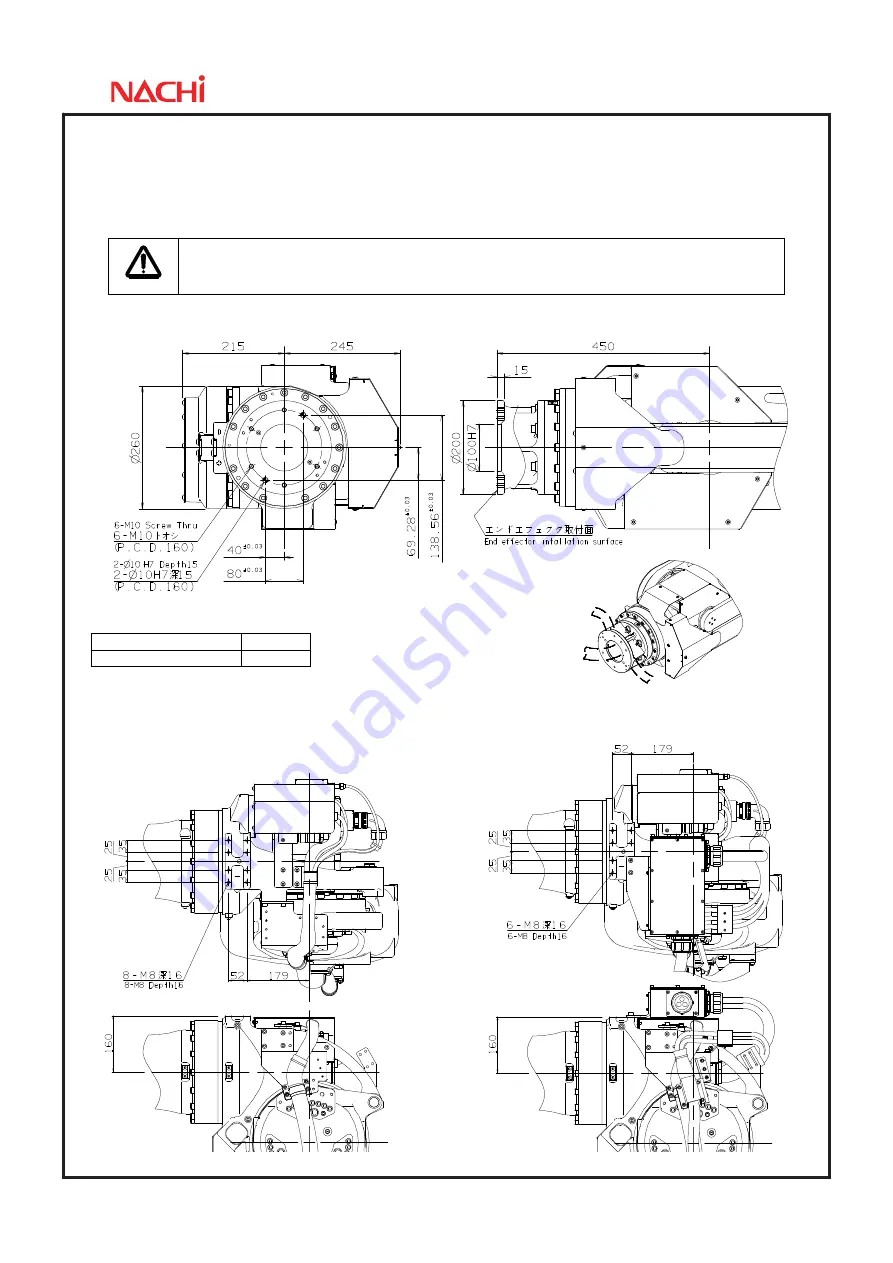

4. Detail of load mounting plate

■ Wrist

For the end effecter fixing bolts, use the mounting P.C.D. shown in the following figures.

Another P.C.D. is prepared as option. Consult with each NACHI-FUJIKOSHI office for the details.

CAUTION

Be sure to screw the M10 tool fixing bolts in the wrist not deeper than the screw depth in

the mounting face. Screwing the bolts deeper than the screw depth may damage the

wrist.

【

SRA220H-01

】【

SRA220HV-01

】

■ Upper part of forearm

Ancillary equipment can be mounted to the upper part of robot forearm.

(In case of spot welding specification, mounting tap is restricted because joint box is mounted.)

【

Spot welding specification

】

【

Standard specification

】

※

Cable inside arm can be accessed

from 3 directions those are front

and both side of end effecter.

Tightening torque of

M10 Hex. socket head cap screw

JIS: Strength class 10.9

55 N

・

m

JIS: Strength class 12.9

67 N

・

m

Summary of Contents for SRA220H Series

Page 1: ...Standard specifications SRA220H 01 FD11 SRA220HV 01 FD11 7th edition 1707 SSRAEN 064 007 001 ...

Page 5: ...Page 3 3 Robot dimensions and working envelope SRA220H 01 ...

Page 6: ...Page 4 SRA220HV 01 ...

Page 11: ...Page 9 SRA220HV 01 Robot type ...

Page 20: ...Page 18 8 2 Spot welding specification 2 Connecting diagram Standard ...

Page 25: ......