10

TY-GC62-010A Rev.2

5. Installation and removal

For installation, select a place with less vibration, without exposure to direct sunlight, with

less humidity and little dust, and not exposed to water or oil. When using one of the pressure

connection ports open to the atmosphere, avoid places where the pressure on the

open-to-atmosphere side fluctuates (where the wind directly hits for example). When

installing in such a place, please consider preventive measures such as extension of the

tube to where there is no impact of pressure fluctuation of the atmosphere open side.

Since the main body is made of resin, please be careful not to apply a

large force, and not make scratches.

■

5.1 Piping

We are offering a model that comes with apparatus for piping for this product. Please

contact the sales office for details.

Make sure to pipe the high pressure side of the applied pressure to the

connection port “H” and the low pressure side to the connection port “L”.

The pressure connection ports of the panel mount model are located on the rear side (L

and H 1 each) and on the side (L and H 1 each). Use the connection port of L and H to be

used, and fill in the other unused ports (other L and H) using the hexagon socket head plug

all way up to the main body. When the plug is used repeatedly, wrap with the seal tape and

block it so as to prevent leakage. In that case, tightening torque to the screw part should

be 1 N m or less. Torque is for the hexagon socket head plug.

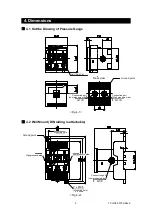

(1)

Panel mount

Insert the main body through

the panel cutout and insert the panel adapter from the

back side. Insert the panel adapter until the gap between the panel and the panel

surface is minimized, then fix it using the attached screws. Do not overtighten the

screws.

When installing the products on the panel one after another, keep the

spacing between the panel cutout 3 mm or more left and right, 13 mm or

more above and below.

<Fig.5-1>

Panel cutout

Panel mount drawing

Panel (thickness range: 1 to 4mm)