4

Y-KH15-007A Rev.3

TABLE OF CONTENTS

FOR PROPER AND SAFE USE ................................................... 2

TABLE OF CONTENTS ................................................................ 4

1. INTRODUCTION ....................................................................... 6

2. PRODUCT OVERVIEW ............................................................. 6

3. MODEL NUMBER CONFIGURATION ...................................... 7

4. SPECIFICATIONS ..................................................................... 8

5. DIMENSIONS ............................................................................ 9

(small terminal box) ..................................................................... 9

(large terminal box) ................................................................... 10

6. TRANSPORTATION AND UNPACKING ................................. 11

7. INSTALLATION AND REMOVAL ............................................ 11

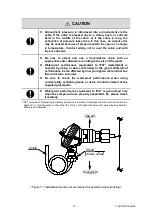

7.2 Precautions for Possible Water Sprinkling .................................................. 12

8. WIRING AND CONNECTION .................................................. 14

8.3 Wiring Diagram and External Connection .................................................... 17

9. OPERATION (ENERGIZATION) .............................................. 18

10. MEASURES AGAINST NOISE ............................................. 18