TY-KJ16-001A

4/25

5-2

.

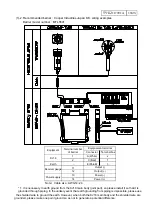

General Specification

Item

Specification

Standard

Tip diaphragm type

1. Pressure range

-0.1

~

0.5, 1, 2MPa

0

~

0.5, 1, 2, 3.5, 5, 10, 20, 35, 50, 70,

100MPa

(KJ16-

□□

G is 35 MPa or less)

0

~

1, 2, 3.5, 5, 10MPa

2. Allowable maximum

pressure

*1

SUS630

CO-Ni

200%

35, 50MPa

:

150%

70, 100, 120MPa

:

120%

SUS630

200%

SUS316L

150%

3.5

~

35MPa

:

120%

3. Accuracy

*2

±0.5%F.S.

(

at 23

℃

)

±1.0%F.S.

(

at 23

℃

)

4. Temperature coefficient

(ZERO,SPAN)

SUS630

CO-Ni

±0.05%F.S./

℃

(50MPa or less)

±0.1%F.S./

℃

(70,100MPa)

±0.1%F.S./

℃

SUS316L

±0.1%F.S./

℃

5. Connection

G1/4B, G3/8B, G1/2B

R1/8, R1/4, R3/8, R1/2

(50MPa or less)

9/16-18UNF

(Made by Autoclave Engineers ,

Equivalent to F250C)

G3/8A

(Recommended tightening torque:

30N.m)

6. Wetted parts

Material

Standard

Diaphragm

Joint

:SUS630(17-4PH)

:SUS316

Diaphragm

Joint

O-ring

:SUS630(17-4PH)

:SUS316

:

Hard NBR

Corrosion

proof use

Diaphragm

Joint

:SUS316L

:SUS316L

(35 MPa or less)

High

corrosion

proof use

Diaphragm

Joint

:Co-Ni

:SUS316

EPDM,

Fluororubber ,Neoprene etc.

Available

7. Fluid

Gas or liquid (Not corrosive to the wetted material)

8. Power supply

24V DC±10%

9. Output

4

~

20mA DC (2 wire system)

10. Load resistance

500

Ω

max.

275

Ω

max. (When using the recommended zener barrier)

11 Case material

ADC12

12.Protection class

Eguivalent to IP65 ( IEC standard)

13. Type

Connector type

Terminal box type (Large, Small)

14. Operating temperature

and humidity

-

10

~

60

℃

, 35

~

85%RH (No freezing or condensation)

15. Storage temperature

and humidity

-

20

~

70

℃

, 35

~

85%RH (No freezing or condensation)