13

TY-KJ55-002A Rev.3

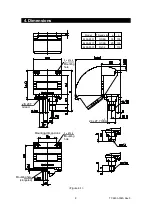

(1) System configuration diagram

(2)

Intrinsically safe equipment and safety barrier

The intrinsically safe equipment must be paired with the safety barrier to satisfy

the conditions in the two tables below so that the intrinsically safe performance

can be secured. Be sure to observe the following pairing conditions (See "3.2

Intrinsically Safe Specifications").

Pairing conditions for safety holding ratings

Safety holding rating for

intrinsically safe equipment

Pairing condition

Safety holding rating for

safety barrier

Allowable voltage of

intrinsically safe circuit

≥

Maximum voltage of

intrinsically safe circuit

Allowable current of

intrinsically safe circuit

≥

Maximum current of

intrinsically safe circuit

Allowable power of

intrinsically safe circuit

≥

Maximum power of

intrinsically safe circuit

Hazardous area

Non-hazardous

area

Intrinsically safe

equipment

(KJ55)

Safety barrier MTL5541 (insulating barrier)

Power supply

20 to 35 V

Receiving

device

+

-

(Ground)

+

-

+

-

+

-

+

-

+

-

2

1

14

13

12

11

E

Device

Terminal No.

of the barrier

Equipment terminal

1

POWER (-)

2

POWER (+)

Ground

GND

11

Output (-)

12

Output (+)

13

Power supply (-)

14

Power supply (+)

Power supply

KJ55

Receiving device

<Figure 7-2>

<Table 7-3>

<Table 7-4>