DF Series installation manual

24

www.nagasinnovation.com

NOTE:

Refer to the normal operating sequence and the service check list below to identify

possible causes of problems.

The Honeywell S7800A Keyboard module displays the following trouble codes which

are the most important ones with regard to the operation of the heater.

(Refer to the manufacturer for any code not listed below.)

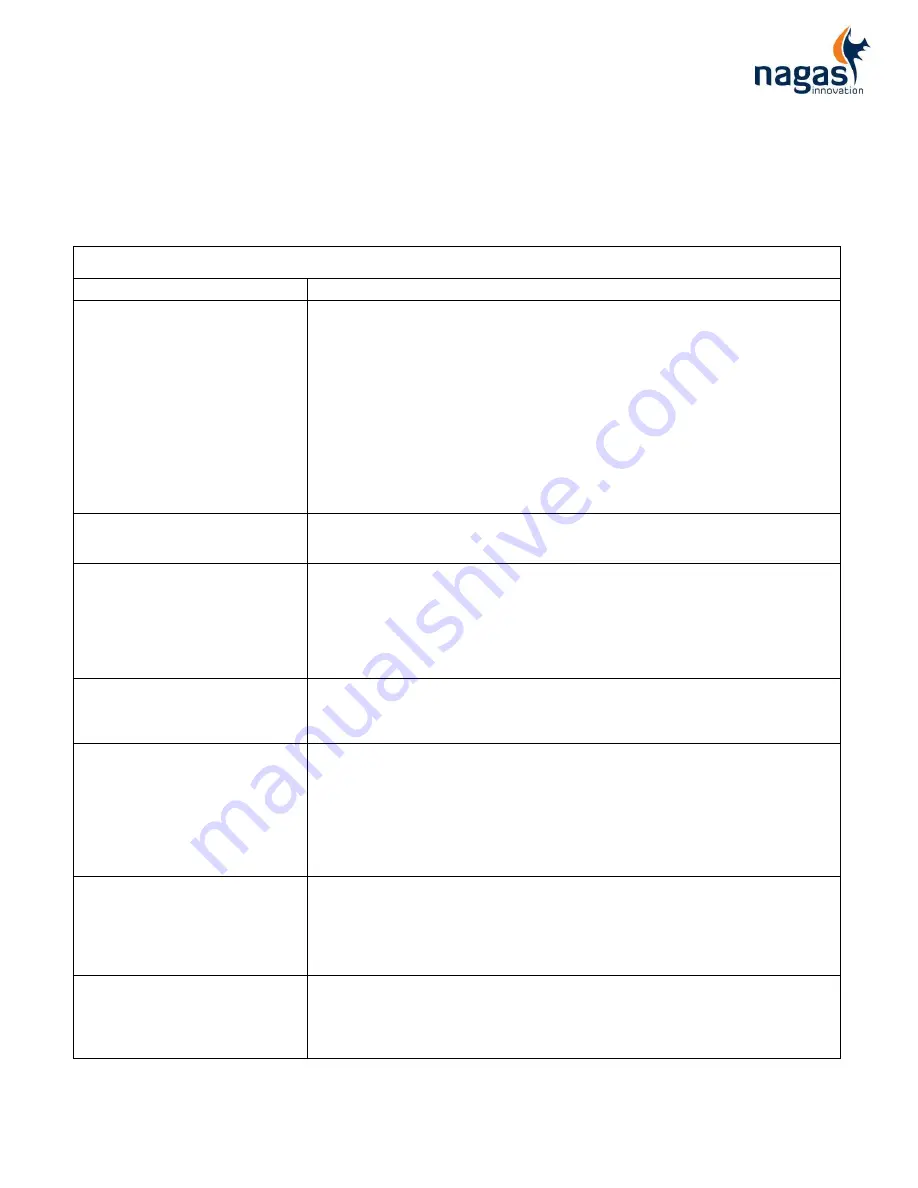

FIREYE AND HONEYWELL TROUBLESHOOTING CHECK LIST

SYMPTOMS

ACTIONS

✓

THE BLOWER IS NOT IN OPERATION.

✓

THE BURNER IS NOT IN OPERATION.

✓

THE FRESH AIR DAMPER IS CLOSED.

1. Turn ON main disconnect switch.

2. Check the input voltage.

3. Check 120-volt secondary circuit fuse.

4. Check the position of the switch on the remote control panel; it should be set to BURNER.

5. Check the contactor indicating that the exhaust fan is in operation.

6. Press down the reset button of the (FIREYE or HONEYWELL) flame safeguard relay if an

ALARM light flashes.

7. Check the adjustment of the overload relay of the blower motor; re-adjust it if necessary.

8. Check the freeze protection control; its contact opens after around 300 seconds if the

supplied temperature remains under 42°F. To start the heater, set the burner and blower

switch located on the remote control panel to STOP and then to BURNER

9. Refer to the manufacturer.

✓

THE BLOWER IS NOT IN OPERATION.

✓

THE BURNER IS NOT IN PERATION.

✓

THE FRESH AIR DAMPER IS OPEN.

1. Make sure that the fresh air damper switch is closed.

2. Refer to the manufacturer.

✓

THE BLOWER IS IN OPERATION.

✓

THE BURNER IS NOT IN OPERATION.

✓

THE FLAME SAFEGUARD RELAY IS

OPERATING NORMALLY.

1. Check if the auxiliary contact of the blower motor starter works.

2. Check selector position on the remote control panel; it should be set to BURNER.

3. Check the outside temperature thermostat; it prevents the burner from running if the

outside temperature is over 70°F.

4. Check the burner purge time delay relay.

5. Refer to the manufacturer.

✓

FREQUENCY NOISE

CODE 6 FIREYE

1. Check if a high voltage source is located near the flame safeguard relay.

2. Check electrical wiring from the building junction box to the heater.

3. Refer to the manufacturer.

✓

FLAME FAILURE (PTFI)

CODE 7 FIREYE

CODE 28 HONEYWELL

NOTE: The flame safeguard relay goes

into alarm mode during the pilot

ignition cycle.

1. Check gas supply to the pilot.

2. Check pilot ignition transformer.

3. Check flame signal intensity (pilot only; it should range between 5 and 10 VDC for FIREYE or

between 3 and 5 VDC for HONEYWELL).

4. Check if manual and electric pilot gas supply valves are open.

5. Check condition of the flame rod ceramic; replace the flame rod if necessary.

6. Check or replace the flame safeguard relay amplifier.

7. Refer to the manufacturer.

✓

FLAME FAILURE (MTFI)

CODE 19 FIREYE

CODE 17 HONEYWELL

NOTE: The flame safeguard relay goes

into alarm mode during the main

burner ignition period.

1. Check if there has been a gas supply cut-off while the heater was in operation.

2. Check the inlet gas pressure while the burner is in operation.

3. Check the intensity of the flame signal (while the burner is in operation; it should be

between 5 and 10 VDC for FIREYE or between 3 and 5 VDC for HONEYWELL over the entire

modulation range).

4. Refer to the manufacturer.

✓

FLAME FAILURE

CODE 19 FIREYE

NOTE: The flame safeguard relay goes

into alarm mode during the first 10

seconds of the ignition cycle.

1. Check the main burner pipes and the electrical connections.

2. Check condition of the flame rod ceramic; replace the flame rod if necessary.

3. Check the intensity of the flame signal (between 5 and 10 VDC for FIREYE or between 3 and

5 VDC for HONEYWELL).