Page 16

Instruction manual 5900110x

Version 1 July-08

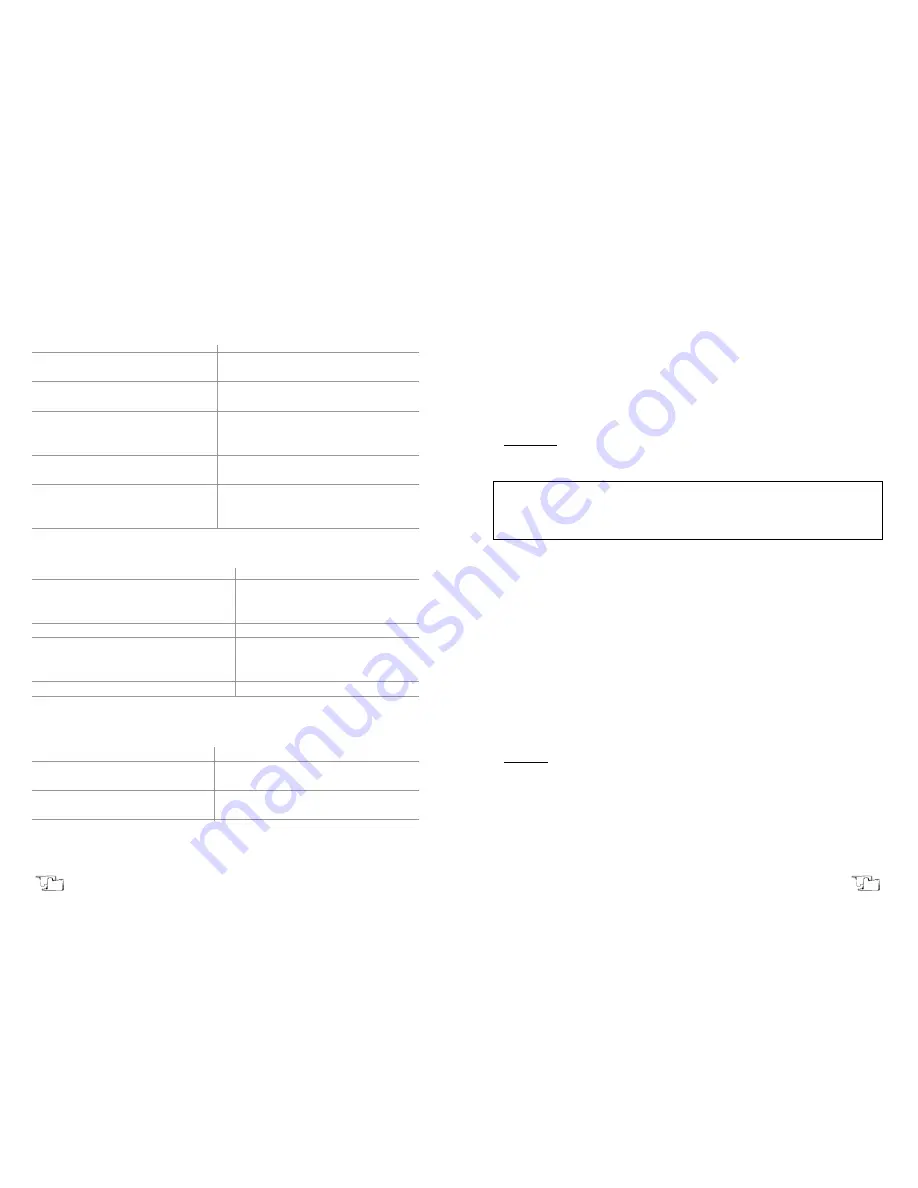

2) The pump does not make a good vacuum or spends more time than expected.

CAUSE

SOLUTION

The oil is contaminated

Drain the contaminated oil and add new

oil

There are leaks or losses in the

Review the vacuum hose to detect

vacuum system

possible leaks

The level of oil is not enough

Stop the pump and add oil until reaching

the correct level if the oil is in perfect con-

ditions of use. If not, change the oil.

Loss of oil due to a defect of

Contact the Nahita Technical

the pump

Assistance Department

Internal parts of the pump damaged

Contact the Nahita Technical

or worn out by the use or a bad

Assistance Department

lubrication

3) The pump starts but presents a high electric consumption (amperage).

CAUSE

SOLUTION

The oil is too dense (high viscosity)

Use a lower viscosity oil

or environmental temperature is

lower than 5 ºC

The pump is overloaded with oil

Remove the excess of oil

Foreign bodies inside the pump;

Contact the Nahita Technical

broken vanes; damaged or blocked

Assistance Department

bearings

Low tension

Verify the tension used

4) The pump is very noisy when operating

CAUSE

SOLUTION

Connection worn out or loosen

Contact the Nahita Technical Assistance

Department

Bearings damaged

Contact the Nahita Technical Assistance

Department

Version 1 July-08

Instruction manual 5900110x

Page 13

the accessories supplied.

Please check that all the accessories are enclosed with the equipment:

- Oil bottle, 250 mL

- User’s manual

- Warranty certificate

We will only accept any equipment return within 15 days after delivery and provided

it comes in its original wrapping.

Installation

Before using the vacuum pump, it is convenient for you to familiarize with its compo-

nents and basic essentials, as well as with its control functions.

PLEASE READ THOROUGHLY THE INSTRUCTIONS BEFORE CONNECTING

AND OPERATING WITH THIS EQUIPMENT WITH THE AIM OF ACHIEVING

THE HIGHEST FEATURES AND THE MAXIMUM DURABILITY OF THE INS-

TRUMENT

Put the pump on top of a horizontal, plane and stable surface so as vibrations produced

during operation do not disturb nearby equipments. The back side of the pump must be

perfectly ventilated and free of obstructions.

Do not put the pump near any warm supply (burners, blowlamps…), nor expose it

directly to the sun, etc. During operation, flammable liquids must be out of the working

area.

Open the oil inlet cap

(1.5)

and fill the pump until the oil level reaches the middle of the

sight glass

(1.4)

.

Make sure that the switch

(1.2)

is off and insert the Schuko wire that feeds the AC elec-

tric current in the base of current 220 V, 50 Hz ± 10% provided with earth wire.

Neither the manufacturer nor the distributor will assume any responsibility for the

damages produced to the equipment during its installation or damages to persons suf-

fered by the improper use of the electric connection. The tension should be 220 V, 50

Hz ± 10%.

Setting up

High vacuum pumps are designed to offer highly satisfactory results for a long time

and don’t need a special assembly.

The aeration hose must be flexible to avoid a possible transmission of vibrations, water-

tight and with the same or higher calibre than the pump connection (depending on the

distance to cover) to obtain an optimum output.

Note: model 59001102 presents double vacuum connection. During operation, the con-

nection that is not in use must be perfectly protected by its cap (1.8) to avoid leaks.

ENGLISH

ENGLISH