SCHEDULE TYPE:

PROJECT:

ENGINEER:

CONTRACTOR:

DATE

B SERIES

SUPERSEDES DRAWING NO.

5 - 7 - 12

1200

3 - 21 - 11

1210SS-3

STAINLESS STEEL SMOKE DAMPER

AIRFOIL BLADE • HIGH PERFORMANCE

ULTRA-LOW LEAKAGE

ROUND DUCT CONNECTION

MODEL: 1213SS (TYPE C SLEEVE ENCLOSURE)

Nailor Industries Inc. reserves the right to change any information concerning product or pricing without notice.

Dimensions are in inches (mm).

The 1210SS Series dampers are ideal for high humidity, mildly corrosive

or, with optional Type 316 construction, more severe environments where

building codes require a leakage rated smoke damper as part of a static

smoke control or dynamic smoke management system.

The 1210SS Series has been especially designed and tested to offer

premium performance. The 1210SS Series provides the lowest leakage

class available and is qualified for vertical or horizontal installation with

airflow in either direction. Airfoil blade design and elimination of blade

sills, top and bottom, provide lowest pressure drop. Unique inter-locking

double skin blade design eliminates combustible blade seals and provides

flame and smoke seal under fire conditions.

STANDARD SPECIFICATION:

Frame:

5" x 7/8" x 16 ga. (127 x 22 x 1.6) stainless steel hat channel.

Blades:

14 ga. (2.0) equivalent stainless steel formed airfoil on

5 1/2" (140) centers.

Linkage:

Concealed in frame. 12 ga. (2.7) stainless steel.

Bearings:

1/ 2" (13) dia. sintered stainless steel.

Axles:

1/ 2" (13) dia. stainless steel double bolted to blades.

Jackshaft:

1/2" (13) dia. stainless steel.

Jamb Seals:

Cambered stainless steel.

Sizes (Duct Diameter):

SLEEVE/ENCLOSURE SELECTION:

❑

1213SS

Standard factory sleeve (caulked to UL requirements)

16" long x 20 ga. (406 x 1.0) (18 ga. for dampers over

84" [2134] in width).

❑

1213SS

Non-standard sleeve. Specify _______ length _____ ga.

Available up to 36" (914) in length and 10 through 20 ga.

(3.5 through 1.0).

CONSTRUCTION TYPE:

❑

304

Type 304 Stainless Steel construction (Standard).

❑

316

Type 316 Stainless Steel construction (Optional).

LEAKAGE CLASS / ELEVATED TEMPERATURE:

❑

I

❑

II @ 250°F

DYNAMIC VELOCITY/PRESSURE RATING:

24

2000 fpm @ 4" w.g.

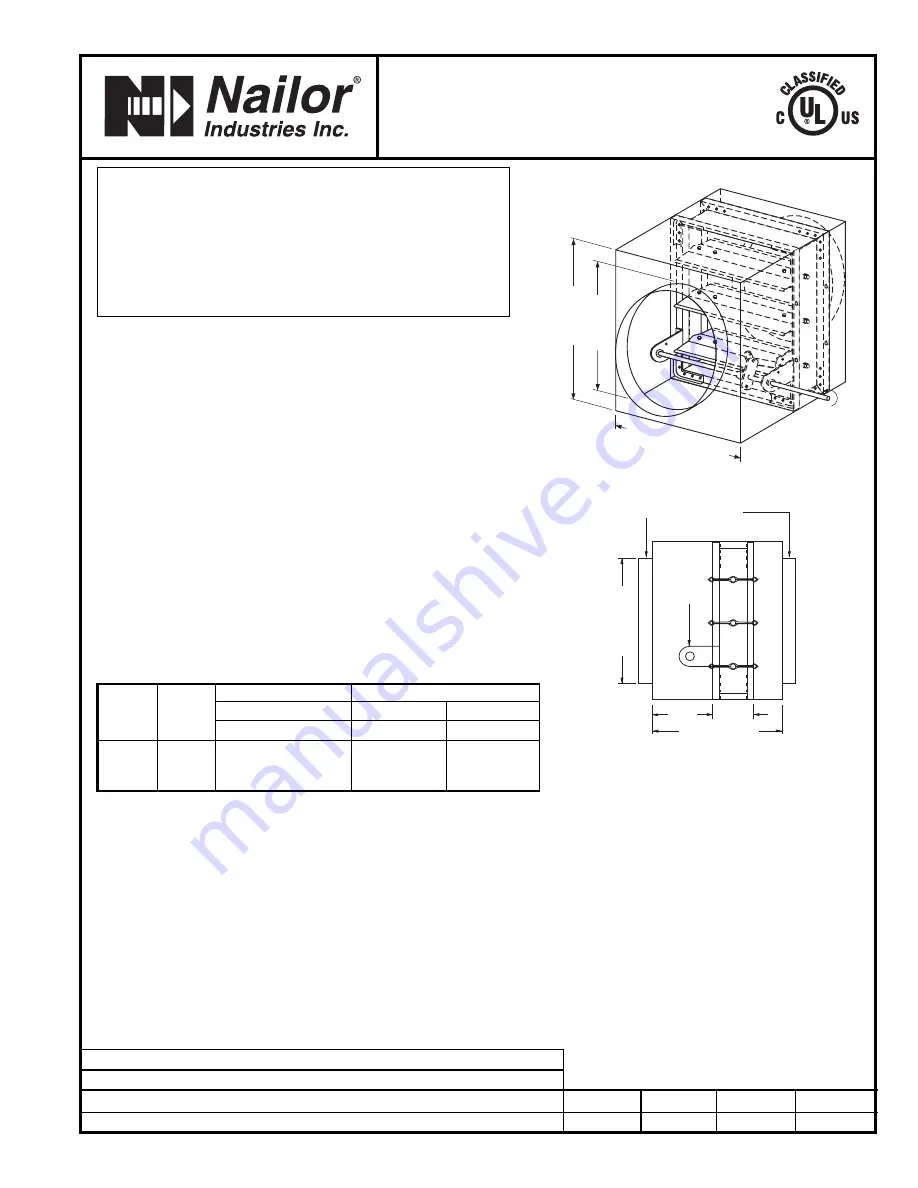

'C' ENCLOSURE BOTH ENDS

D –

1/8" (3)

(D –

1/4" (6)

OVER

36"

(914))

16" (406) STANDARD

5" (127)

8" (203)

STANDARD

JACKSHAFT

ACTUATOR SELECTION:

❑

Electric

❑

Pneumatic

ACTUATOR LOCATION:

❑

External

(std.)

❑

Internal

(in the airstream)

ACTUATOR FAIL POSITION:

❑

Normally Closed

(std.)

❑

Normally Open

OPTIONS:

❑

MLS-300

Position indicator switch pack

For installation instructions, see IOM-SDINST.

D + 2" (51) (MIN.

8

" [20

3

])

D =

NOM.

DUCT

DIA.

D

+

2"

(51)

CCW

TO

OPEN

*

*

or 8" (203) min.

QUALIFICATIONS:

• UL 555S CLASSIFIED SMOKE DAMPER (File # R9492)

Leakage Class I or II at 250°F elevated temperature.

• Meets NFPA 90A, 92A, 92B, 101 and 105 as well as IBC and

NBC (Canada) Building Code requirements.

• California State Fire Marshal Listing No. 03230-0935:107.

• City of New York MEA# 366-03-M.

• Maximum velocity: 2000 fpm@ 4" w.g.

Velocity/

Pressure

Rating

Elevated

Temp.

°F

Minimum

Maximum

Single Section

Single Section

Multiple Section

Vertical/Horizontal

Vertical/Horizontal Vertical/Horizontal

24

250

4" (102) dia.

(Overall damper size is

8" x 8" [203 x 203] minimum).

34" (864) dia.

94" (2388) dia.