Technical Data

1446

Power Supply

24 VAC, ±20%, 50/60 Hz, 24 VDC, 0% /

+50%

Power consumption in operation 27 VA

Power consumption in rest

position

3 W, 6.5 VA, End stop 55 VA, 2.5 A slow

blow fuse *

Transformer sizing

40 VA (class 2 power source)

Shaft Diameter

1/2” to 1.05” round, centers on 1/2” and

3/4” with insert, 1.05” without insert

Electrical Connection

18 GA, 3 ft [1 m], 2 color coded wires

Overload Protection

electronic throughout 0° to 95° rotation

Electrical Protection

actuators are double insulated

Angle of rotation

95°

Torque motor

70 in-lb [8 Nm] from 32...350°F [0...177°C]

direction of rotation motor

reversible with CW/CCW mounting

direction of rotation spring-return reversible with cw/ccw mounting

Position indication

visual indicator, 0° to 95° (0° is full spring

return position)

Running Time (Motor)

15 sec between 32...350°F [0...177°C], <15

sec at rated voltage & torque

Running Time (Fail-Safe)

15 sec

Ambient humidity

5...95% r.H. non-condensing

Ambient temperature

32...122°F [0...50°C]

Non-operating temperature

-40...176°F [-40...80°C]

Degree of Protection

IP40, NEMA 1

Housing material

zinc coated steel

Gears

steel, permanently lubricated

Agency Listing

cULus listed to UL873 and CAN/CSA C22.2

No.24, UL 2043 Listed for air plenum

installation per NEC 300.22 and IMC

Section 602

NYC Department of Buildings MEA 197-

07-M.California State Fire Marshal Listing

3210-1593:101.

Noise level, motor

45 dB (A) motor, 62 dB (A) spring,

inaudible holding

Maintenance

maintenance free

Quality Standard

ISO 9001

Weight

5.71 lb [2.8 kg]

† UL File XAPX.E108966

Fire & Smoke damper actuator

Application

The type FSNF spring-return actuator is intended for the operation of smoke

and combination fire and smoke dampers in ventilation and air-conditioning

systems. The actuator will meet requirements of UL555 and UL555S when

tested as an assembly with the damper and will meet requirements of UBC for

15 second opening and closing at 350°F. Square footage of damper operated

will depend on make and model and the temperature required.

IMPORTANT 24VDC NOTE: The FSNF24 & -S models will not operate below

24VDC. A filtered and regulated power supply must be used.

Operation

Mounting of the actuator to the damper axle shaft or jackshaft (3/8” to 1.05”) is

via a cold-weld clamp. Teeth in the clamp and V-bolt dig into the metal of both

solid and hollow shafts maintaining a perfect connection. The specially designed

clamp will not crush hollow shafts. The bottom end of the actuator is held by an

anti-rotation strap or by a stud provided by the damper manufacturer.

The actuator is mounted in its fail safe position with the damper blade(s) closed.

Upon applying power, the actuator drives the damper to the open position. The

internal spring is tensioned at the same time. If the power supply is interrupted,

the spring moves the damper back to its fail-safe position.

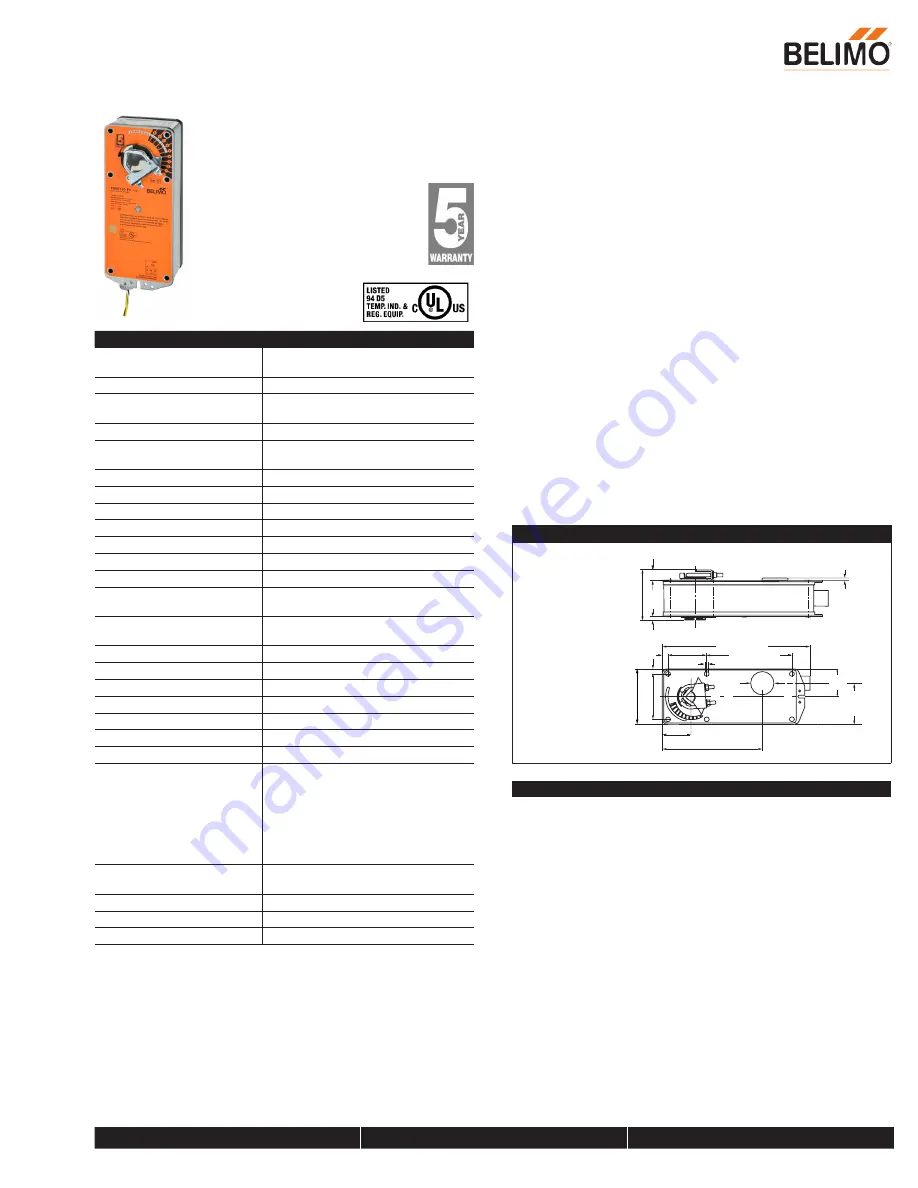

Dimensions (Inches[mm])

Standard:

1/2" to 1.05"

Optional*

3/8" to 3/4"

*with K4 US clamp

1.97"

3.15" [80

]

3.86" [98

]

2.24" [57]

[5

]

[50]

1.93" [49]

2.89" [73.5]

2.64"

[67]

0.26" [6.5]

5.85" [148.5]

10.20" [259]

0.35" [9]

0.39" [10]

0.65" [16.5]

0.19" [5]

[ø41.2]

ø1.62"

[191.6]

7.54"

0.19"

3.25" [82.7]

Safety Notes

* Neither UL nor Belimo require local over-current protection. The FSNF

actuators draw higher peak current when driving against any type of stop. If

used, this requires the value of a local fuse or breaker to be increased to avoid

nuisance opening or tripping. A 2.5 amp slow blow should be used for 24VAC.

A 0.5 amp slow blow should be used for 120 VAC. A 0.25 amp slow blow

should be used for 230V and a 0.3 amp slow blow for 208 VAC. Transformers:

Note that while a 24V 100VA transformer would handle 2 actuators, a 4 A

breaker or plug fuse is insufficient. A 5 amp slow blow would be required.

Belimo Fire & Smoke actuators have passed the AMCA 520 and UL 555S Long

Term Holding test. No special cycling is required during prolonged periods

when actuator is driven open and held there. Periodic testing of dampers and

actuators per local codes and NFPA 80 and NFPA 105 are required.

The actuator contains no components which the user can replace or repair.

A 1/2” threaded connector is standard. FSNFxx-FC models have a 3/8” Flex

Connector. Other than the connector, these actuators are identical to the

conduit connector version.

⚠

WARNING: For Belimo Products sold in California, these Products do or

may contain chemicals which are known to the State of California to cause

cancer and or birth defects or other reproductive harms. For more information

see www.p65warnings.ca.gov.

FSNF24 US

On/Off, Spring Return, 350°F [177°C] for a half hour, 15 Seconds Cycle Time

800-543-9038 USA

866-805-7089 CANADA

203-791-8396 LATIN AMERICA / CARIBBEAN

Date created, 04/10/2019 - Subject to change. © Belimo Air

controls (USA), Inc.