Nailor Industries Inc. reserves the right to change any information concerning product or specification without notice or obligation.

Page 2.080

11/09 IOM-1290FINST

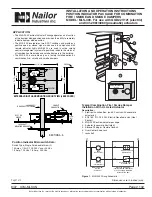

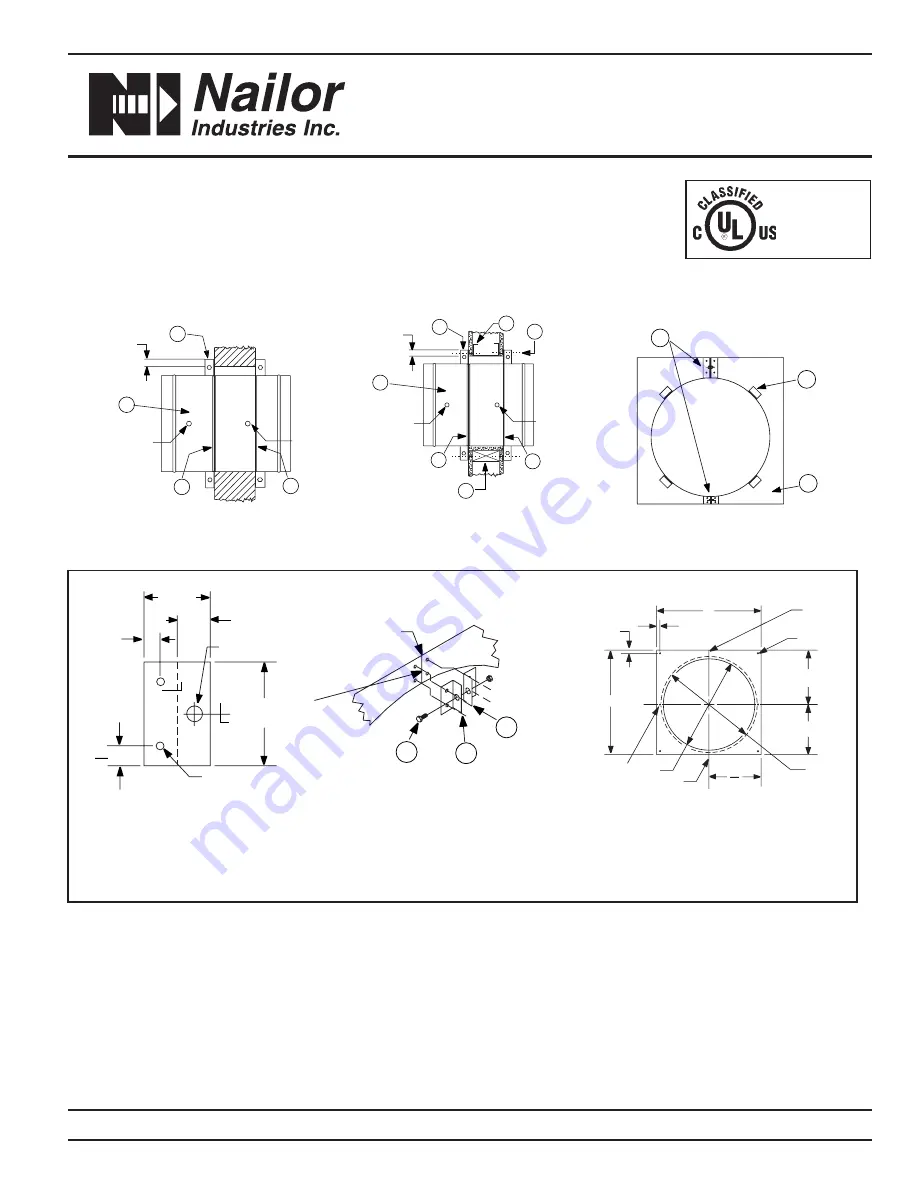

INSTALLATION INSTRUCTIONS: MODELS 1290F & 1290F-SS

TRUE ROUND FIRE DAMPER

1 1/2 HOUR LABEL • FOR USE IN DYNAMIC OR STATIC SYSTEMS

VERTICAL OR HORIZONTAL MOUNTING

Dimensions are in inches (mm).

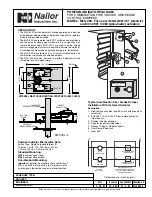

Blade

Shaft

Actuator

Driveshaft

1" (25)

Min. Typ.

1

2

3

4

Actuator

Driveshaft

Blade

Shaft

1" (25)

Min. Typ.

1

2

3

4

5

7

5

Steel or Wood

6

3

4

2" (51)

1/2" (13)

1" (25)

H

4

1/8" (3) Ø

1/4" (6) Ø

C

90º B

B

H = cutline

- 1/8" (3)

9

8

Cutline on

damper/retaining

plate

4

B

1/2" (13) Typ.

A

1/2" (13) Typ.

R + 1

R + 2

3/16" Ø (5)

D1

D2

B

2

Cut

Cut

2 additional holes/screws

required when single side

retaining plate is used.

See note 5 on page 2.

A and B = Nom. Damper dia. plus 3" (76)

D1 = Nom. Damper dia. minus 3/16" (5) for Retaining Plate

D2 = Nom. Damper dia. for Damper Plate

R = Nom. Damper Radius

ITEMS:

1.

Model 1290F or 1290F-SS fire damper.

2.

Retaining Plate, 20 gauge (1.0) galvanized steel (1290F) or stainless steel (1290F-SS).

3.

Damper Plate, 20 gauge (1.0) galvanized steel (1290F) or stainless steel (1290F-SS).

4.

Splice clips, 20 gauge (1.0) galvanized steel (1290F) or stainless steel (1290F-SS), two pairs for each plate.

5.

Steel or wood runner.

6.

Retaining clip - 1" x 1" x 1" (25 x 25 x 25) 20 gauge (1.0) galvanized steel (1290F) or stainless steel (1290F-SS) angle (see note 5).

7.

#10 sheet metal screw

8.

1/8" (3) dia. steel pop rivet, or #10 x 1/2" (13) sheet metal screws, or tack or spot welds.

9.

1/4" (6) dia. x 1" (25) long nut and bolt for securing splice clip halves together.

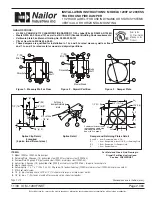

Figure 1. Masonry Wall or Floor

Figure 2. Drywall Partition

Splice Clip Detail,

8 required

(4 pairs, two different sizes)

Splice Detail

Damper and Retaining Plates Detail

Figure 3. Damper Plate

For Metal and Wood Stud Framing in

Drywall Partitions instructions;

See doc. FDSWSFINST

Page 1 of 2

QUALIFICATIONS:

•

UL 555 & CAN/ULC-S112 CLASSIFIED FIRE DAMPER 1 1/2 hr. Label (File #’s R9492 & R19569).

•

Meets NFPA 80, 90A and 101 as well as IBC & NBC (Canada) Building Code requirements.

•

California State Fire Marshall Listing No. 03225-0935:101.

•

City of New York. MEA# 336-03-M.

•

These dampers are qualified for installation in 1 hr. and 2 hr. rated masonry walls or floors

and 1 hr. and 2 hr. rated metal or wood stud drywall partitions.

Refer to the

UL Classification

Marking on the

Product

Driveshaft

Driveshaft