Page

" C o m p l e t e A i r C o n t r o l a n d D i s t r i b u t i o n S o l u t i o n s . "

w w w . n a i l o r. c o m

Calgary, Canada

Tel: 403-279-8619

Fax: 403-279-5035

Houston, Texas

Tel: 281-590-1172

Fax: 281-590-3086

Toronto, Canada

Tel: 416-744-3300

Fax: 416-744-3360

Las Vegas, Nevada

Tel: 702-648-5400

Fax: 702-638-0400

" C o m p l e t e A i r C o n t r o l a n d D i s t r i b u t i o n S o l u t i o n s . "

Page 2.095

3/16 IOM-MBFDIMP

SPARE PARTS LIST

PART NUMBER

Fusible Links: Model 1200, 1250, 1290

165°F/74°C

B2-037

212°F/100°C

B2-038

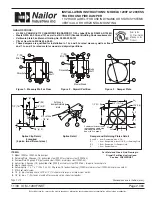

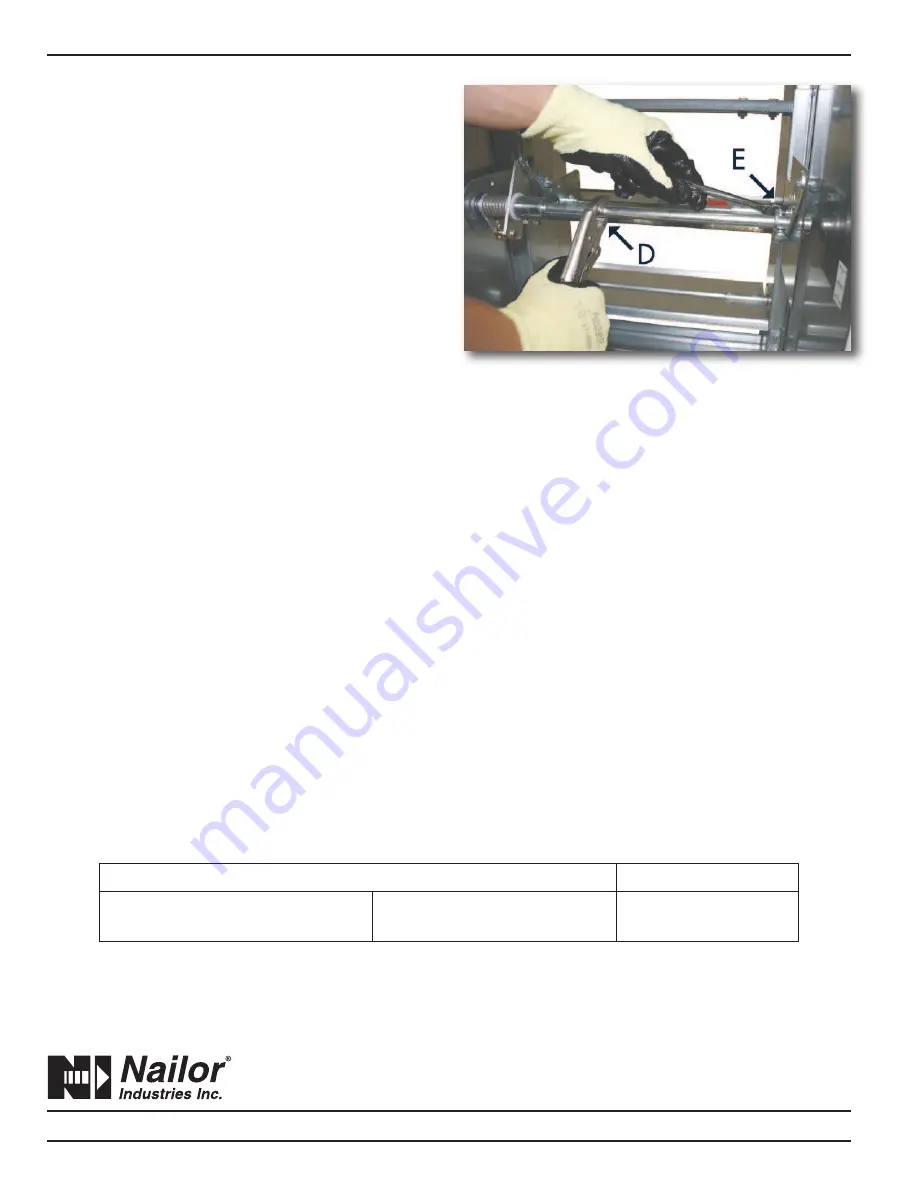

5. Manually open the damper to 100% full open position

(D)

. See Detail 3.

6. Tighten the bolt on the crank arm

(E)

. See Detail 3.

Reopening spring assisted fire dampers may be

extremely difficult and in some cases, impossible.

If it

is determined that the damper is impossible or impractical

to test or reopen, a thorough examination of the blade path

is required to ensure that nothing will prevent the damper

from closing. Common obstructions include: racked

damper frames, retaining angle installation screws,

construction debris and contaminants.

Detail 3

Page 2 of 2

Periodic Inspection, Testing and Maintenance

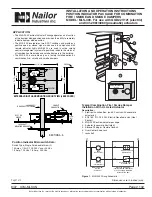

Consult your local building code to verify whether there is

a required maintenance and testing schedule. Most local

jurisdictions reference NFPA 80 for Fire Dampers.

Per NFPA 80, each damper should be inspected 1 year

after installation and then every 4 years, except for

hospitals, where the frequency is every 6 years.

1. Remove any obstructions, dirt, rust, corrosion, or other

observed conditions that could impede proper damper

operation. Clean damper blades and other moving parts if

necessary. Use of a mild detergent or solvents is

recommended for any cleaning required.

2. Check closure springs. If damaged or defective, repair

or replace.

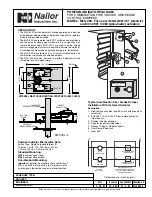

3. Linkage and jackshaft bearing brackets should be

lubricated with a dry lubricant (such as T.F.E. Dry Lube).

Never use a regular lubricating oil on dampers, as it will

attract dirt and grit. Blade linkage is concealed in the side

jamb out of the airstream and is maintenance free.

Bearings are self-lubricating oilite bronze (or stainless steel

for -SS models).

4. If firing of the fusible link is not required by local code,

cycle damper with its quadrant handle to verify that it fully

opens and closes. HVAC fans should be shut down. Care

should be exercised to ensure that such tests are

performed safely and do not cause system damage.

5. All inspections and testing shall be documented

indicating the location of the damper, date of inspection,

name of inspector, deficiencies detected, and how

deficiencies were corrected.

Receiving, Storage, Preparation

Upon delivery, inspect shipping containers and contents

closely. Note any damages on freight carrier’s delivery

receipt.

Store dampers in a cool, dry and safe location in an orderly

manner away from construction site, warehouse traffic,

other materials, etc. Cover with plastic sheeting to protect

from excessive moisture, dirt and debris.

Inspect dampers prior to installation. Dampers must be

cleaned per procedures outlined in this document prior to

installation if dirt, rust or corrosion is observed.