Nailor Industries Inc. reserves the right to change any information concerning product or specification without notice or obligation.

Page 2.102

8/07

IOM-MLS3N

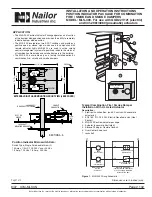

INSTALLATION AND OPERATION INSTRUCTIONS

POSITION INDICATOR PACKAGE FOR COMBINATION

FIRE / SMOKE AND SMOKE DAMPERS

MODEL: MLS-300. For use with GGD221/121 (electric)

and 331-2961/3060 (pneumatic) actuators

APPLICATION:

• The MLS-300 Position Indicator Package operates as a function

of the damper blade position and provides the ability to remotely

indicate damper blade position.

• The MLS-300 incorporates two SPDT switches and provides a

positive open or closed signal when used in conjunction with

remote indicator lights. MLS-300’s are used in active smoke

control management systems to positively indicate the status of

all combination fire/smoke and smoke dampers in the building.

• The MLS-300 is available only as a factory installed option on

combination fire / smoke and smoke dampers.

Position Indicator Microswitch Data:

Switch Type: Single Pole double throw (2)

15 Amps, 1/3 HP, 125, 250 Vac or 24 Vdc.

1/2 Amp, 125 Vdc. 1/4 Amp, 250 Vdc.

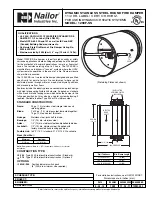

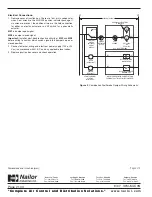

EXTERNAL RIGHT HAND MOUNTING: FRONT VIEW (LESS COVER)

COVER

A

A

2 7/8" (73)

3" (76)

4 1/8" (105)

MS-2

MS-1

BLUE

YELLOW

SECTION A - A

JACKSHAFT /

DRIVESHAFT EXTENSION

CONDUIT

CONNECTION

DUCT OR

SLEEVE

13/16"

(21)

JACKSHAFT

MOUNTING BRACKET

1

6

7

5

4

3

2

3

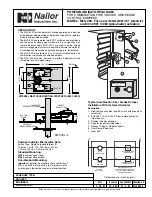

NAILOR INDUSTRIES INC.

MLS-300

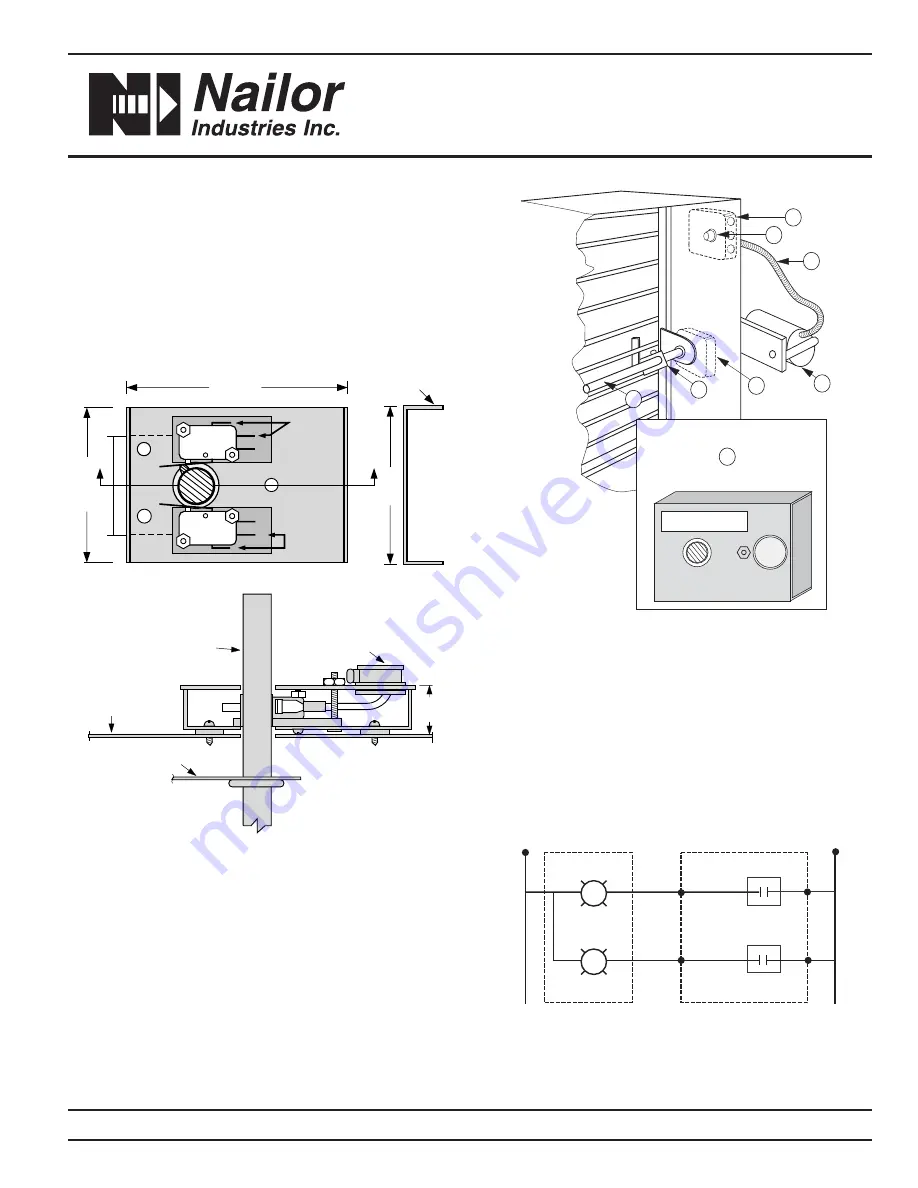

L2

L1

CLOSED

(YELLOW LIGHT)

OPEN

(GREEN LIGHT)

MS2 DAMPER CLOSED

MICROSWITCH

BLU

BLU

YEL

YEL

MS1 DAMPER OPEN

MICROSWITCH

REMOTE CONTROL

STATION

(BY OTHERS)

MOUNTED ON DAMPER

(FACTORY WIRING TERMINATES

AT SPLICE POINTS INDICATED

INSIDE SWITCH BOX)

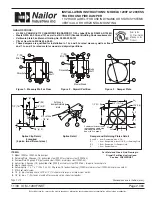

Typical Combination Fire / Smoke Damper

Installation With UL Listed Actuator

Description:

1. Electrical Junction Box. [and EP switch with pneumatic

actuator(s)]

2. ERL 165, 212, 250, 350 Electric Resettable Link (Heat

Sensor)

3. MLS-300 Position indicator package

4. Actuator (pneumatic illustrated).

5. Silicone Tubing or Flexible Conduit

6. Over-Center Knee Lock

7. Jackshaft

Figure 1.

MLS-300 Wiring Schematic.

Dimensions are in inches (mm).

Page 1 of 2