SCHEDULE TYPE:

PROJECT:

ENGINEER:

CONTRACTOR:

Nailor Industries Inc. reserves the right to change any information concerning product or pricing without notice.

DATE

B SERIES

SUPERSEDES DRAWING NO.

6 - 17 - 20

3000

4 - 30 - 20

P30RE-1

Page 2 of 2.

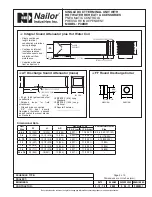

Dimensions are in inches (mm).

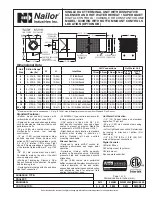

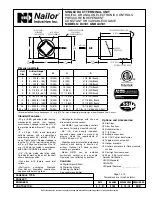

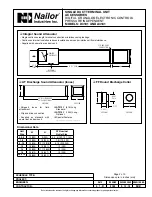

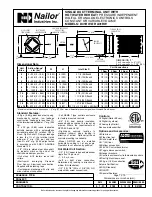

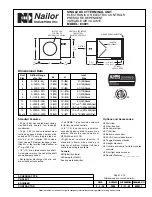

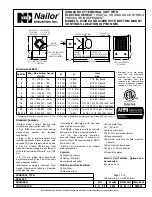

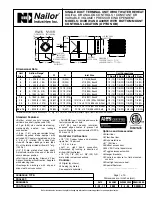

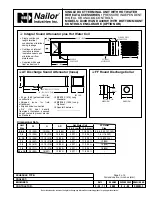

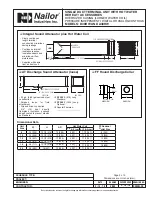

SINGLE DUCT TERMINAL UNIT WITH

ELECTRIC REHEAT

PNEUMATIC CONTROLS • PRESSURE INDEPENDENT

MODEL: P30RE

Nailor manufactures its own electric heating coils. They have

been specifically designed and tested for use with variable air

volume single duct terminal units.

All terminals with electric heat have been tested and ETL

listed as an assembly, eliminating the need to mount coils a

minimum of 36" (914) downstream or having to ship a bulky

length of ductwork when coils are to be supplied mounted on

the terminal.

Nailor electric coils are factory mounted as an integral part

of the terminal unit in an insulated extended plenum section.

Total length of the casing including heater terminal is only

31" (787), providing a compact, easy to handle unit. Freight

costs are therefore also reduced. The unique inclined opposed

blade damper design provides improved and more even airflow

over the coil elements compared with round butterfly damper

designs, which helps to minimize air stratification, avoid

nuisance tripping of the thermal cut-outs and maximize heat

pick-up.

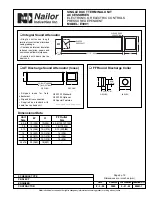

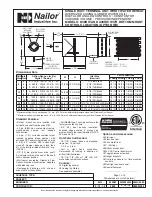

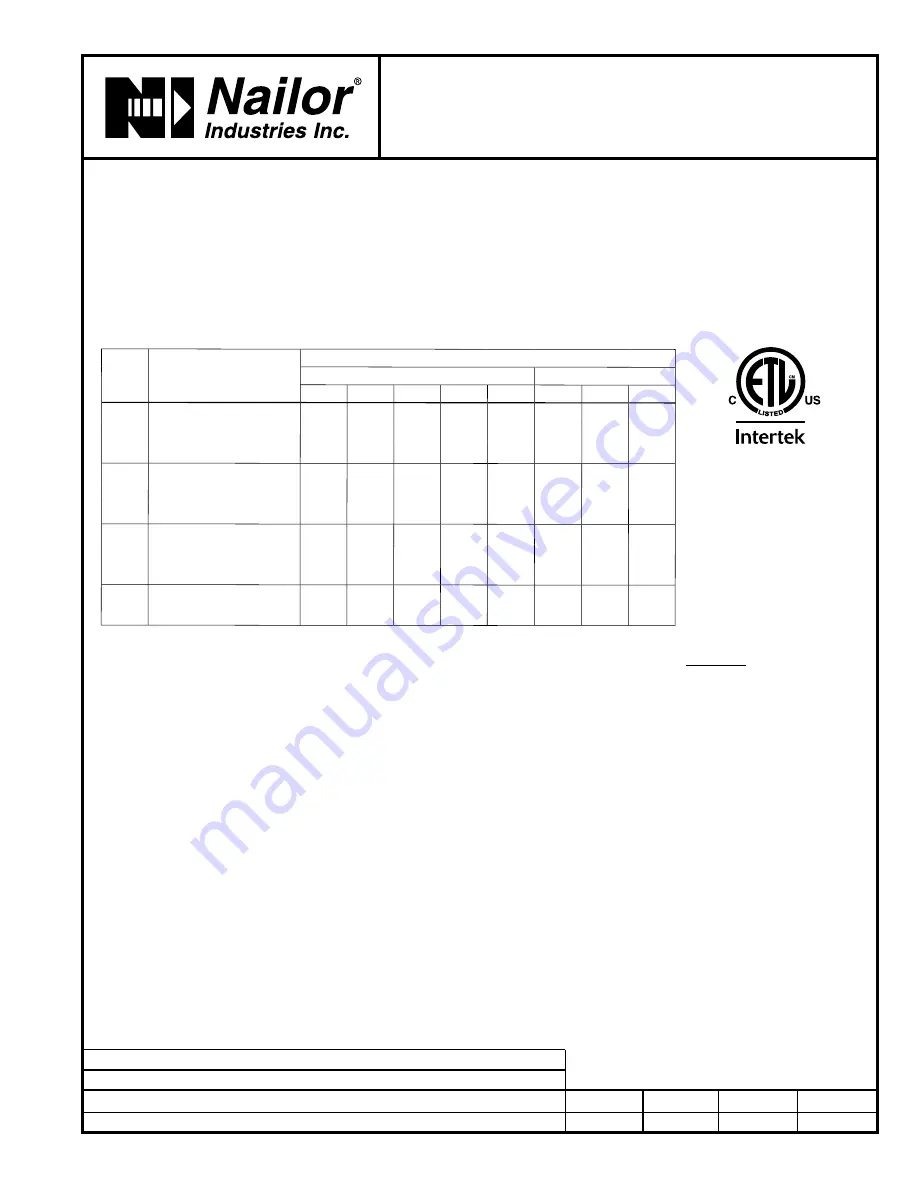

Selection Guidelines:

The table above provides a general guideline as to the

voltages and maximum kilowatts available for each terminal

unit size. Up to three stages of heat are available. A minimum

of 0.5 kW/stage is required.

For optimum diffuser performance and maximum thermal

comfort, ASHRAE recommends that discharge temperatures

do not exceed 15°F (8°C) above room set point, as stratification

and short circuiting may occur. ASHRAE Standard 62.1 limits

discharge temperatures to 90°F (32°C) or increasing the

ventilation rate when heating from the ceiling. Never select kW

to exceed a discharge temperatures of 120°F (49°C).

∆

T (Air Temp. Rise,

°

F) = kW x 3160

cfm

The coils ranges listed are restricted to a maximum of 48

amps and do not require circuit fusing to meet NEC code

requirements. A minimum of .1" w.g. (25 Pa) of downstream

static pressure is required to ensure proper operation of the

heater. To avoid possible nuisance tripping of the thermal

cutouts due to insufficient airflow, a minimum airflow of 70 cfm

(33 l/s) per kilowatt must be maintained. Check that desired

minimum airflow is within recommended operating range.

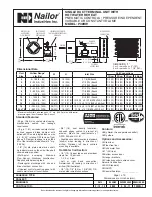

Standard Features:

• Primary auto-reset high limit thermal

cut-out (one per coil in control circuit).

• Secondary manual reset high limit

thermal cut-outs (one per element).

• Positive pressure air proving switch.

• Class A 80/20 Ni/Cr wire.

• PE Switch per stage. Back-up

contactors as required.

• Line terminal block.

• High performance arrowhead insulators.

• ETL Listed as an assembly.

• Hinged door control enclosure.

• Slip and drive discharge connection.

Voltage:

Single phase, 60 Hz.

q

120V

q

208V

q

240V

q

277V

q

347V

Three phase, 60 Hz.

q

208V

q

480V

q

600V

q

_____________________ .

Coil Options and Accessories:

q

Toggle type disconnect switch.

q

Door interlock disconnect switch.

q

Mercury contactors.

q

Power circuit fusing.

q

Dust tight construction.

q

Special Features:

__________________________ .

Tested and approved

to the following

standards:

ANSI/UL

1996, 1st. ed.

CSA C22.2

No. 155-M1986.

*

Minimum airflow must be the

greater of the air volume listed

or 70 cfm per kilowatt (33 L/s/

kW)

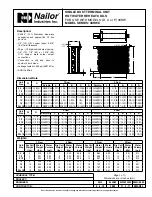

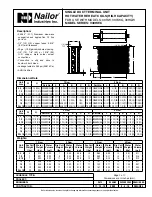

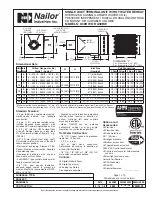

Electric Coil Limitations

Unit

Size

Heating Range*

cfm (l/s)

Maximum kW

Single Phase

Three Phase

120V

208V

240V

277V

347V

208V

480V

600V

4

30 – 180 (14 – 85)

3.0

3.0

3.0

3.0

3.0

3.0

3.0

3.0

5

55 – 325 (26 – 153)

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

6

80 – 450 (38 – 212)

5.5

7.5

7.5

7.5

7.5

7.5

7.5

7.5

7

115 – 650 (54 – 307)

5.5

9.5

9.5

9.5

9.5

9.5

9.5

9.5

8

155 – 900 (73 – 425)

5.5

9.5

11.0

13.0

13.0

13.0

13.0

13.0

9

200 – 1150 (94 – 543)

5.5

9.5

11.0

13.0

16.0

16.0

16.0

16.0

10

260 – 1500 (123 – 708)

5.5

9.5

11.0

13.0

16.5

17.0

21.0

21.0

12

355 – 2050 (168 – 967)

5.5

9.5

11.0

13.0

16.5

17.0

30.0

30.0

14

440 – 2550 (208 – 1203)

5.5

9.5

11.0

13.0

16.5

17.0

31.0

38.5

16

525 – 3040 (248 – 1435)

5.5

9.5

11.0

13.0

16.5

17.0

31.0

38.5

24 x 16

1180 – 6800 (557 – 3209)

5.5

9.5

11.0

13.0

16.5

17.0

31.0

38.5