Nailor Industries Inc. reserves the right to change any information concerning product or pricing without notice.

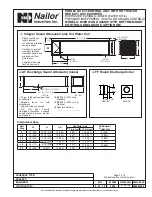

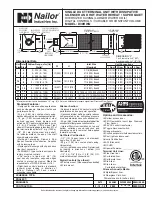

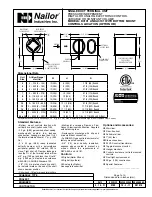

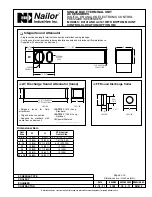

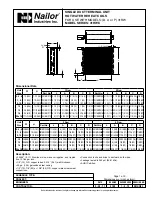

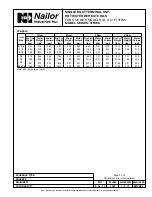

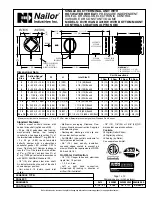

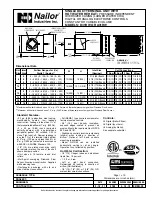

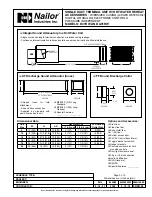

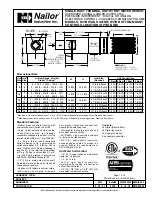

Dimensions are in inches (mm)

SCHEDULE TYPE:

PROJECT:

ENGINEER:

CONTRACTOR:

DATE

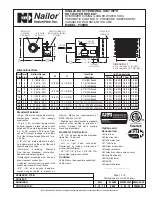

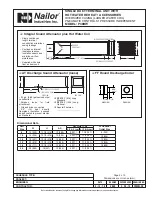

B SERIES

SUPERSEDES DRAWING NO.

3 - 24 - 21

VAV.ACC.

8 - 19 - 16

VAV-FDD

TERMINAL UNITS

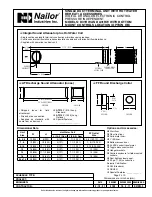

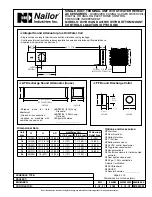

LINER OPTIONS

TYPE: FIBERGLASS DUAL DENSITY INSULATION

DESCRIPTION

Tuf-Skin dual-density fiber glass blankets are the most widely-used insulation for HVAC equipment applications. The

combination of high-density skin and low-density core provides high acoustical values in the high and low frequency

ranges normally encountered in HVAC equipment.

Application.

Tuf-Skin provides effective thermal and acoustical control in air conditioning and heating equipment.

Advantage.

The porosity and inherent structure of the flame-attenuated glass fiber blankets are highly effective in

reducing thermal transfer.

Tuf-Skin readily withstand damage from mechanical abrasion during assembly and from air erosion in service.

INSULATION CHARACTERISTICS

Material:

Dual density fiberglass, surface treated to prevent erosion

Thickness:

3/4" (19), 1" (25)

Density:

4.0 lb/cu.ft. (64 kg/m

3

) skin, 1.5 lb/cu.ft. (24 kg/m

3

) core

Thermal Conductance: 3/4" (19) - 0.36 BTU / hr-ft

2

-

°

F @ 75

°

F (2.04 W / m

2

-

°

C @ 24

°

C)

1" (25) - 0.26 BTU / hr-ft

2

-

°

F @ 75

°

F (1.47 W / m

2

-

°

C @ 24

°

C)

Thermal Resistance:

3/4" (19) - 2.8 hr-ft

2

-

°

F / BTU (0.49 m

2

-

°

C / W)

(Effective R-Value)

1" (25) - 3.8 hr-ft

2

-

°

F / BTU (0.68 m

2

-

°

C / W)

Flame Spread:

25

Smoke Density:

50

MAXIMUM AIR VELOCITY

3,600 FPM (1,097 mpm). Tested at two and one-half times (9,000 fpm) (2,743 mpm) the maximum recommended

service velocity. Meets the erosion requirements of UL 181.

STANDARD AND CODE COMPLIANCE

• ASTM E84 and UL 723 and CAN/ULC S102-M88 Flame/Smoke (25/50)

• NFPA 90A and 90B