Nailor Industries Inc. reserves the right to change any information concerning product or pricing without notice.

SCHEDULE TYPE:

PROJECT:

ENGINEER:

CONTRACTOR:

Page 1 of 2.

Dimensions are in inches (mm).

DATE

B SERIES

SUPERSEDES DRAWING NO.

6 - 17 - 20

3000

3 - 13 - 18

D30HQE

SINGLE DUCT TERMINAL UNIT WITH

ELECTRIC REHEAT AND DISSIPATIVE SILENCER

HOSPITAL GRADE • SUPER QUIET

DIGITAL CONTROLS • CONSTANT OR VARIABLE VOLUME

MODEL: D30HQE

Standard Features:

*

Minimum flows are based upon

0.02" w.g. (5 Pa) differential

pressure from flow sensor. The

maximum flow rate represents

the diamond flow sensor's

differential pressure reading at

1" w.g. (250 Pa).

• Designed for hospital and other critical

environment applications where IAQ is a

concern.

• 22 ga. (0.86) zinc coated steel casing,

mechanically sealed, low leakage

construction.

• 16 ga. (1.61) corrosion-resistant steel

inclined opposed blade damper with

extruded PVC seals (single blade on size

4, 5, 6). 45

°

rotation, CW to close. Tight

close-off. Damper leakage is less than

2% of the terminal rated airflow at 3" w.g.

(750 Pa).

• 1/2" (13) dia. plated steel drive shaft.

An indicator mark on the end of the shaft

shows damper position.

• Multi-point averaging Diamond Flow

Sensor. Aluminum construction. Supplied

with balancing tees.

• Rectangular discharge with slip and

drive cleat duct connection.

• Full NEMA 1 type controls enclosure for

factory mounted controls.

• VAV section is lined with 13/16" (21),

thick, 4 lb. density Seri-Liner insulation.

Fiberglass with a reinforced aluminum

FSK facing. Meets the requirements of

NFPA 90A, UL 181 and ASTM C 655.

"Notch and tuck" fabrication and full

seam length steel Z-strip construction.

• Electric Coil is mounted in an integral

silencer section.

• 24 VAC Control transformer.

• Right-hand controls location is standard

(shown) when looking in direction of

airflow. Optional left hand controls

mounting is available.

Silencer Section:

• Designed to mate with VAV section for

optimum performance and super quiet

operation.

• Optimized internal baffle geometry

reduces self-generated noise, minimizes

pressure drop and maximizes acoustic

attenuation.

• 22 ga. (0.86) coated steel perforated

baffles encapsulate fiberglass acoustic

media. Mylar lining with acoustical spacer

isolates material from airstream.

• Internal Steri-Liner insulation on top

and bottom optimizes sound reduction

and eliminates need for externally field

applied thermal duct wrap.

Digital Controls:

q

Nailor EZvav.

q

Factory mount (by others).

q

Field mount.

See separate submittal.

Options and Accessories:

q

Bottom access door.

q

FMI Removable insert type Diamond

Flow Sensor.

q

Toggle disconnect switch.

q

Hanger brackets.

q

Controls enclosure for field mounted

controls.

q

Dust tight enclosure seal.

q

20 ga. (1.00) construction.

Seismic Certification:

q

SSI (Standard).

q

OSHPD.

q

Special Features: ______________ .

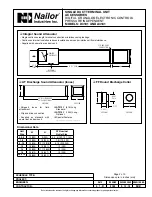

Electric Coil Features, Options and

Accessories:

See page 2 of 2.

*

Maximum airflow limit is based upon 1.5" w.g. (373 Pa) max. differential pressure signal from Diamond Flow Sensor.

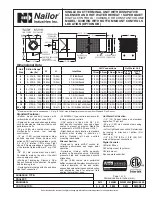

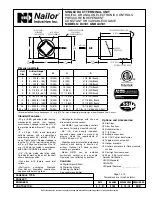

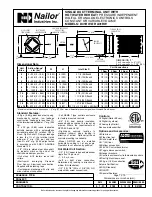

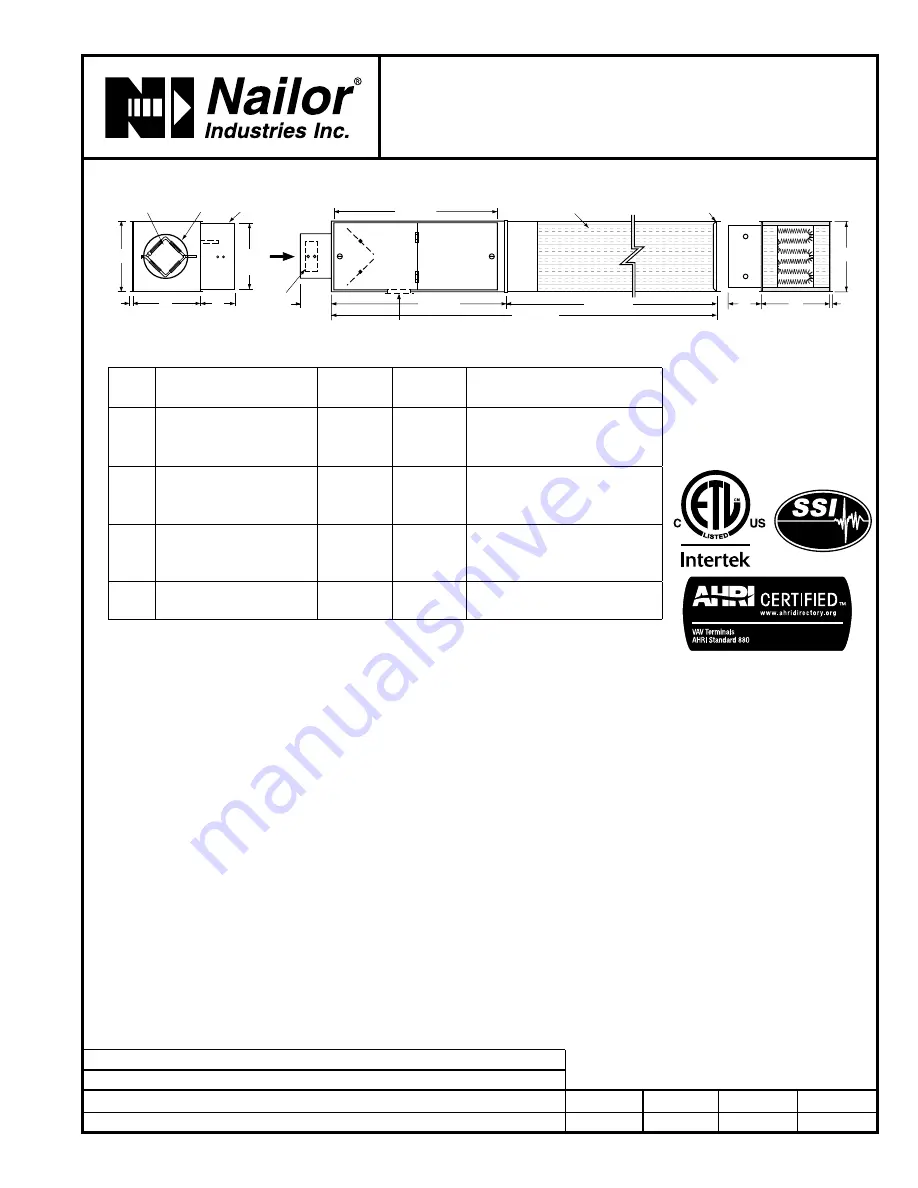

Unit

Size

Min.– Max. Airflow Range*

cfm (I/s)

W

H

Inlet

Size

4

25 – 225 (12 – 106)

10 (254)

10 (254)

3 7/8 (98) Round

5

45 – 400 (21 – 189)

10 (254)

10 (254)

4 7/8 (124) Round

6

65 – 550 (31 – 260)

10 (254)

10 (254)

5 7/8 (149) Round

7

95 – 800 (45 – 378)

12 (305)

12 1/2 (318)

6 7/8 (175) Round

8

125 – 1100 (59 – 519)

12 (305)

12 1/2 (318)

7 7/8 (200) Round

9

165 – 1400 (78 – 661)

14 (356)

12 1/2 (318)

8 7/8 (225) Round

10

215 – 1840 (101 – 868)

14 (356)

12 1/2 (318)

9 7/8 (251) Round

12

290 – 2500 (137 – 1180)

18 (457)

12 1/2 (318) 12 15/16 x 9 13/16 (329 x 249) Oval

14

360 – 3125 (170 – 1475)

24 (610)

12 1/2 (318) 16 1/16 x 9 13/16 (408 x 249) Oval

16

430 – 3725 (203 – 1758)

28 (711)

12 1/2 (318) 19 3/16 x 9 13/16 (487 x 249) Oval

24 x 16

960 – 8330 (453 – 3931)

38 (965)

18 (457)

23 7/8 x 15 7/8 (606 x 403) Rect.

Dimensional Data

Listed

5 1/2"

(140)

29" (737)

31" (787)

W

1/2"

(13)

H

OPTIONAL

ACCESS DOOR

W

H

48" (1219)

79" (2007)

6"

(152)

11 3/4"

(298)

1/2"

(13)

6"

(152)

CONTROLS ENCLOSURE

FOR FACTORY

MOUNTED

CONTROLS

OPTIONAL

(FMI)

REMOVABLE

FLOW SENSOR

RECTANGULAR DISSIPATIVE

MYLAR LINED SILENCER

SLIP AND DRIVE

CONNECTION

AIRFLOW

INLET: ROUND,

FLAT OVAL OR

RECTANGULAR

PRIMARY

AIR

VALVE

CONTROLS

ENCLOSURE

ELECTRIC COIL

CONTROLS

ENCLOSURE

(HINGED

ACCESS DOOR)

MULTI-POINT

AVERAGING

FLOW

SENSOR