95

21

. DISPOSAL OF THE CONTROLLER

When disposal of a CONTROLLER is necessary, follow the instructions from your local government agency for

proper disposal of industrial components.

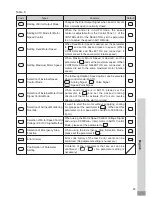

Trouble

Cause

Inspection / Corrective Active

Tool slippage.

Collet or collet nut are not correctly

installed.

Check and clean the collet and collet nut.

Reinstall the collet and collet nut.

The collet and the collet nut are worn.

Replace the collet and collet nut.

High run-out.

The cutting tool is bent.

Change the cutting tool.

Collet nut is not correctly installed.

Secure the collet and the collet nut

correctly.

The collet and the collet nut are worn.

Replace the collet and the collet nut.

Inside of the spindle is worn.

Replace the spindle shaft.

(Return to NAKANISHI dealer service.)

Contaminants inside the collet and the

collet nut or the spindle.

Clean the collet, collet nut and the inside

of the taper and spindle.

The spindle ball bearings have been

damaged.

Replace the ball bearings.

(Return to NAKANISHI dealer service.)