①

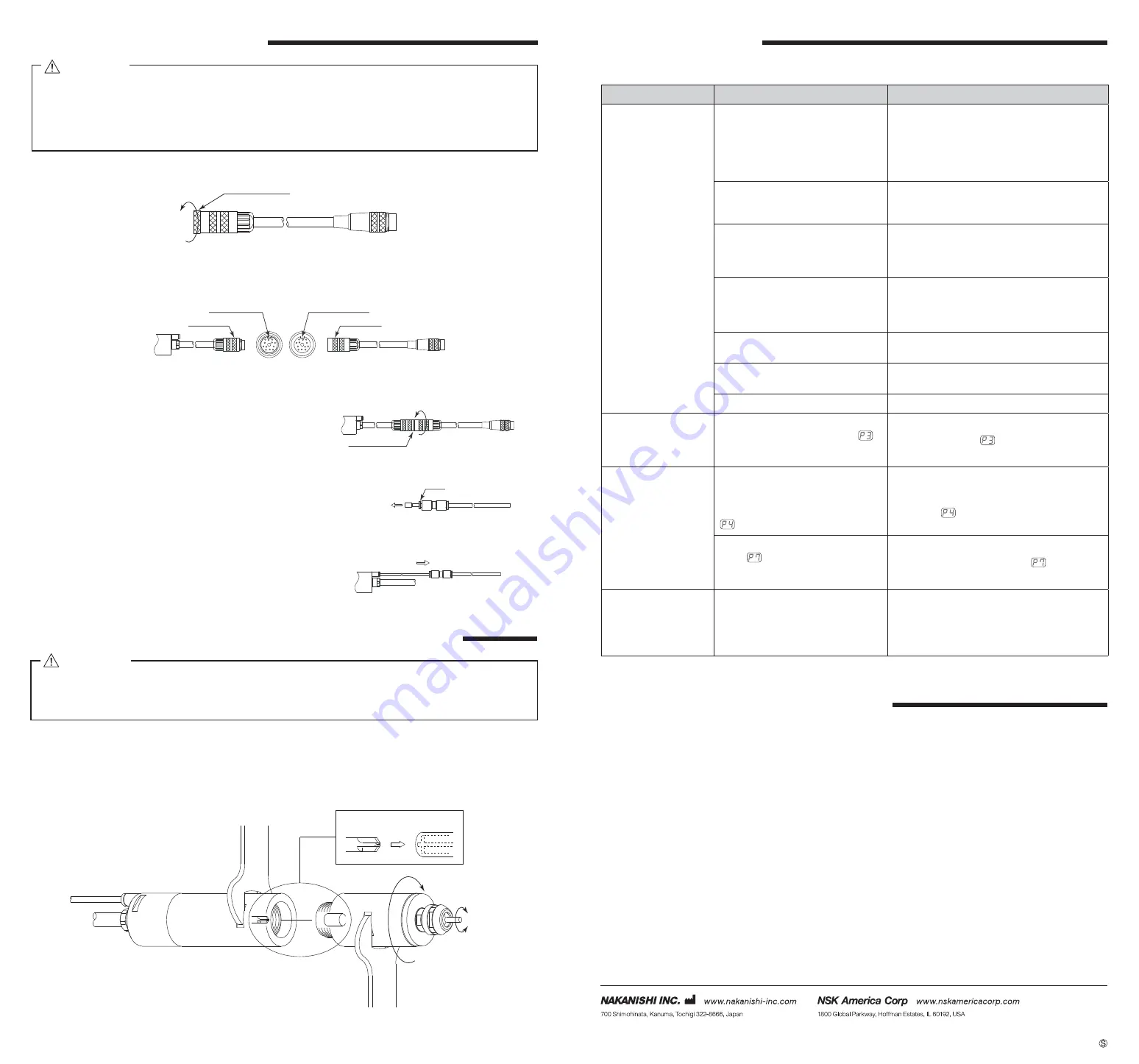

Remove the Protective Cover of the Motor Cord.

4

. CONNECTION OF MOTOR CORD

Protective Cover

Take Out

Fig. 4

②

Carefully insert the alignment pin into the alignment hole and push straight into the Connector of the Motor

Cord.

Alignment Hole

Alignment Pin

Connector

Connector

Motor side

Motor Cord side

Fig. 5

③

Tighten the Connector Nut with clockwise.

Fig. 6

④

Remove the protective air inlet Quick Disconnect Cover.

Push

Take Out

Fig. 7

⑤

Insert the provided air hose.

Insert

Fig. 8

CAUTION

・

Before connecting to the Motor Cord to the Motor and CONTROLLER, verify the Main Power

Switch in the CONTROLLER is turned OFF. If the Main Power Switch on the CONTROLLER is ON

while connecting the Motor Cord, damage to the CONTROLLER is possible.

・

Install the protective cover (Protective Cover etc.) to prevent damage or contamination to the

Motor Cord Plug when not in use.

Trouble

Cause

Inspection / Corrective Action

Motor does not run.

Power is not supplied.

・

Make sure to turn ON the Main Power Switch

on the front of the CONTROLLER.

・

Insert the Power Cord Plug correctly into the

Main Power Inlet with Power Supply Fuses of

the CONTROLLER.

・

Check if a fuse is blown.

Motor Cord Plug is not connected

to the Motor, CONTROLLER or

SELECTOR.

Connect the Motor Cord Plug correctly to the

Motor and CONTROLLER.

Control Button (CTRL) is set to

Manual mode but trying to start with

an External Command Signal through

Input / Output Connector A.

Start with the Start / Stop Button (START/

STOP), or set the Control Button (CTLR) on the

Control Panel to Auto mode.

Control Button (CTRL) is set to Auto

mode but trying to manually start with

the Start Button (START/STOP) on

the Control Panel.

Start with an External Command Signal or

set the Control Button on the Control Panel to

Manual mode.

Emergency Stop Signal is OFF

(Open).

Emergency Stop Signal is ON (Closed).

An Error has occurred.

(Error LED is lit.)

Check and correct the source of the Error Code.

Low air pressure.

Adjust to the air pressure

0.25 – 0.3MPa.

Can not set the

increase or decrease

of the motor rotation

speed.

Motor Fixed Speed is set in the

parameter.

Release parameter

.

Can not set the motor

speed to its maximum

allowable speed.

Either trying to set the value, more

than the rotation speed of the

connected motor, or the upper limit of

the rotation speed is set by parameter

.

Set the Maximum Rotation Speed to not

less than desired Motor Rotation Speed by

parameter

.

Air Input Monitoring Override is set

in the

parameter to ON and the

motor's maximum speed has been

limited to

30,000 min

-

1

.

Check the setting of parameter

.

A blinking dot appears

on Digital Speed

Indicator. Cannot set

the desired rotation

speed.

Gear Ratio is set to a value other

than

"

1.0

"

.

Check the setting of Gear Ratio.

6

. TROUBLESHOOTING

If a problem or concern occur, please check the following items prior to consulting your dealer.

Refer to the spindle and the E3000 CONTROLLER Operation Manuals.

Transmission Clutch

Tighten

Turn

27

27

Fig. 9

Align the thread on the front end of the Brushless Motor and the rear of the spindle, and turn the spindle clockwise.

If the drive shaft of the Brushless Motor does not engage properly to the drive dog on the spindle, it may only

turn aprroximately two threads before stopping. DO NOT FORCE THEM TOGETHER. Loosen the spindle from

the Brushless Motor, rotate the spindle shaft by hand then re-try. The drive shaft and the drive dog must be fully

engaged. When fully engaged, secure the Brushless Motor and spindle using the provided 27mm wrench. (Fig. 9)

5

. CONNECTION OF THE BRUSHLESS MOTOR TO THE SPINDLE

Make sure your hands and all interlocking parts of the spindle and Brushless Motor are clean

before connecting the Brushless Motor to the spindle. This is critical to preventing contaminants

from entering the Brushless Motor or spindle.

CAUTION

7

. DISPOSAL OF THE BRUSHLESS MOTOR

When disposal of a Brushless Motor is necessary, follow the instructions from your local government agency for

proper disposal of industrial components.

2015.04.20 005

Tighten

Connector Nut