5

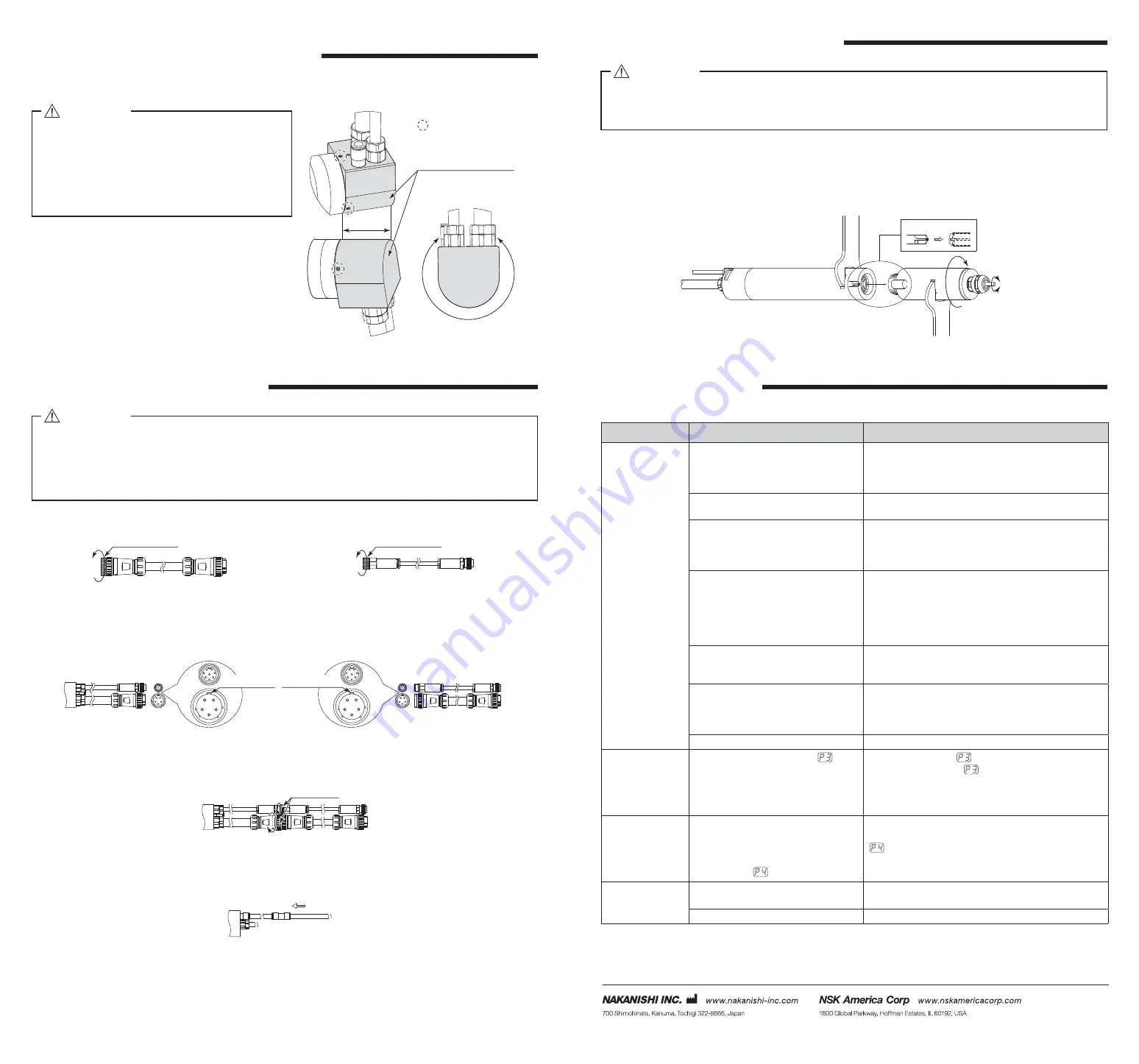

. CONNECTION OF MOTOR CORD

・

Before connecting to the Motor Cord to the Motor and CONTROLLER, verify the Main Power

Switch in the CONTROLLER is turned OFF. If the Main Power Switch on the CONTROLLER is

ON while connecting the Motor Cord, damage to the CONTROLLER is possible.

・

Install the protective cover (Protective Cover etc.) to prevent damage or contamination to the

Motor Cord Plug when not in use.

①

Remove the Protective Cover of the Motor Cord (Motor Power Line and Motor Signal Line).

Fig. 6

②

Carefully insert the Alignment Pin into the Alignment Hole and push straight into the Connector of the Motor

Cord.

Fig. 8

③

Tighten the Coupling Nut with clockwise.

Fig. 9

③

Insert the air hose of the Motor Cord Side to the air joint of the Motor Side.

Fig. 10

①

Loosen the Fastening Screw (3 locations) of the Motor

Cord Exit Housing.

②

Adjust the Motor Cord Exit Housing to the desired

position.

③

Re-tighten the Fastening Screws (3 locations) of the

Motor Cord Exit Housing.

4

. POSITION ADJUSTMENT OF THE MOTOR CORD EXIT HOUSING (BLUE

AREA) ON THE EM-

4020

A and EM-

4040

A

The Motor Cord Exit Housing (Blue Area) of the EM-4020A and EM-4040A can be adjusted by rotating to a desired

position.

Fig. 5

7

. TROUBLESHOOTING

Make sure your hands and all interlocking parts of the spindle and motor are clean before

connecting the motor to the spindle. This is critical in preventing contaminants from entering

the motor or spindle.

Align the threads on the front end of the motor and the rear end of the spindle, then rotate the spindle clockwise. If

the drive shaft of the motor does not engage the drive dog on the spindle, it will not be possible for the spindle to

rotate. DO NOT FORCE THIS CONNECTION. Turn the spindle back a few threads, rotate the collet cap or spindle

shaft slightly by hand until the drive shaft and the drive dog are fully engages. This may take several attempts.

Use the 36mm wrench that have been provided for the final tightening of the spindle to the motor.

Fig. 11

If a problem or concern occurs, please check the following prior to consulting your dealer.

Trouble

Cause

inspection / Corrective Action

Motor does not

run.

Power is not supplied.

・

Make sure to turn ON the Main Power Switch on

the rear of the CONTROLLER.

・

Connect the power cord correctly to the AC Power

Input Terminal Block of the CONTROLLER.

Motor Cord Plug is not connected to

the Motor and CONTROLLER.

Connect the Motor Cord plug correctly to the Motor

and CONTROLLER.

Control Button (CTRL) is set to

Manual mode but trying to start with

an External Command Signal through

Input / Output Connector A.

Start with the Start / Stop Button (START / STOP), or

set the Control Button (CTLR) on the Control Panel

to Auto mode.

Control Button (CTRL) is set to Auto

mode but trying to manually start with

the Start Button (START / STOP) on

the Control Panel.

Start with an External Command Signal or set the

Control Button on the Control Panel to Manual mode.

(When Start with an External Command Signal,

refer to " 13 - 1 (1) Details of External Input / Output

Connector A Signal Table 2 Pin No. 14 " section of

the E4000 CONTROLLER Operation Manual. )

When using the E4000 Safety Relay

Box, Emergency Stop Signal is OFF

(Open).

Emergency Stop Signal is ON (Closed).

An Error has occurred. (Error LED is

lit.)

Check the "Resetting System after Error Codes" of

the E4000 CONTROLLER Operation Manual. Error

will not be released until cause of the error has been

removed.

Low air pressure.

Adjust to the air pressure 0.2 – 0.35MPa.

Can not increase

or decrease the

speed of the

motor.

Motor Fixed Speed is set in

parameter. Turn this Parameter OFF

to allow rotational speed changes

Release parameter

.

(Refer to " 15 - 4

③

Setting Fixed Motor Speed

" section of the E4000 CONTROLLER Operation

Manual.)

Can not set the

motor speed to

its maximum

allowable speed.

Either the required speed value is

higher than the maximum rotation

speed of the motor, or the upper limit

of the rotational speed has been set

in parameter

.

Set the Maximum Rotation Speed to a value less

than the Motor Rotation Speed set in Parameter

.

Abnormal

vibration or noise

during rotation.

Cutting debris has contaminated the

ball bearing.

Replace the ball bearings.

(Return to NAKANISHI dealer service.)

Low air pressure.

Adjust to the air pressure 0.2 – 0.35MPa.

2015.07.20 002

九

CAUTION

Motor Cord Exit Housing (Blue Area) cannot

be rotated more than 360 degrees. If forcibly

rotated, the mechanical stop inside the Exit

Housing will break and cause the base of the

cord to kink, leading to internal damage of the

cord.

Motor Cord Exit Housing

(Blue Area)

:

Fastening Screw

(3 locations)

Rotating Part

Turns 360

゚

CAUTION

Protective Cover

Detach

Motor Power Line

Fig. 7

Protective Cover

Detach

Motor Signal Line

Motor Cord Side

Motor Side

Alignment Pin Alignment Hole

Tighten

Coupling Nut

Insert

6

. CCONNECTION TO THE SPINDLE

CAUTION

Tighten

Turn

Transmission Clutch

36

36

Refer to the E4000 CONTROLLER Operation Manual.