A. GROUNDING INSTRUCTIONS

q

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to

reduce the risk of electric shock. This tool is equipped with an electric cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged into a matching outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

w

Do not modify the plug provided - if it will not fit the outlet, have the proper outlet installed by a qualified electrician.

e

Improper connection of the equipment-grounding conductor can result in a risk of electric shock. The conductor

with insulation having an outer surface that is green with or without yellow stripes is the equipment-grounding

conductor. If repair or replacement of the electric cord or plug is necessary, do not connect the equipment-

grounding conductor to a live terminal.

r

Check with a qualified electrician or service personnel if the grounding instructions are not completely understood,

or if in doubt as to whether the tool is properly grounded.

t

Use only 3-wire extension cords that have 3-prong grounding plugs and 3-pole receptacles that accept the tool's plug.

S

Cautions for handling and operation...P.1

S

Component Names .........................P.3

S

Setting Up the Control Unit............P.4

S

Operating Procedures ....................P.5

S

Memory-Speed Function, FIXPEED ....P.6

S

Load Monitor LED ...........................P.6

S

Motor Protection Circuit ................P.6

S

Turn-On-Memory Function ...........P.6

S

Error Codes .....................................P.7

S

Fuse Replacement .........................P.7

S

Maintenance Mode ........................P.8

S

Motor and Attachment Operation ......P.9

S

Handpiece Stand ..........................P.11

S

Handpiece Holder ........................P.11

S

Specifications ...............................P.12

S

European EC Directive Conformation ....P.12

S

Troubleshooting ...........................P.13

S

Optional Motors and Handpieces .....P.14

2

1

Thank you for purchasing Emax Evolution. This is a high-precision, extremely high speed micromotor

rotary hand tool system. This system is designed for high-precision, small diameter deburring,

grinding and a wide variety of other applications.

Keep this Operation Manual near Emax Evolution system for any operators to refer to whenever

operating this system.

Please read this Operation Manual carefully prior to use.

y

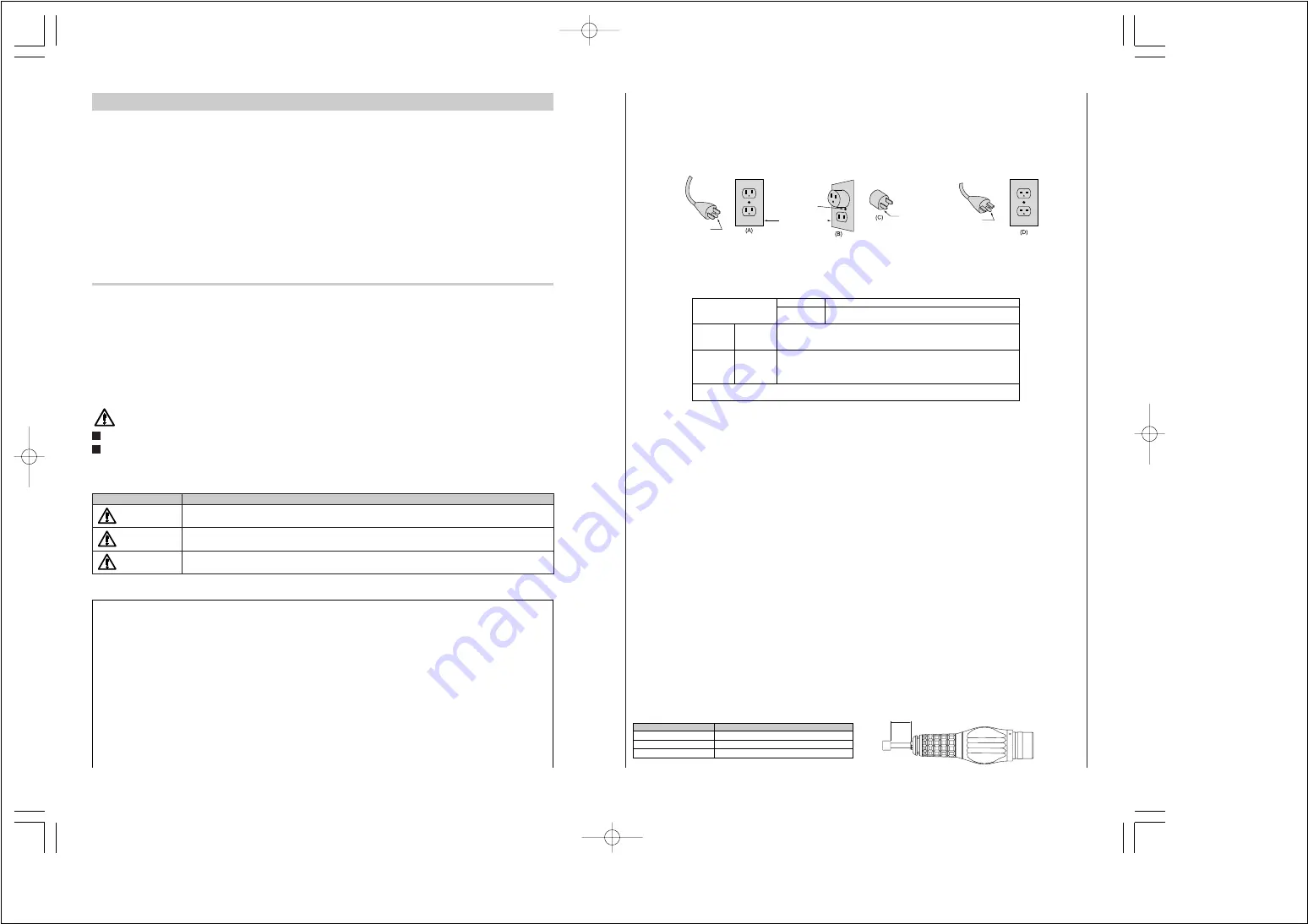

(120V) This tool is intended for use on a circuit that has an outlet that looks like the one illustrated in Sketch A in Figure

(below). The tool has a grounding plug that looks like the plug illustrated in Sketch A in figure (below). A temporary

adapter, which looks like the adapter illustrated in Sketches B and C, may be used to connect this plug to a 2-pole

receptacle as shown in Sketch B if a properly grounded outlet is not available. The temporary adapter should be used

only until a properly grounded outlet can be installed by a qualified electrician. The green-colored rigid ear, Iug, and the

like, extending from the adapter must be connected to a permanent ground such as a properly grounded outlet box.

Note : Adopter (Figure B) not for use in Canada.

u

USE PROPER EXTENSION CORD Make sure your extension cord is in good condition. When using an extension cord, be

sure to use one heavy enough to carry the current your product will draw. An undersized cord will cause a drop in line

voltage resulting in loss of power and overheating. Table (below) shows the correct size to use depending on cord length

and nameplate ampere rating. If in doubt, use the next heavier gauge. The smaller the gauge number, the heavier the cord.

q

Do not exceed the " Maximum Allowable Motor Rotation Speed " (Refer to "

S

Specifications ").

w

When sensing that the attachment and motor are overheated during operation, reduce the working force or the

motor rotation speed, or stop the operation until the attachment cools down before restarting.

e

Always wear cap, gloves, Iong sleeve shirt, safety glasses and hearing protection anytime this device is in use.

r

Do Not Touch the attachment or motor when the system is operating.

t

This is a high torque system and burs can grab on the workpiece. Always wear gloves to prevent injury anytime you

are using this system. Grinding and deburring produces lots of chips and other dust, keep work are clean and put

away items that can be damaged by chips, sand or other contaminants.

y

Check that the collet has been securely tightened prior to each use. Burs can fly loose from the chuck and injure operator or anyone nearby.

u

Avoid applying heavy hand pressure during operation; Iet the tool do the work. Heavy force can bend or break bur shanks

which can injure operator or anyone nearby. If the motor slows down noticeably during operation, you are applying too

much pressure; this type of operation will shorten motor, attachment and tool life and dramatically reduce productivity.

i

Do not use bent, broken, cracked or damaged tools, or tools with excessive runout. When using tools with a very

large head to shank diameter ratio sudden speed increases can bend or break shank. When using a new or large

tool, rotate it at low speed and increase speed gradually for safety.

o

Always operate tools within the tool manufacturer's recommended speed limits. Use of a tool outside of the manufacturer's

recommended speed limits could cause damage to the spindle and injury to the operator. A foot pedal can be used to vary speed.

!0

Do not hit or drop the attachment or motor because the shock can damage internal components. Always set the

control unit on a flat, hard, steady surface.

!1

If the control unit, motor or attachment emit smoke, burning plastic odor or any other unusual odor, please

immediately turn off the power switch, disconnect the power cord and send to NAKANISHI for service.

!2

Never attempt to operate this system, touch power cord or switch unit on or off, etc. with wet hands. Failure to

adhere to this warning can result in severe electric shock.

!3

Use only tools with shank diameter tolerance similar to the chuck I.D. tolerance.

!4

The motor has a nakanishi Smart switch which provides a click sensation. Be careful when operating the switch, because the motor is on/off.

!5

Do not exceed 13mm overhang for mounted grindstones. In case overhang must exceed 13mm reduce the motor

speed in accordance with Table 1 .

!6

Do not disassemble, modify or attempt to repair the control unit, motor, motor cord, attachment and foot pedal. Additional

damage internal components. Service must be performed by NSK NAKANISHI or an authorized service center.

Contents

Cautions for handling and operation

Read these cautions carefully and only use in the manner intended.

Safety instructions are intended to avoid potential hazards that could result in personal

injury or damage to the device. Safety instructions are classified as follows in accordance

with the seriousness of the risk.

WARNING

CAUTION

NOTICE

Class

Degree of Risk

A hazard that could result in bodily injury or damage to the device if the safety

instructions are not followed.

A hazard that could result in light or moderate bodily injury or damage to the device if

the safety instructions are not followed.

General information needed to operate the device safely.

B. OTHER WARNING INSTRUCTIONS

Grounding Method

Minimum gauge for cord

ADAPTER

METAL SCREW

COVER OF GROUND

OUTLET BOX

GROUNDING

MEANS

GROUNDING

PIN

GROUNDING

PIN

Volts

120V

240V

7.5m (25ft.) 15m (50ft.) 30m (100ft.) 45m (150ft.)

15m (50ft.) 30m (100ft.) 60m (200ft.) 90m (300ft.)

Ampere Rating

Total length of cord

More

Than

0

6

10

12

Not

More

Than

6

10

12

16

18

18

16

14

16

16

16

12

16

14

14

14

12

12

Not Recommended

Only the applicable parts ot the Table need to be included. For instance, a 120volt product need

include the 240-volt heading.

N : Max. operating speed at 13mm overhang.

Overhang (mm)

20

25

50

N x 0.5

N x 0.3

N x 0.1

Maximum Operating Speed min

-1

Table 1. Overhang versus Speed

13

EmaxEVO̲OM-K0572E̲e̲1511 15.12.1 10:28 PM ページ 1