11

14

. TROUBLESHOOTING

If a problem or concern occur, please check the following items prior to consulting your dealer.

15

. DISPOSAL OF THE SPINDLE

When disposal of a Spindle is necessary, follow the instructions from your local government agency for proper

disposal of industrial components.

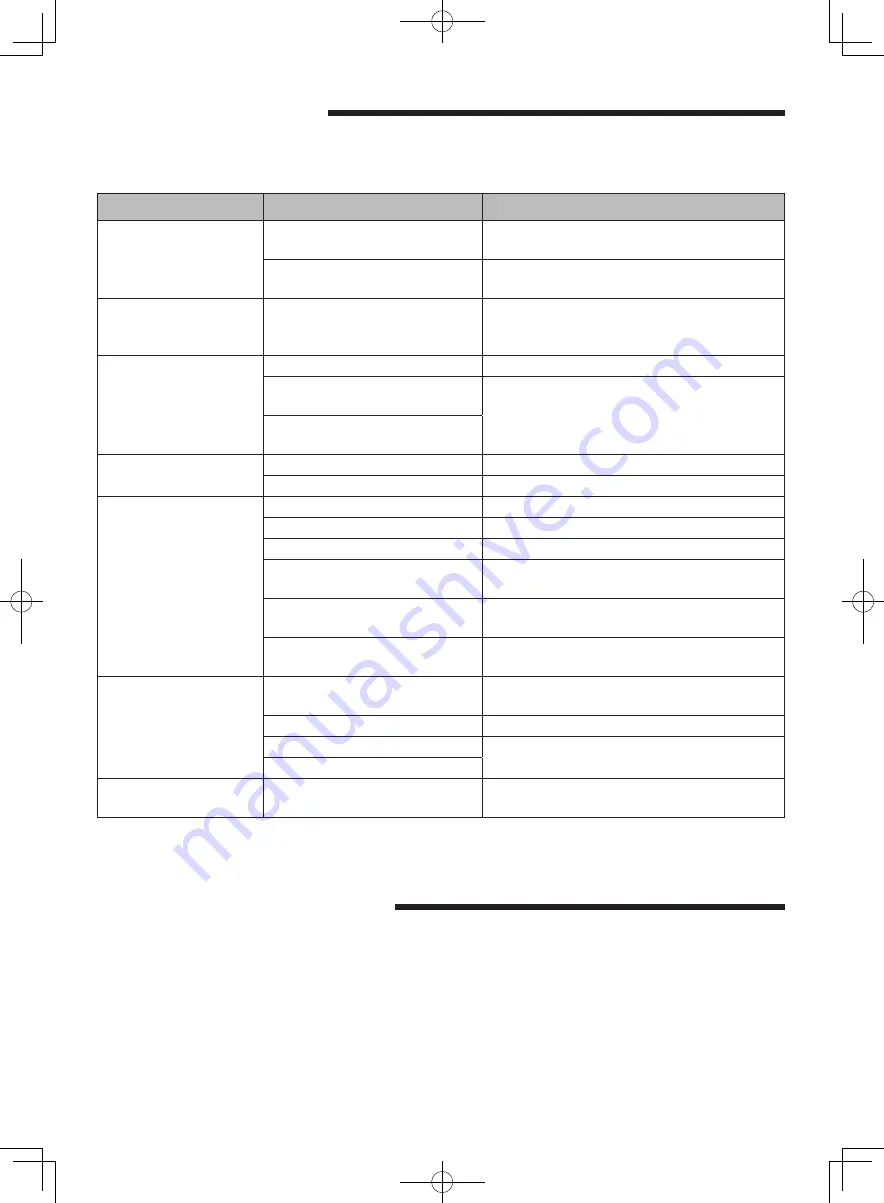

Trouble

Cause

Inspection/Corrective Action

Spindle does not rotate

or rotate smoothly.

The spindle ball bearings have

been damaged.

Replace the ball bearings.

(Return to NAKANISHI dealer service.)

The motor has been damaged.

Replace the motor.

(Return to NAKANISHI dealer service.)

Overheating during

rotation.

Cutting debris has contaminated

the ball bearings, and the ball

bearings are damaged.

Replace the ball bearings.

(Return to NAKANISHI dealer service.)

Abnormal vibration or

noise during rotation.

The tool shank is bent.

Replace the tool.

Cutting debris has contaminated

the ball bearing.

Replace the ball bearings.

(Return to NAKANISHI dealer service.)

The spindles ball bearings have

been damaged.

Tool slippage.

Collet is not correctly installed.

Check and clean the collet. Reinstall the collet.

The collet is worn.

Replace the collet.

High run-out.

The tool is bent.

Change the tool.

Collet is not correctly installed.

Secure the collet correctly.

The collet is worn.

Replace the collet.

Inside of the Spindle is worn.

Replace the Spindle shaft.

(Return to NAKANISHI dealer service.)

Contaminants inside the collet or

the Spindle.

Clean the collet and the inside of the taper and

Spindle.

The Spindle ball bearings have

been damaged.

Replace the ball bearings.

(Return to NAKANISHI dealer service.)

Check can not be opened

and closed.

Poor the air hose.

Check all threaded joints and re-tighten if

necessary.

The air hose has been damaged.

Replace the air hoses.

Low air pressure.

Check and adjusting the air circuit.

Error connection of the air circuit.

Power can not be

supplied.

The conductive component is

worn.

Replace the conductive component.

(Return to NAKANISHI dealer service.)

Refer to the brushless motor and the E3000 CONTROLLER Operation Manuals.

OM-KK0912EN000_NR33-6000ATC-ESD_200608_下版.indd 11

2020/06/05 16:47:57