7

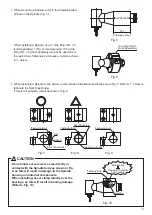

. INSTALLATION OF THE SPINDLE

WARNING

When installing a Spindle to a fixed base, make sure the fixed base is grounded in order to avoid

the risk of an electric shock.

CAUTION

・

When installing a Spindle, do not hit, drop or cause shock to the Spindle. This may cause

damage to internal components and result in malfunctions.

・

When mounting the Spindle, be sure to mounting within clamping area etched on the Spindle.

If the Spindle is installed incorrectly, this will cause and damage to the Spindle.

・

Cautions when tightening the securing bolt of the Split Type Holder

Do not over-tighten the bolt. This may cause damage to Spindle's precision.

Tighten the bolt until the Spindle body can not be turned by hand within the fixture.

Extreme tightening is not necessary or recommended.

Apply working force and check that the Spindle is tight before using.

4

Fig. 3

8

5

Spindle Shaft

7

5.5

Loosen

Tighten

Wrench 5.5mm

Tool

Collet Chuck

Wrench 8mm

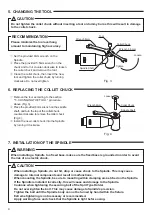

①

Set the provided 8mm wrench on the

Spindle.

②

Place the provided 5.5mm wrench on the

chuck and turn it counter-clockwise to loosen

the collet chuck and remove the tool.

③

Clean the collet chuck, then insert the new

tool and tighten the collet chuck by turning

clockwise. Do not overtighten.

Fig. 4

8

5

Loosen

Collet Chuck

Wrench 8mm

Spindle Shaft

①

Remove the tool according to the section

" 5. CHANGING THE TOOL " procedure

above (Fig. 3).

②

Place the provided 8mm wrench on the spindle

shaft, and turn the top of the collet chuck

counter-clockwise to remove the collet chuck

(Fig. 4).

③

Install the new collet chuck into the Spindle

by turning it clockwise.

RECOMMENDATION

Please minimize the tool overhang

amount to maintaining high accuracy.

5

. CHANGING THE TOOL

CAUTION

Do not tighten the collet chuck without inserting a tool or dummy bur as this will result in damage

to the collet chuck.

6

. REPLACING THE COLLET CHUCK