7

①

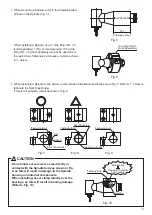

The proper surface speed for general grindstones is 10 - 30m / s.

②

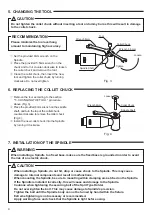

Do not exceed 13mm of overhang for mounted grindstones as shown in Fig. 12. If the overhang must exceed

13mm, reduce the motor speed in accordance with Table 2.

③

Dress the grindstone prior to use.

④

Do not use cutting tools with bent or broken shanks, cracks or excessive run-out.

⑤

For grinding, the maximum depth of cut should not exceed 0.01mm radially or axially. Reciprocate the tool

several times after each pass to eliminate tool pressure.

⑥

Always operate cutting tools within the allowable recommended speed of the cutting tools. Use of a cutting

tool outside of the allowable speed of the cutting tools could cause damage to the spindle and injury to the

operator.

⑦

Keep the cutting tool shank and collet chuck clean. If contaminants are left in the collet chuck or chuck nut,

excessive run-out will cause damage to the cutting tool and or Spindle.

⑧

Do not strike or disassemble the Spindle.

⑨

Please minimize the tool overhang amount to maintaining high accuracy. 13mm is the maximum amount of

overhang to maintain high accuracy and safety.

3.14 x Diameter (mm) x rotation speed (min

-1

) (rpm)

1,000 x 60

Surface Speed (m /s)

=

9

. CAUTIONS WHEN USING GRINDSTONES AND TOOLS

CAUTION

The maximum surface speed or rpm is always specified for a grindstone. Do not exceed the

maximum speed with reference to the calculating chart below. Always follow the grindstone

manufacturer's recommendations.

Fig. 12

13

Table

2. Overhang and Speed

Overhang (mm)

Max. Speed (min

-1

) (rpm)

20

N x 0.5

25

N x 0.3

50

N x 0.1

※

N = Max. Operating Speed with

13mm overhang.