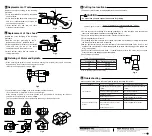

Replace the tools according to the following

procedure.

①Place the provided 7㎜ wrench on the spindle

shaft to fasten.

②Place the provided 5㎜ wrench on the chuck,

and turn it counterclockwise to loosen the

chuck. And pull out the tool.

③Insert another tool and turn the chuck

clockwise to fasten the tool.

5

Replace the chuck according to the following

procedure.

①Remove the tool according to the

5.

Replacement of Tools procedure above.

②Place the provided 7㎜ wrench on the spindle

shaft, and turn the top of the chuck

counterclockwise to remove the chuck.

③Attach another chuck into the spindle by

turning it clockwise.

6

7

Slit

Fastening Bolt

Fastening Bolt

Split Bushing

Bushing Split

Fastening Bolt

Trouble

Cause

Inspect/Corrective Action

Tool Slippage

Contaminants inside the chuck or the

spindle.

Chuck is not properly positioned.

Cutting tool is bent .

Ball bearing is worn out.

Use the bent tool.

Ground Particles stuck in the collet

chuck or spindle.

Ball bearing is worn out.

Clean the inside of the chuck and the

spindle.

Set the chuck properly.

Replace cutting tool.

Send to NAKANISHI for Repair.

Change the tool.

Send to NAKANISHI for Repair.

Noise or vibration during

rotation

Surface Speed (m/min)=

3.14 × Diameter(㎜) × rotation speed(min

−1

(rpm))

1,000

Overhang(㎜)

20

25

50

Max. Operating Speed(min

−1

)

N×0.5

N×0.3

N×0.1

Table 1.Overhang and Speed

N:Max. operating speed at 13㎜ overhang.

①The proper surface speed for vitrified grindstones is 600-1800m/min.

②Do not exceed 13㎜ overhang for mounted grindstones. In case overhang must exceed 13㎜

reduce the motor speed in accordance with

!

and Table 1.

③Do not use tools with bent or broken shanks, cracks or excessive runout.

④Dress the grindstone prior to use.

⑤For grinding the maximum depth of cut should not exceed 0.01㎜ radially or axially. Reciprocate

the tool several times after each in feed step.

⑥Always operate tools within the tool manufacturer,s recommended speed limits. Use of a tool

outside of the manufacturer,s recommended speed limits could cause damage to the spindle and

injury to the operator.

⑦Keep the tool shank and collet clean. If contaminants are left in the collet ,they can cause

excessive runout and damage the tool and spindle.

⑧Do not drop or hit spindle.

8

"

When trouble is found, please check the following prior to consulting your dealer.

# $%&&&'

!

"()*+,

!

9

-

5

.1

8

7

5

Loosen

Tighten

Wrench 5㎜

Wrench 7㎜

Chuck

Tool

Spindle

Wrench 7㎜

Chuck

Loosen

7

5

.1

13

'07.08.003

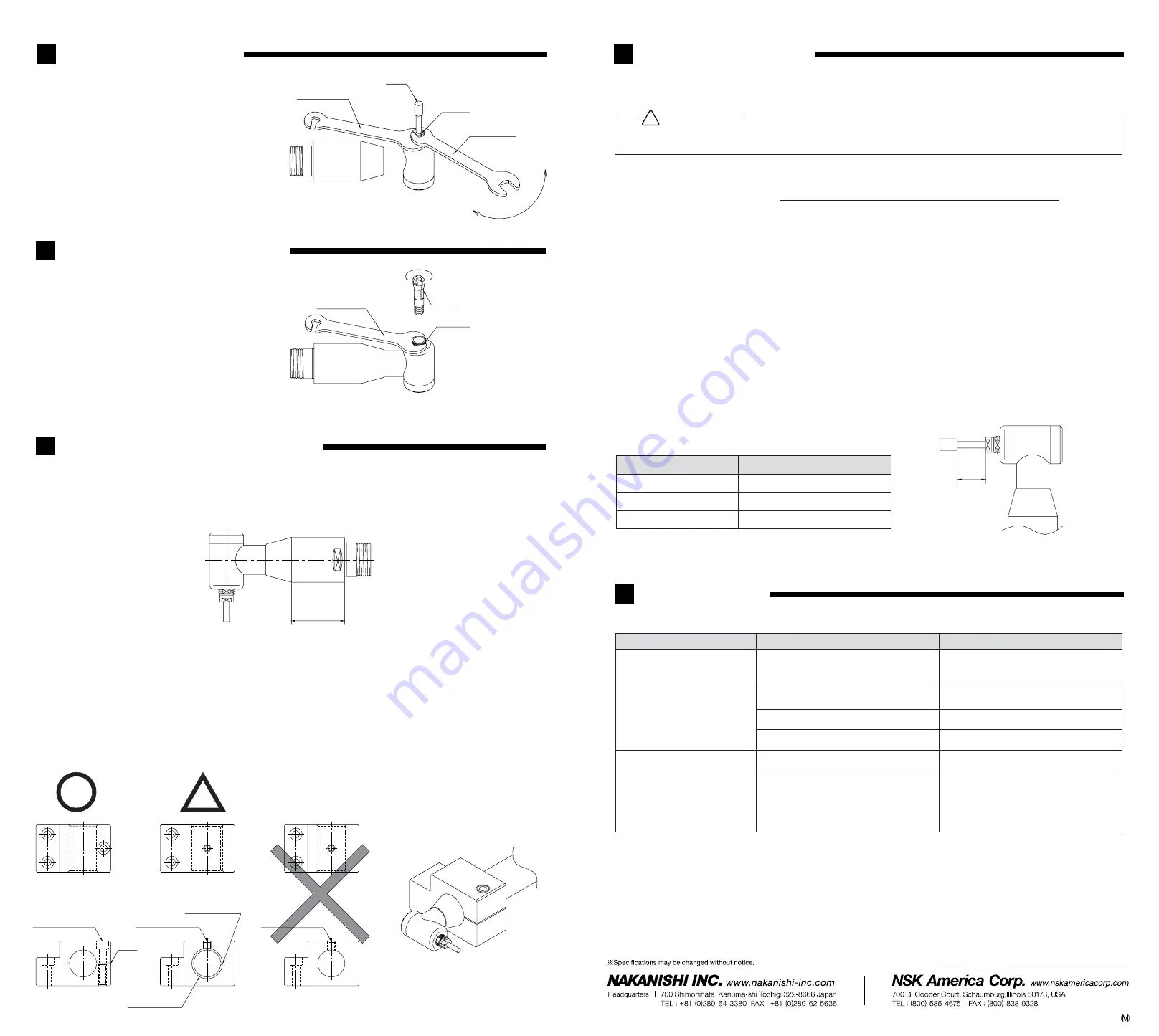

①When mounting the spindle avoid the area where bearings are located. If the spindle is mounted

inappropriately, this will cause and damage to the spindle.

(Refer to the clamping area drawing in

)

②The installation shown in

is the recommended installation method.

(In case the above is impossible, install as shown in

)

When installing a spindle, it is not recommended to fix the spindle with a fastening bolt in direct

contact with the spindle body as shown in

.

This can cause deformation of the spindle body and damage internal components.

(27)

(clamping area)