EN

WWW.NAKAYAMATOOLS.COM

1

Attention!

To keep the sprayer perfect in performance, please follow the instruction printed in this page.

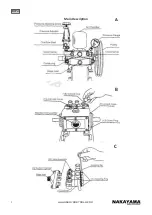

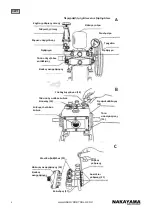

Operation Instruction

1. Check every fastener and make sure that the sprayer and the motor are installed firmly on the frame.

2. Set the two pulleys in a straight line, and the belt in an appropriate tightness.

3. Every joint of the hoses must be tightened to prevent from leaking.

4. Before starting the motor, shut off the (55) Cock (Valve) , loose the (57) Pressure Adjusting Screw and pull the (70) Pressure

Adjuster to the top.

5. Start the motor to power sprayer, keep a proper revolution. Press the (70) Pressure Adjuster to the bottom. Keep the

pressure around 21-35Kgs by adjusting the (57) Pressure Adjusting Screw.

6. Open the (55) Cock (Valve) to start spraying.

7. After the spraying is over, pull the (70) Pressure Adjuster to the top and operate the sprayer with fresh water to clean out

the remaining chemicals.

Pump Lubrication

1. Replace the engine oil after the sprayer has been used for the first 10 hours, 50 hours, and thence every 70 hours.

2. Drain away the dirty engine oil by screwing off the (14) Drain Plug.

3. After the (14) Drain Plug is screwed on, remove the (2) oil Inlet Cover and refill #30-40 clean engine oil.

4. Keep the oil level at 2 / 3 of the (13) oil Gauge.

5. Always fill the (34) Grease Cups with grease. Screw on the (34) Grease Cups 2-3 cycles every 2 hours of spraying.

Troubleshooting

a. Feeding Failure & Pressure Instability

1. Check whether the (87) Suction Hose is leaking or is stuck.

2. Open the (55) Cock (valve) to release the surplus air.

3. Remove the (43) Suction Chamber and the (49) Water Outlet Chamber check if the (37) Valve Assembly are stuck or

damaged.

b. Pressure Insufficiency

1. Check whether the pressure has been adjusted properly.

(Refer to the operation instruction No. 5)

2. Check whether the belt is too loose.

3. Check whether the Spray Hose and the couplings are broken and damaged.

c. Cylinder Leakage.

1. Remove the (23) Gland cover and wind up the (29) Adjusting Rings.

2. If still in vain, replace the (32) V-packings in the (35) Cylinder.

* The manufacturer reserves the right to make minor changes to product

design and technical specifications without prior notice unless these

changes significantly affect the performance and safety of the products.

The parts described / illustrated in the pages of the manual that you

hold in your hands may also concern other models of the manufacturer’s

product line with similar features and may not be included in the product

you just acquired.

* Please note that our equipment has not been designed for use in

commercial, trade or industrial applications. Our warranty will be voided

if the machine is used in commercial, trade or industrial businesses or for

equivalent purposes.

* To ensure the safety and reliability of the product and the warranty

validity, all repair, inspection, repair or replacement work, including main-

tenance and special adjustments, must only be carried out by technicians

of the authorized service department of the manufacturer.

Technical Data NS3600/NS2500

Capacity:

36 l/min. / 25l/min.

Dimensions:

36,5X30,5X34cm/ 33Χ29Χ30cm

Warning:

Please add SAE30 oil

before using the pump for the

first time!

Summary of Contents for NS2500

Page 1: ...Ns2500 ns3600 Owner s manual Art Nr 010258 010265 WWW NAKAYAMATOOLS COM...

Page 3: ...EN WWW NAKAYAMATOOLS COM 2 B C Main Description...

Page 5: ...GR WWW NAKAYAMATOOLS COM 4 B C 18 15 01 13 21 22 24 17...

Page 6: ......

Page 7: ......

Page 8: ......