WWW.NIKOLAOUTOOLS.GR

7

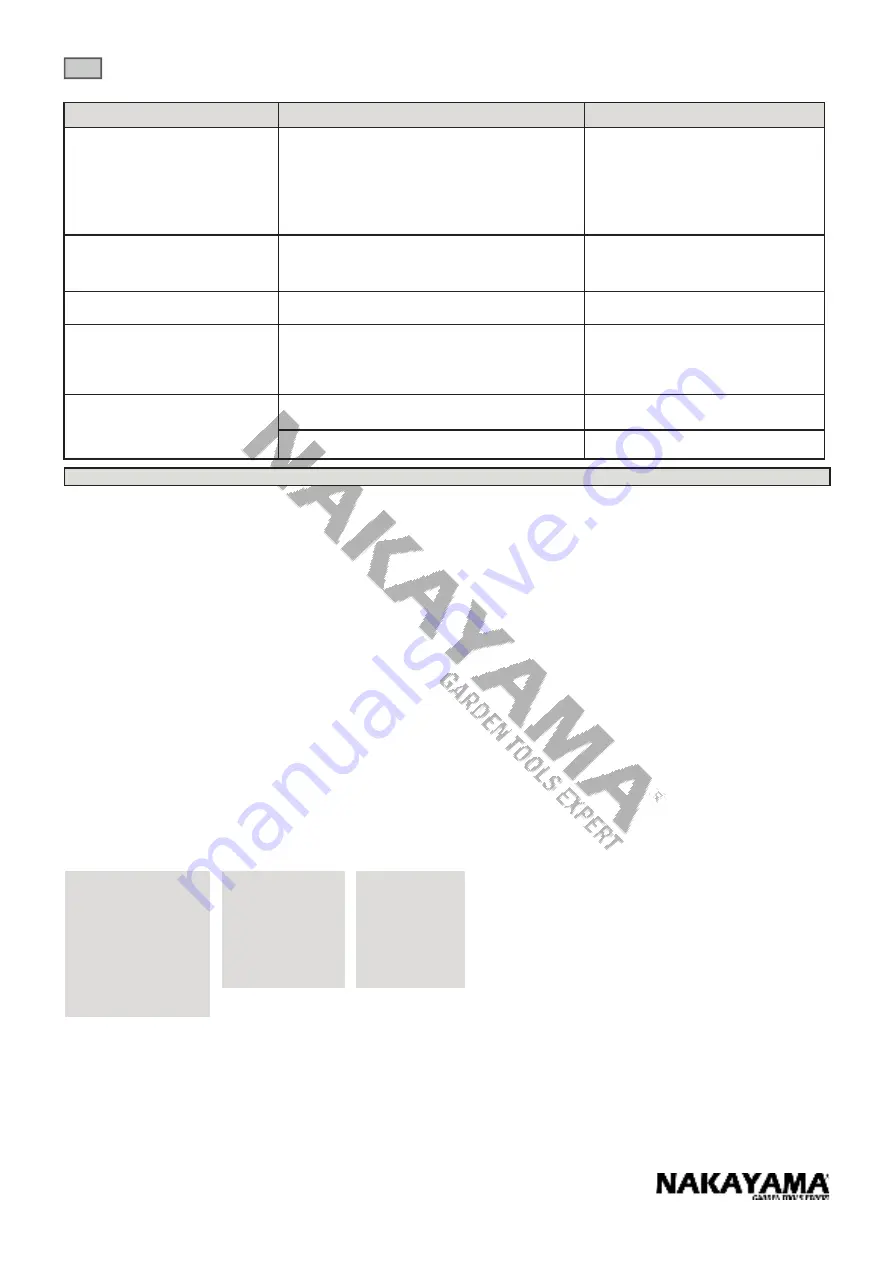

Problem

Cause

Solution

Reduced efficiency of power and speed.

Choke not open.

Muffler ventilation blocked.

Moving parts worn out.

Problem with the automatic speed governor.

Low ignition efficiency.

Valve gap too wide.

Combustion residues in the cylinder.

Open the choke.

Replace the muffler.

Check or replace.

Adjust the speed governor.

Replace the spark plug or the flywheel.

Adjust the gap.

Clean the cylinder.

Large variation in speed.

Problem with the automatic speed governor.

The type of carburetor is not suitable for the machine.

Incorrect setting of the gap.

Adjust the speed governor.

Replace the carburettor.

Adjust the gap.

Speed too high.

Problem with the governor slider.

Correctly adjust or reposition the slider.

Abnormal sound.

Incorrect adjustment of the valve gap.

The camshaft gear is damaged.

Adjust the valve gap.

Replace the camshaft.

Carburetor leakage.

Pin valve stuck.

Lightly tap or clean carburettor.

O-Ring deformed.

Replace.

PUMP (Images L, M, N)

Operating instructions

1. Check all connectors and other connection points.

2. Align pulleys and adjust belt tension.

3. Each tube joint must be tightened securely to prevent leakage.

4. Before starting the engine, close the valve. Untighten the pressure adjusting screw and pull the pressure regulator upwards.

5. Start the engine so that the sprayer is powered, set the speed to the appropriate level. Push the pressure regulator down. Maintain the pressure between

21-35 Kgs through the pressure adjustment screw.

6. Open the valve to start spraying.

7. After the end of spraying, pull the pressure regulator upwards and run the sprayer with fresh water to clean up any chemical residue.

Lubrication

1. Replace the engine oil after the first 10 hours of operation, then after 50 hours of operation and then every 70 hours of operation.

2. Remove used oil by unscrewing the drain plug.

3. After the drain plug is screwed in, remove the oil inlet cap and refill with new #30-40 engine oil.

4. Maintain the oil level at 2/3 of the oil sight glass.

5. Regularly replenish grease lubrication points. Screw in the grease cups 2-3 cycles every 2 hours of spraying.

Troubleshooting

A. Power supply failure & pressure instability

1. Check if the suction hose is blocked or leaking.

2. Open the valve to release the air.

3. Remove the suction chamber and water outlet chamber and check if the valve is stuck or damaged.

Β. Leakage from the head

1. Remove the protection cover and screw on the adjusting rings.

2. If the problem persists, replace the cylinder sealing components.

Image L

1. Air Chamber

2. Pressure adjusting screw

3. Pressure adjuster

4. Pulley

5. Overflow pipe

6. Valve

7. Suction hose

8. Spray hose

9. Pressure Gauge

Image M

1. Oil inlet cap

2. Crank case

3. Drain plug

4. Required oil level

Image N

1. Valve assembly

2. Adjustment point

3. Adjustment point

4. Water inlet

5. Suction chamber

EN

Summary of Contents for NS6200

Page 1: ...RO WWW NIKOLAOUTOOLS GR ART NO SL NS6200 025276 en HU FR BG el IT...

Page 2: ...WWW NIKOLAOUTOOLS GR 2...

Page 3: ...WWW NIKOLAOUTOOLS GR 3...

Page 18: ...WWW NIKOLAOUTOOLS GR 18 K B 25 50 0 7 0 8mm 100 2 B 0 7 0 8mm EL...

Page 22: ...BG 22 WWW NIKOLAOUTOOLS GR A B C 25 50 0 7 0 8 100 2 B C D K 0 7 0 8...

Page 42: ......