EN

WWW.NAKAYAMATOOLS.COM

4

● The data in the table is trial value of our company not the confirmed value. The amount of spraying mist and working pressure change with the environ-

ment.

Adding Liquids

Please lay this machine on the aclinic ground when adding liquids.

Please use the filter screen when you adding liquids. The filter screen can protect the liquid plug from jam, for the jam can result in abnormal jet.

Please be slow when adding chemical in order to avoid overbrimming. Once overbrimmed, please wipe it dry and clean with gauze so that the chemical

doesn’t flow into the battery and electric pump. The chemical liquids can corrupt the electric equipment and short the life of this machine greatly.

It is strictly prohibited to use menstruums easy to curdle when meeting heat. For the heat generated by the working of liquid pump is easy to curdle that

menstruum so that the liquid pump doesn’t work.

Note:

● Please make sure that the switch of electric power is turned off before adding the chemical.

● There is a scale on the side of chemical tank, please add chemical liquid according to the quantity of work.

● It is strictly forbidden to spray highly acid liquid, paint and volatile menstruum.

Warning:

● Please follow the prescribe of the manufacturer of chemical menstruum to mix chemical liquid, or it will harm crops and body.

● Be sure to mix the chemical liquids to be well-proportioned in other containers. The filter must be used when filling chemical liquids into the chemical tank.

● Please fasten the chemical cap after finishing filling.

Misting

Warning: Be sure to check the battery after adding water into chemical tank.

The liquid pump must avoid idler revolutions in order not to harm it.

1. Starting

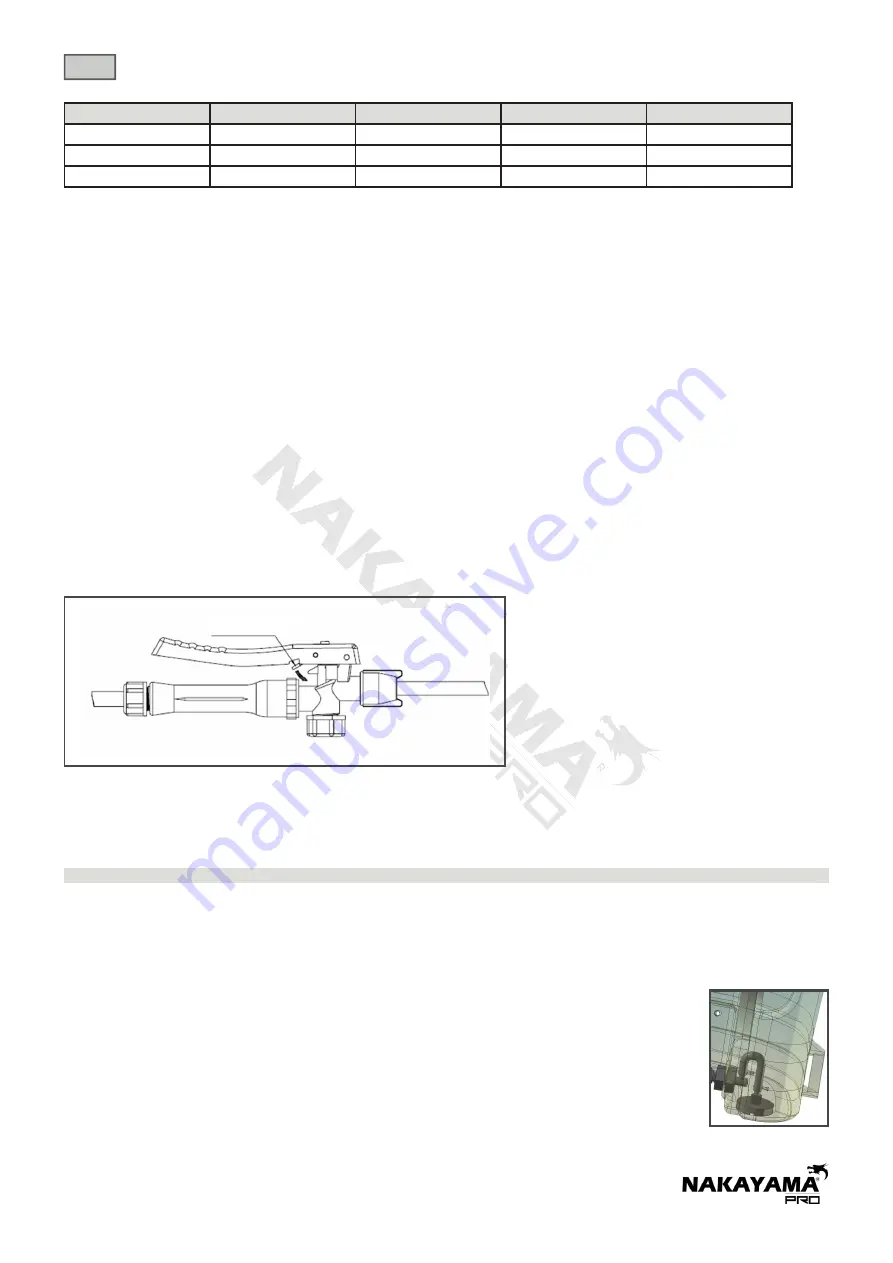

Adjust the switch to the “-”. Grasp the handlebar open the check valve and then spray.

2. Stop

● Adjust the switch to “0”, the liquid pump stop.

● Release the handlebar, stop operation (even no off the power switch).

Lock catch

When the electric quantity is low, the water flow will be gradually little, need recharge.

After spraying, discharge remaining liquid out, wash the inside wall of the chemical container with clean water. Then add fit water into the chemical tank,

start liquid pump, rotate 2~3 minute. Make the spraying pipe, inside pump and nozzle washed clean, then swill the liquid in the chemical tank. Then, restart

liquid pump to discharge the remaining liquid out completely. After that, the power switch is adjusted the place “0”.

Daily maintenance

The following maintenance should be done after daily job

1) Cleaning the oil and dust on the surface machine

2) Clean chemical tank with clean water and dry it.

3) Check all the connections whether there is leakage of water or fuel. If there is leakage, remedy procedures are very necessary.

4) Check all the screws to see if they are loose or lost. If there is , please screw tightly or replace.

5) The battery must be charged before depositing. Charge before each using in case short power.

6) The machine after maintenance should be put in dry and ventilating place. It must be far away from fire source and avoid sun-

light.

Deposit for a long time

The machine deposit for a long time should maintenance as follows:

1) Clean the machine surface carefully.

2) Discharge medicine in the tank and pump, clean them with clean water.

3) The battery must be charged before storing. If deposit for a long time, it should be charged every two months.

4) All the plastic parts must neither exposed to the sunlight nor pressed by heavy matter

Maintenance

Type of nozzle

Diameter of nozzle (mm)

Flow (L/min)

Working pressure (Mpa)

The amount of Nozzle

Taper Nozzle

1.0

0.8

0.15 ~ 0.35

1

Sector Nozzle

0.7

0.48

0.15 ~ 0.4

1

F Nozzle

1.5

1.2

0.15 ~ 0.25

2