WWW.NAKAYAMATOOLS.COM

EN

10

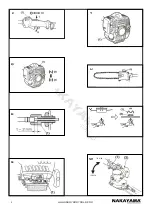

Assembly instructions and main adjustments

Mounting the engine (A)

1. Push the shaft tube toward the clutch housing and rotate it by hand to check that the drive shaft is en gaged with the gears.

2. Insert the shaft tube into the clutch housing until it bottoms, and align the positioning holes on the clutch housing and the shaft tube and install the screw.

When difficult to engage, twist the engine slightly.

3. Fasten the clamp securely with two screws.

Important: Tighten the screws gradually by turning them.

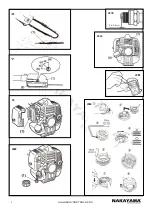

Connecting the throttle wire (B)

1. Remove the air cleaner cover.

2. Connect the end of the throttle wire to the joint on the top of the carburettor.

(1) M3 screw

(2) Adjuster

(3) Idling adjusting screw

(4) Full on stopper

(5) Insert the cable to the end of the adjuster

1. Connect the throttle wire with carburettor. Insert the cable to the end of adjuster fix the throttle cable by tighten ing the M3 screw. (Tightening torque: 0.4

- 0.8 N.m.)

2. Make sure the TOPPER-PLATE of carburettor moves to contact with the idling adjusting screw and the wing-arm of carburettor moves to contact with Full on

stopper by gripping throttle lever.

Connecting the switch wires

Connect the switch wires between the engine and the main unit. Pair the wires of the same colour.

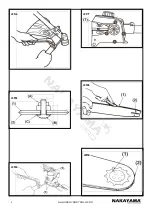

Suspension Point (C)

Note: The suspension point must match the location of the arrow mark.

(1) Suspension Point

(2) Arrow mark

Installing the handle (D), (E), (F)

Note: The handle is put during the arrow mark.

(1) Minimum spacing

(2) 48cm

Mount the handle to the shaft tube and suspension point it at a location that is comfortable to you.

Insert the grip to the shaft tube. Fasten the clamps with screws.

Install the J-shaped handle to the shaft tube and clamp at a position best for your job.

Joint attachment (G)

(1) Knob bolt

Insert the attachment to the main shaft. Tighten the knob bolt securely.

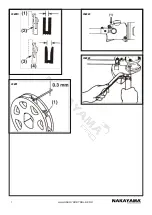

Installing the cutting attachment guard (H)

(1) Cutting attachment guard

(2) Plate

(3) Screw

Put the cutting attachment guard on the gearbox, att ach it with the 4 screws and hardware provided.

Installing the cutting head (I)

1. While locking the gear shaft, by inserting the supplied tool into the upper holder on the gear box, loosen and remove the hexagon nut (left-handed).

2. Then screw in the cutting head to the gear shaft over the holders Hand-tighten it securely.

Harness

Warning: Always wear the provided harness when using the machine!

Always make sure the machine is hooked securely to the harness.

If you don’t, you will be unable to control the machine safely. This can result in injury to yourself or others. Never use a harness with a defective quick release

or any other damage.

1. Wear the provided harness without twisted bands, with the hanger on your right side.

Balance the unit

1. Hook your machine to the hanger.

2. Adjust the bands of the harness to have the blade parallel to the ground when standing in your normal working position to provide you most effectiveness

and comfort on operating the machine.

3. In order to prevent the hanger position to change during operation, turn up the extra part of the band from the buckle.

4 . When correctly adjusted, check the correct working of the harnesses “quick release”.

Quick Release

The harness is equipped with a “quick release”devise.

To release the machine from the harness in emergency situations, please follow the procedure as explained below.

Warning: Make sure to check proper working of the quick release device before operating the machine. Make sure to hold the unit securely when using the

quick release.

While holding the unit by your right hand securely, press both sides of the buckle, sides of the buckle.

Summary of Contents for PS3100

Page 1: ...en el WWW NAKAYAMATOOLS COM ART NO PS3100 PS5100 029106 029090...

Page 3: ...3 WWW NAKAYAMATOOLS COM i l g 1 j h k m n o...

Page 4: ...4 WWW NAKAYAMATOOLS COM t p q u V W TIGHTEN LOOSEN r s...

Page 5: ...5 WWW NAKAYAMATOOLS COM 6 5 3 0 6 0 9mm 4 2...

Page 6: ...6 WWW NAKAYAMATOOLS COM 14 15 18 19 16 17...

Page 7: ...7 WWW NAKAYAMATOOLS COM 22 21 22 20...

Page 17: ...17 WWW NAKAYAMATOOLS COM EL 1 2 3 4 5 15...

Page 18: ...18 WWW NAKAYAMATOOLS COM EL 60 3 m 1 2...

Page 23: ...23 WWW NAKAYAMATOOLS COM EL 3 5mm X 1 2 1 2 Y 1 40 1 2...

Page 24: ...24 WWW NAKAYAMATOOLS COM EL Z 1 ON OFF OFF 2 1 2 3 Z1 1 Z2 1 25 50 100 0 6 0 7mm ON OFF...

Page 26: ...26 WWW NAKAYAMATOOLS COM EL Z17 1 Z18 1 2 Z19 1 2 Z20 1 2 3 4 Z21 0 3mm 1 1 0 6 0 7 mm 2...

Page 27: ......