WWW.NAKAYAMATOOLS.COM

EN

16

If the blades become so worn down that it is no longer possible to eliminate the gap between them, you should contact the au thorized servicing dealer from

which you purchased your trimmer to have the blades resharpened or replaced.

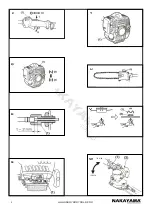

Transmission (Z16)

The reduction gears are lubricated by angled transmission grease in the transmission.

Supply new grease every 25 hours of use or more often depending on the job condition.

When adding lubricant, use a grease gun to insert lubri cant into the three grease nipples located on the trans mission.

(1) Grease fitting

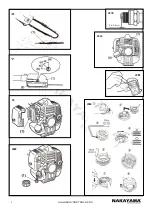

Oiling port (Z17)

(1) Oiling port

Dismount the guide bar and check the oiling port for clogging.

Guide bar (Z18)

Remove sawdust in the bar groove and the oiling port.

(1) Groove (2) Oiling port

(Type: Sprocket nose)

Grease the nose sprocket from the feeding port on the tip of the bar.

(Z19):

(1) Grease port (2) Sprocket

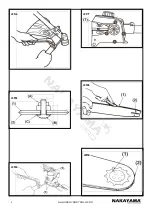

The bar rail should always be a square. Check for wear of the bar rail. Apply a ruler to the bar and the outside of a cutter. If a gap is observed between them,

the rail is normal. Otherwise, the bar rail is worn. Such a bar needs to be corrected or replaced.

(Z20): (1) Ruler, (2) Gap, (3) No gap. (4) Chain tilts

Sprocket (Z21)

Check for extensive wear, and replace it when the teeth are worn over 0.3 mm.

(1) Sprocket

Saw chain

Warning: It is very important for smooth and safe operation to keep the cutters always sharp.

Your cutters need to be sharpened when:

Sawdust becomes powder-like.

You need extra force to saw in.

The cut way does not go straight vibration increases.

Fuel consumption increases.

Transmission

The reduction gears are lubricated by angled transmission grease in the transmission.

Supply new grease every 25 hours of use or more often depending on the job condition.

When adding lubricant, use a grease gun to insert lubri cant into the three grease nipples located on the trans mission.

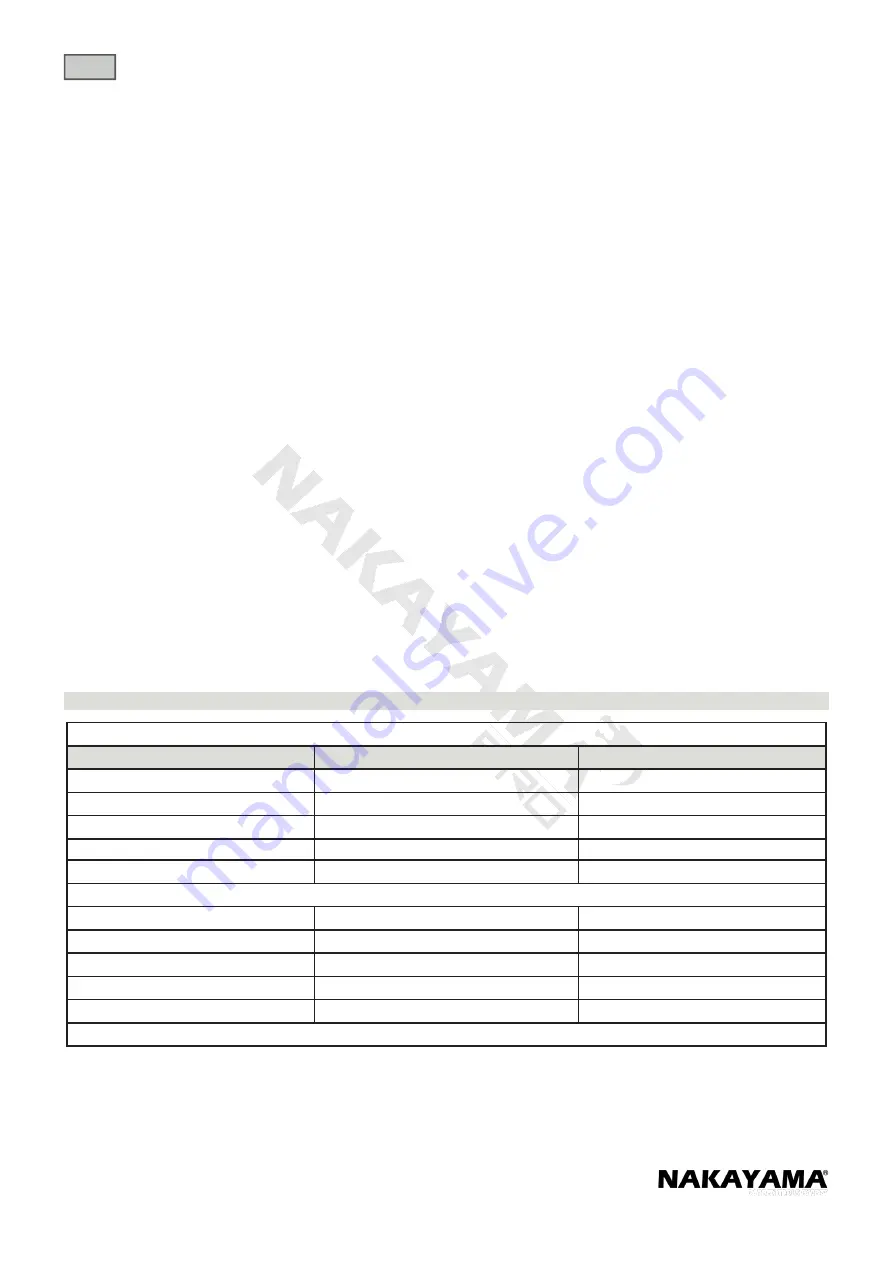

Troubleshooting

Case 1. Starting failure

Check

Possible causes

Action

Fuel tank

Incorrect fuel

Drain it and use correct fuel

Fuel filter

Fuel filter is clogged

Clean

Carburettor adjustment screw

Out of normal range

Adjust to normal range

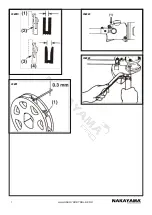

Sparking (No spark)

Spark plug is faulty/wet, plug gap is incorrect

Clean/Dry, correct (gap: 0.6-0.7mm)

Spark plug

Disconnected

Re-tighten

Case 2. Engine starts but does not keep running/hard restarting

Fuel Tank

Incorrect fuel or staled fuel

Drain it and use correct fuel

Carburettor adjustment screw

Out of normal range

Adjust to normal range

Muffler, cylinder (exhaust port)

Carbon is built up

Wipe away

Air cleaner

Clogged with dust

Wash

Cylinder fin, fan cover

Clogged with dust

Clean

When your unit seems to need further service, please consult with our service shop in your area.

Summary of Contents for PS3100

Page 1: ...en el WWW NAKAYAMATOOLS COM ART NO PS3100 PS5100 029106 029090...

Page 3: ...3 WWW NAKAYAMATOOLS COM i l g 1 j h k m n o...

Page 4: ...4 WWW NAKAYAMATOOLS COM t p q u V W TIGHTEN LOOSEN r s...

Page 5: ...5 WWW NAKAYAMATOOLS COM 6 5 3 0 6 0 9mm 4 2...

Page 6: ...6 WWW NAKAYAMATOOLS COM 14 15 18 19 16 17...

Page 7: ...7 WWW NAKAYAMATOOLS COM 22 21 22 20...

Page 17: ...17 WWW NAKAYAMATOOLS COM EL 1 2 3 4 5 15...

Page 18: ...18 WWW NAKAYAMATOOLS COM EL 60 3 m 1 2...

Page 23: ...23 WWW NAKAYAMATOOLS COM EL 3 5mm X 1 2 1 2 Y 1 40 1 2...

Page 24: ...24 WWW NAKAYAMATOOLS COM EL Z 1 ON OFF OFF 2 1 2 3 Z1 1 Z2 1 25 50 100 0 6 0 7mm ON OFF...

Page 26: ...26 WWW NAKAYAMATOOLS COM EL Z17 1 Z18 1 2 Z19 1 2 Z20 1 2 3 4 Z21 0 3mm 1 1 0 6 0 7 mm 2...

Page 27: ......