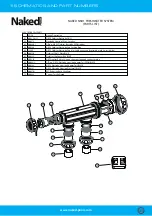

11. SCHEMATICS AND PART NUMBERS

27

26

25

24

28

SL-15PP-NKD1

N00364

N00895

POWER PACK

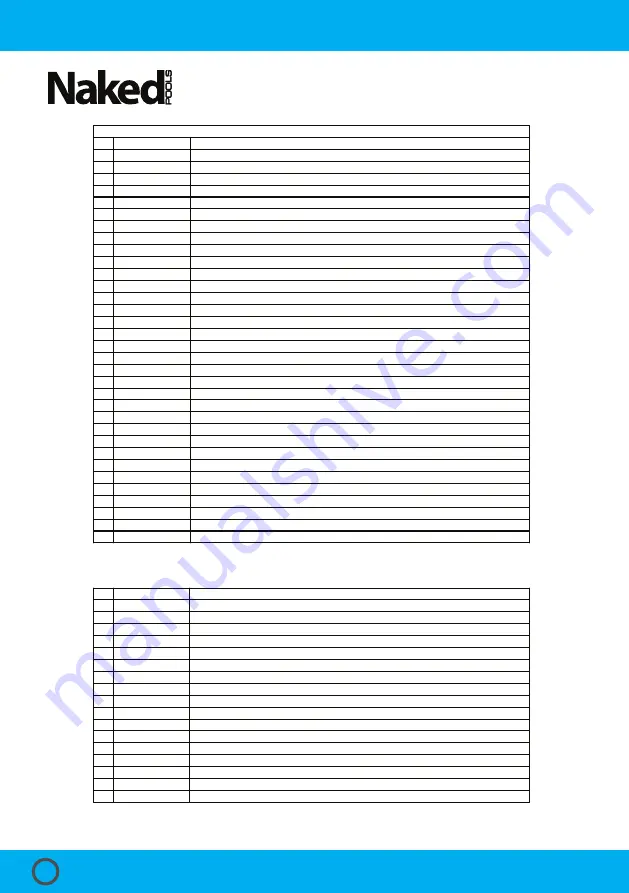

PARTS AND COMPONENTS (Not shown in schematic)

N00027

Thermostat 100degC

28

N00883

Ioniser Plug SL-13 Female End Complete with 2 x SL-09 Wire Looms

N00504

SM Cooling Fan 40x40x20mm (not in all models)

Power Cord-Au

N00049

N00883

Thermostat 100degC

27

N00027

Cooling Fan 40x40x20mm (not in all models)

26

N00504

Power Cord-Au

25

N00011

Internal Tooth Washer for Earth M5 S/S

24

N00049

Earth Nut M5 S/S

23

N00051

Earth Screw M5 S/S

22

N00050

NKD1 Snap Fit Gauze BLACK

21

N00370

20

N00369

NKD1 Bottom Vent Cover BLACK

19

N00368

Screw Pan Head M6x10 Stainless Steel 304

18

N00503

Circuit Breaker 3amp with 6.3mm push on

17

N00018L

16

N00054

15

N00488

13

N00869

AC Socket Round - Pump Outlet Flush Mount White (Top Wire Entry)

12

N00498

Transformer 232VA for 15g/hr Model

8

N00496

7

Multi Triac Shunt PCB

6

NKD1 Decal Sticker (set of 2)

5

NKD1 Front Flap BLUE

4

NKD1 Vent Naked BLACK

3

NKD1 Cover BLACK

2

Wire Loom SL-12 - Multi PCB TB-GND Pin 1 to LCD PCB RB-GND Pin 1 BLACK

Naked DESCRIPTION

1

Naked NKD1 Power Pack

CODE

11

9

N00356

NKD1 Mounting Bracket

Grommet EC RP 6N-4 Cable Strain Relief Bush

Screw M3x12 Stainless Steel 304 (Fan)

NKD1 Fan Support Plate BLACK

Ioniser Plug SL-13 Female End Complete with 2 x SL-09 Wire Looms

N00693

N00870

N00367

N00842

N00022-1

N00011

NKD1 LCD Display PCB

Aluminium Die Casting with BLACK Outer Coating

10

N00453-2

Internal Tooth Washer for Earth M5 S/S

NKD1 Freshwater System Outer Box

46

N00079

45

N00873

Sleeve - NKD1 Freshwater System

44

N00876

NKD1 Power Supply Carton Box

43

N00067

42

N00052

Screw M4 x 8 Stainless Steel (Front Cover)

41

N00053

Screw Self Tapping M5x25 Stainless (Wall)

37

N00008

36

Wire Loom SL-11 - Ribbon Cable with RED line and Header Sockets

35

Wire Loom SL-05 - Terminal Block 1 Pin 2 to Terminal Block 2 Pin 2 RED

34

Wire Loom SL-04 - Circuit Breaker LINE to PCB A BROWN

33

Wire Loom SL-03 - AC Socket L to PCB PUMP-L BROWN

32

Wire Loom SL-02 - AC Socket N to PCB N BLUE

31

Wire Loom SL-01 - Circuit Breaker LOAD to Transformer Active BROWN

30

Washer 37x37x2.5 Zink Plated

CODE

40

38

N00036

Green Wall Plugs

Screw M3x6 Stainless Steel (Triac Connection and PCB)

NKD1 Operating Manual

N00485

N00484

N00348

N00224

N00223

N00207

N00047

N00217

Wire Loom CC-05 - Earth Wire

Cable Tie 3mm

39

N00560

14

N00501

Grommet Rubber AUX Hole up to 19mm

Oxidiser Plug SL-10 Male End Complete with Power Supply Looms - Grease Filled

Naked Description

(PARTS LIST)

NAKED NKD1 FRESHWATER SYSTEM

www.naked-pools.com

30