521-OM0108.88

Copyright

2009 Nalco Company

6-5

Technical Help

(630) 305-CHEM

3D TRASAR

5500 - Installation & Operation Manual

6.3

Bio-Reporter Selection

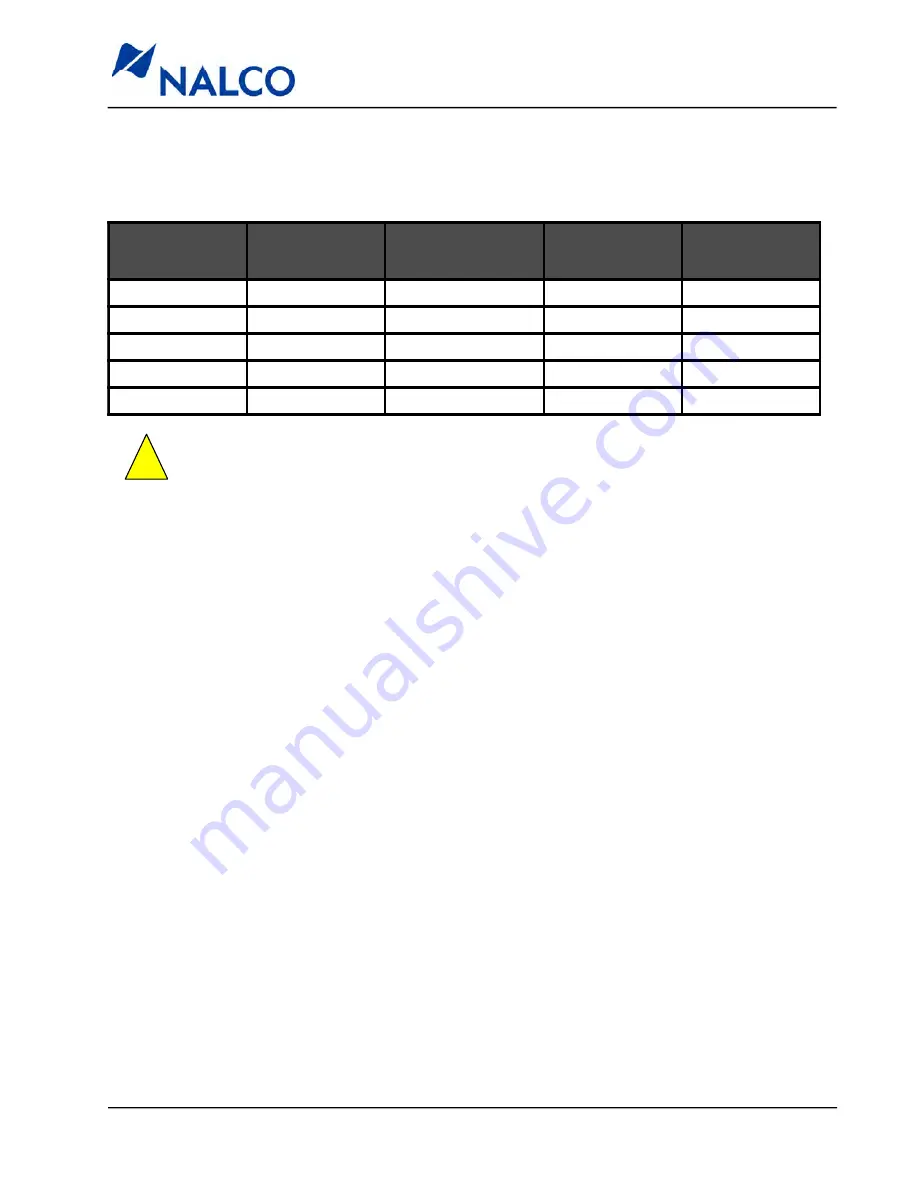

The bio-reporter product comes in both liquid and pellet form. Before starting up 3D TRASAR Bio-

Control, refer to the table below to make sure you are using the appropriate product.

!

Important!

3DTBR10 is formulated in concentrated sulfuric acid. Please contact your

Nalco Representative for recommendations on fluid handling equipment compatible with

concentrated acid.

6.4

3D TRASAR Bio-Control/3D TRASAR Bio-Shock Start-Up

Procedure

We recommend running a system under ORP control with a control range of

±

20mV for a week

before proceeding to 3D TRASAR Bio-Control. The ORP readings during this period should be

evaluated. If the ORP readings swing much wider than the control band of

±

20mV then the entire

oxidant feed system should be evaluated. Common reasons for poor ORP control include:

•

The Oxidizing biocide pump is air locking

•

The Oxidizing biocide is entering the system in front of the intake for the controller

•

The Oxidizing biocide is being fed into a dead leg or a potential dead leg (e.g. Makeup water

tank)

•

The oxidizing biocide pump rate is set too high or too low

•

The system does not recirculate properly.

Oxidant feed issues should be resolved prior to 3D TRASAR Bio-Control initiation.

STEP 1

- Turn off oxidant feed to allow cooling system residual to fall below 0.1 ppm TRH

(Depending on system volume this can take as long as 24 hours). Measure the total halogen

residual with a DR/2800 or DR/890 DPD test (

Reagent P/N 460-S0461.87

).

STEP 2

- Verify BioReporter and oxidant feed systems are ready for service. DO NOT feed the

oxidant and BioReporter in close physical proximity. Make sure both feed points are sufficiently

separated in distance that thorough mixing of each occurs. Failure to do so will negatively impact

the performance of 3D TRASAR Bio-Control. Do not feed bio-reporter or Oxidizing biocide directly

upstream of the 3D TRASAR controller sample point.

Bio-Reporter

Product

Bio-Reporter

Type

Recommended

System Volume

Gallons

"Do not Exceed"

System Volume

Gallons

Blowdown

Upper Limit GPM

3DTBR06

Liquid (0.6%)

0-12,000

30,000

N/A

3DTBR8

Solid pellet (8%)

12,000 to 30,000

100,000

200

3DTBR20

Solid pellet (20%)

30,000 to 60,000

1,000,000

500

3DTBR40

Solid pellet (40%)

60,000 to 2,000,000

2,000,000*

1,000

3DTBR10

Liquid (10%)

>5,000,000

N/A

N/A