3D TRASAR

5500 - Installation & Operation Manual

521-OM0108.88

Copyright

2009 Nalco Company

9-7

Technical Help

(630) 305-CHEM

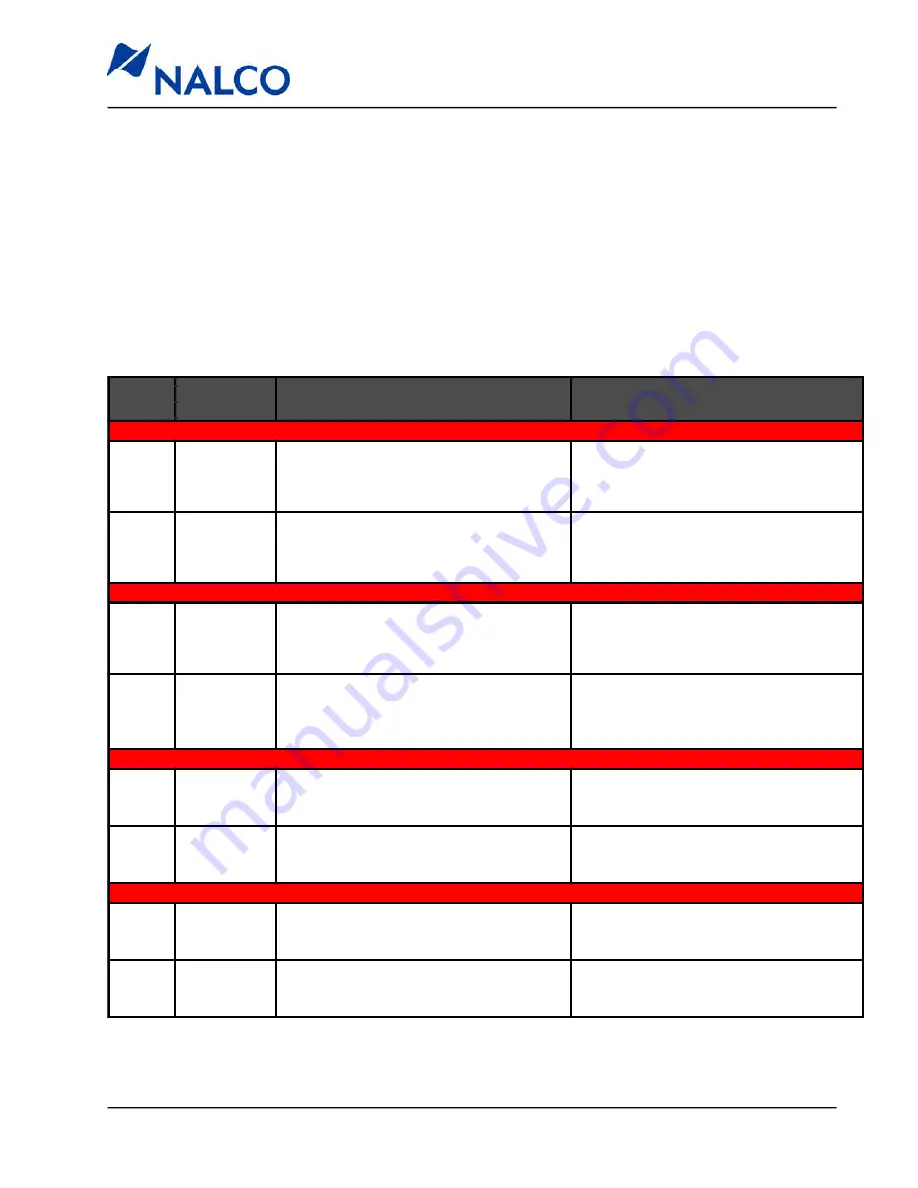

Alarm

Type

Indication

Probable Cause

Corrective Action

TRASAR, Tagged Polymer, ORP, pH (Caustic Control)

High

Measurement

exceeds High

Alarm threshold

1) Sensor probe is out of calibration.

2) High Alarm threshold set too low.

3) Chemical feed rate too high causing "overshoot".

4) Chemical pump siphoning causing overfeed.

5) Process leak or other contaminant in system.

1) Check calibration and recalibrate if needed.

2) Readjust alarm threshold.

3) Reduce chemical feed rate.

4) Elminate condition causing siphoning.

5) Confirm (with other data) and eliminate source.

Low

Measurement

below Low

Alarm threshold

1) Sensor probe is out of calibration.

2) Low Alarm threshold set too high.

3) Chemical feed rate too low or interrupted.

4) Product container empty.

5) Process leak or other contaminant in system.

1) Check calibration and recalibrate if needed.

2) Readjust alarm threshold.

3) Check feed line or increase chemical feed rate.

4) Refill/replace product inventory.

5) Confirm (with other data) and eliminate source.

pH (Acid Control)

High

Measurement

exceeds High

Alarm threshold

1) Sensor probe is out of calibration.

2) High Alarm threshold set too low.

3) Chemical feed rate too low or interrupted.

4) Product container empty.

5) Process leak or other contaminant in system.

1) Check calibration and recalibrate if needed.

2) Readjust alarm threshold.

3) Check feed line or increase chemical feed rate.

4) Refill/replace product inventory.

5) Confirm (with other data) and eliminate source.

Low

Measurement

below Low

Alarm threshold

1) Sensor probe is out of calibration.

2) Low Alarm threshold set too high.

3) Chemical feed rate too high causing "overshoot".

4) Chemical pump siphoning causing overfeed.

5) Process leak or other contaminant in system.

1) Check calibration and recalibrate if needed.

2) Readjust alarm threshold.

3) Reduce chemical feed rate.

4) Eliminate condition causing siphoning.

5) Confirm (with other data) and eliminate source.

Conductivity

High

Measurement

exceeds High

Alarm threshold

1) Sensor probe is out of calibration.

2) High Alarm threshold set too low.

3) Blowdown valve throttled too low or plugged.

4) Process leak or other contaminant in sy stem.

1) Check calibration and recalibrate if necessary.

2) Readjust alarm threshold.

3) Check blowdown valve for proper operation.

4) Confirm (with other data) and eliminate source.

Low

Measurement

below Low

Alarm threshold

1) Sensor probe is out of calibration.

2) Low Alarm threshold set too high.

3) Blowdown valve throttled too high or stuck open.

4) Process leak or other contaminant in sy stem.

1) Check calibration and recalibrate if necessary.

2) Readjust alarm threshold.

3) Check blowdown valve for proper operation.

4) Confirm (with other data) and eliminate source.

Temperature

High

Measurement

exceeds High

Alarm threshold

1) RTD probe is out of calibration

2) High Alarm threshold set too low.

3) Cooling system problem. Note: PVC piping is rated

for 140 F max.

1) Verify temperature using a thermometer.

2) Readjust alarm threshold.

3) Diagnose and resolve cause of excessive bulk

water temperature.

Low

Measurement

below Low

Alarm threshold

1) RTD probe is out of calibration.

2) Low Alarm threshold set too high.

3) Cooling system problem. Note: Freezing will burst

piping.

1) Verify temperature using a thermometer.

2 ) Readjust alarm threshold.

3) Diagnose and resolve cause of low bulk water

temperature.

9.2

Alarm Screen Troubleshooting

Notes

:

1) Upon initial start-up measured levels may be low causing nuisance alarms. To prevent nuisance

alarms refer to the start-up procedures to select system Start-up alarm suppression (Section

4.10.11).

2) To reset an alarm it is necessary to eliminate the alarm condition by either.

• placing the control mode in “Off” temporarily

• adjusting the variable within the alarm limits

• or changing the alarm limits.