521-OM0108.88

Copyright

2009 Nalco Company

4-19

Technical Help

(630) 305-CHEM

3D TRASAR

5500 - Installation & Operation Manual

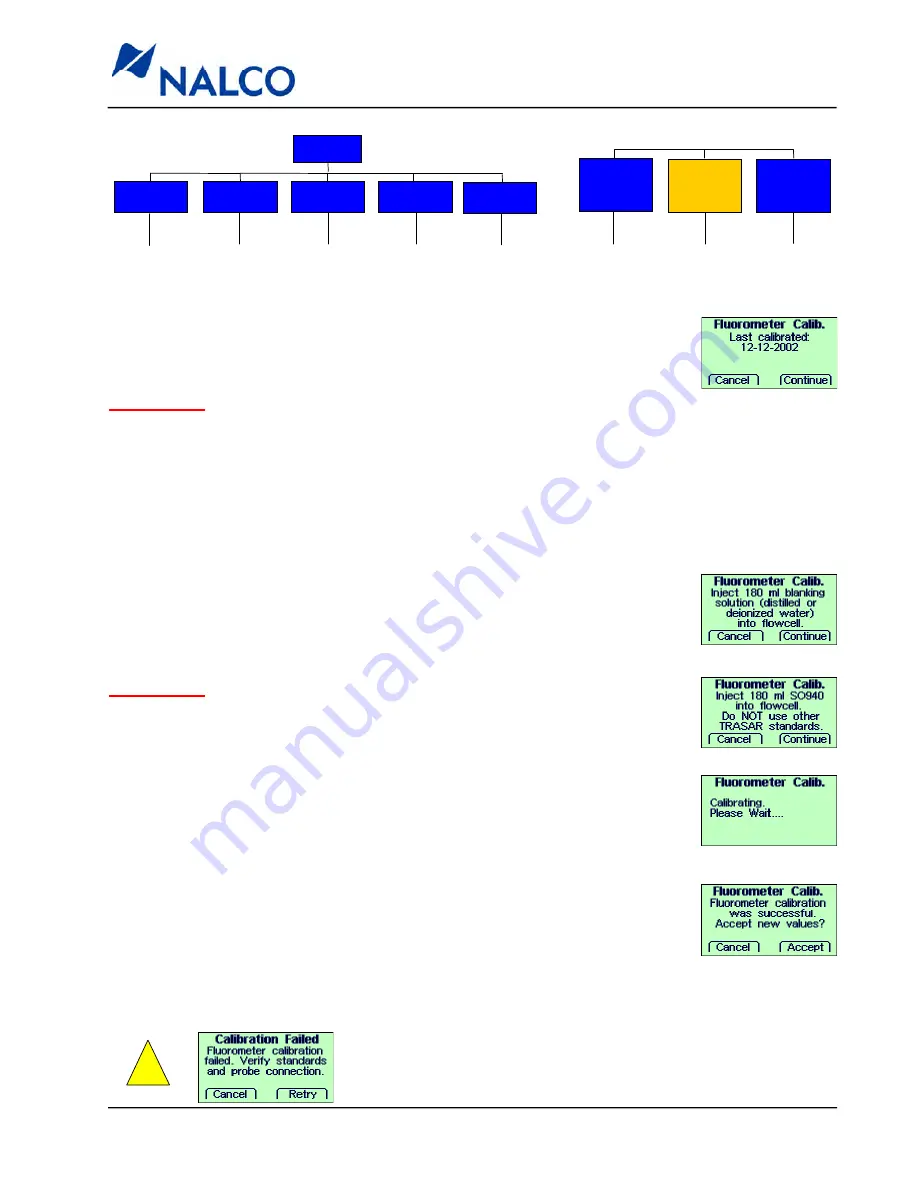

4.10.3 Fluorometer Calibration Screens

Select

Fluorometer

and follow screen directions to perform calibration:

STEP 1

Close fluorometer inlet valve and turn 3-way fluorometer discharge valve to

sample position.

IMPORTANT

: Bubbles trapped in fluorometer during injection can cause instru-

ment error. With the syringe

(P/N 500-P2147.88)

in a vertical position, tap the

syringe against a solid object to move the bubbles to the needle end of the

syringe. Then, force the bubbles out by pushing a small amount of solution

through the needle end of the syringe.

STEP 2

Clean the fluorometer by injecting acid with a syringe into the flow cell. Fill the

syringe with 60 ml of dilute acid. 10% Sulfuric Acid

(P/N 460-S0800.75)

is rec-

ommended. If iron fouling exists, use 1:1 HCl

(P/N 460-S0726.75)

for cleaning.

Screw the syringe onto the fitting, inject the dilute acid at a slow

, steady rate into

the flow cell, and allow it to stand for 2 minutes. Rinse well with water. Using the

flow cell brush

(P/N 500-P2817.88)

, gently push the brush down through the

opening and scrub the full length of the flowswitch and fluorometer tube.

IMPORTANT

: If using 1:1 HCl, do not leave the acid in the flow cell for more than

five minutes.

STEP 3

Following the screen prompts, use a second clean 60 ml syringe and slowly

flush the flow cell with 180 ml of blank solution. Then slowly inject another 180 ml

blank solution and allow it to remain in the flow cell by leaving the syringe at-

tached. Press

Continue

.

STEP 4

Following the screen prompts, use a third clean 60 ml syringe and slowly inject

the flow cell with 180 ml of calibration solution

(P/N 460-S0940.75)

and allow it

to remain in the flow cell by leaving the syringe attached. Press

Continue

.

STEP 5

Successful calibration will be indicated and must be “accepted”. Controller will

automatically re-boot after accepting calibration. Turn valves back to operating

positions.

Control

Settings

Alarm

Settings

Preferences

System

Info

Network

Information

Manual

Relay

Actions

Menu

Alarms

!

A failed calibration is most likely caused by insufficient flush-

ing, contaminated/incorrect standards, introduction of air

bubbles, excessive cell fouling, or a bad probe connection.