© by N&W GLOBAL VENDING S.p.A.

5

01-2016 4875 00

c

aNist�r

capacity

Canister capacities are expressed in grams and they

may deviate from indications, depending upon the spe-

cific weight of products

-1.80 lt. canister

coffee beans

760 gr

-0.85 lt. canister

Coffee beans

350 gr

-Instant canister

Chocolate

650 gr

ELECTRIC ENERGY CONSUMPTION

The electric energy consumption of the machine will

depend upon many factors such as the temperature and

ventilation of the room where the machine is installed,

the inlet water temperature, the boiler temperature, etc.

The calculated energy consumption shall be understood

as merely indicative.

Temperature reached

Wh

28

For 24h stand-by

Wh

833

moD�l

wit�

cappucciNator�

Temperature reached

Wh

87.8

For 24h stand-by

Wh

1790

The energy consumption calculated on the average va-

lues above shall be understood as merely indicative.

a

cc�ssori�s

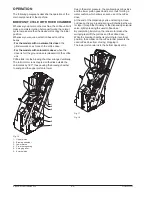

A wide range of accessories can be mounted on the

machine to vary its performances:

The assembly kits are supplied with mounting and test-

ing instructions that shall be strictly followed to preserve

the machine safety.

The installer is the sole person responsible for any dam-

age improper installation may cause to the machine or to

things and people.

Important !!!

The use of kits not type-approved by the manufacturer

can not guarantee the observance of safety standards,

in particular for live parts.

The manufacturer declines all responsibility for the use

of non type-approved components.

Assembly and any subsequent testing operation

must be carried out by qualified personnel who

have a specific knowledge of the machine opera

-

tion from the point of view of electric safety and

health rules.