S-54

03-M Series, WSM

DIESEL ENGINE

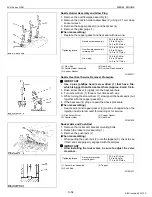

Nozzle Holder Assembly and Glow Plug

1. Remove the overflow pipe assembly (5).

2. Remove the nozzle holder assemblies (2) using a 21 mm deep

socket wrench.

3. Remove the copper gasket (3) and heat seal (4).

4. Remove the glow plugs (1).

(When reassembling)

• Replace the copper gasket and heat seal with new one.

W1020917

Nozzle Heat Seal Service Removal Procedure

IMPORTANT

Q

• Use a plus (phillips head) screw driver (1) that has a Dia.

which is bigger than the heat seal hole (Approx. 6 mm) 1/4 in.

1. Drive screw driver (1) lightly into the heat seal hole.

2. Turn screw driver (1) three or four times each way.

3. While turning the screw driver (1), slowly pull the heat seal (4) out

together with the copper gasket (3).

4. If the heat seal (4) drops, repeat the above procedure.

(When reassembling)

• Heat seal (4) and copper gasket (3) must be changed when the

injection nozzle is removed for cleaning or for service.

W1021255

Rocker Arm and Push Rod

1. Remove the rocker arm bracket mounting bolts.

2. Detach the rocker arm assembly (1).

3. Remove the push rods (2).

(When reassembling)

• When putting the push rods (2) onto the tappets (3), check to see

if their ends are properly engaged with the dimples.

IMPORTANT

Q

• After installing the rocker arm, be sure to adjust the valve

clearance.

W1021437

Tightening torque

Nozzle holder assembly

49.0 to 68.6 N·m

5.0 to 7.0 kgf·m

36.2 to 50.6 ft-lbs

Overflow pipe assembly

retaining nut

19.6 to 24.5 N·m

2.0 to 2.5 kgf·m

14.5 to 18.1 ft-lbs

Glow plug

19.6 to 24.5 N·m

2.0 to 2.5 kgf·m

14.5 to 18.1 ft-lbs

(1) Glow Plug

(2) Nozzle Holder Assembly

(3) Copper Gasket

(4) Heat Seal

(5) Overflow Pipe Assembly

(1) Plus Screw Driver

(2) Nozzle Holder

(3) Copper Gasket

(4) Heat Seal

Tightening torque

Rocker arm bracket

mounting bolt

23.5 to 27.5 N·m

2.4 to 2.8 kgf·m

17.4 to 20.3 ft-lbs

(1) Rocker Arm Assembly

(2) Push Rod

(3) Tappet

KiSC issued 08, 2012 A