19

RISK OF FREEZING

IMPORTANT !

The engine should not be subjected to heavy loads when

ice starts to build up in the cooling system.

As the coolant starts to freeze, the water in the coolant

starts to crystallise and the percentage of ethylene glycol

in the coolant therefore rises. If freezing produces a

great increase in the amount of ice, circulation problems

could arise. There is no risk of damage by freezing if the

content of Scania antifreeze and corrosion inhibitor, or

an equivalent mixture of a similar product, is at least

35% by volume.

Minimal ice formation in the coolant sometimes causes

minor problems without any risk of damage. For example,

the auxiliary heater may not work for up to 1 hour after

the engine has been started.

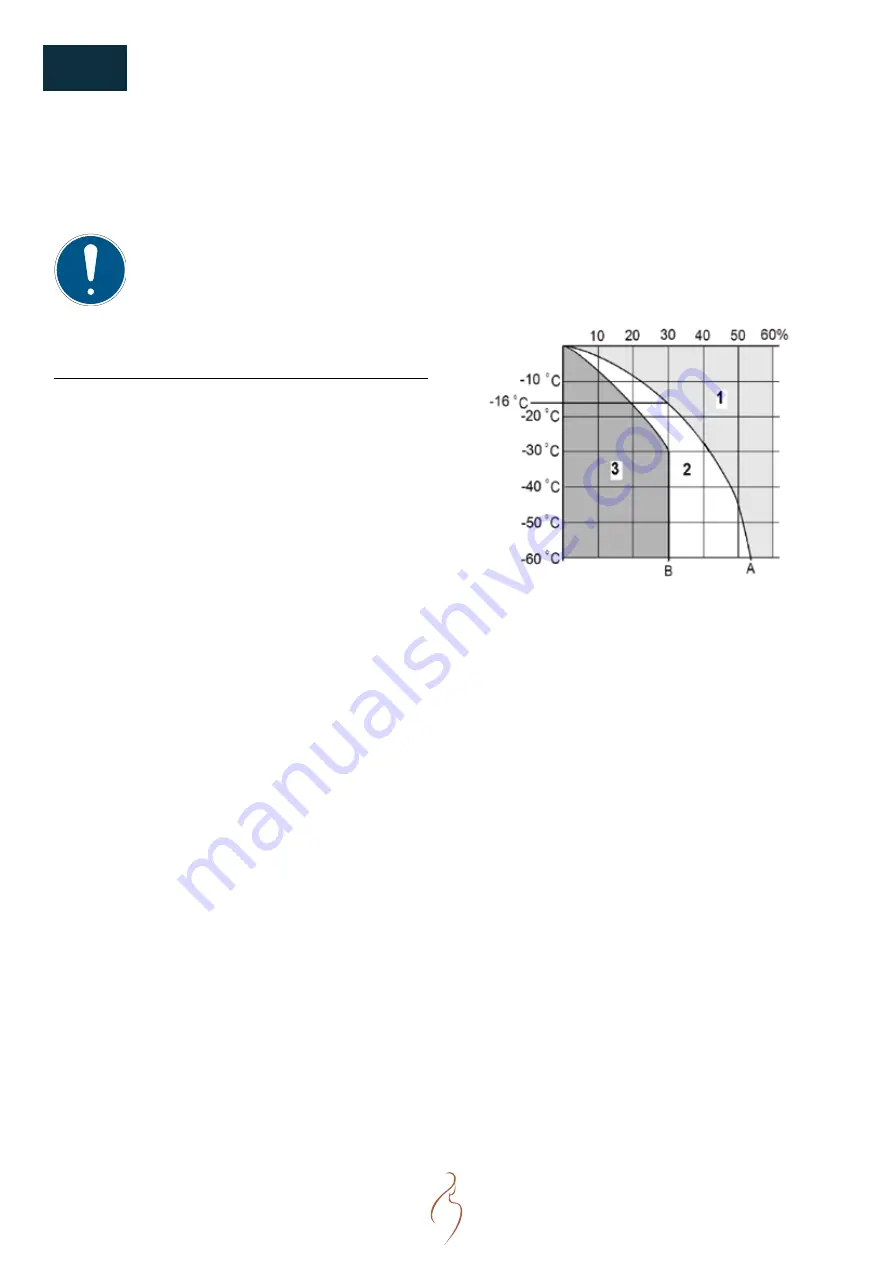

The chart depicts coolant properties at different percents

of antifreeze and corrosion inhibitor concentration by

volume.

Curve A: Ice formation starts (ice slush)

Curve B: Damage by freezing

Range 1: Safe range

Range 2: Malfunctions may occur (ice slush)

Range 3: There is risk of damage by freezing

The following example shows coolant properties with 30

percent by volume of antifreeze and corrosion inhibitor:

• Ice slush starts to form at -16°C (3°F).

• At -30°C (-22°F), there is a risk of cooling system mal-

function.

• There is no risk of damage by freezing with a minimum

antifreeze and corrosion inhibitor content of 35 percent

by volume.

Example:

If the temperature is -16 C (3°F), there is a risk of dam-

age by freezing if the percentage of antifreeze and cor-

rosion inhibitor is 20% by volume. At 30% antifreeze and

corrosion protection by volume the coolant will not con-

tain any ice.

HOT CLIMATES

In order to retain the corrosion protection and the higher

boiling point, it is essential to use coolant consisting of

water mixed with antifreeze and corrosion inhibitor (eth-

ylene glycol). This also applies in countries where the

temperature never drops below 0°C (32°C).

The coolant should always contain 35-55% by volume

of antifreeze and corrosion inhibitor so that the coolant

properties ensure that the coolant works correctly.

TOPPING UP

Coolant must only be topped up with pre-mixed cool-

ant. The pre-mixed coolant can either be concentrate

mixed with clean freshwater or pre-mixed coolant from

the factory. Use only pure fresh water that is free from

particles, sludge and other impurities.

S03

FLUIDS

Summary of Contents for N16.1000 CR3

Page 2: ......

Page 4: ......

Page 34: ...34 S05 COMPONENTS ENGINE VIEWS N16 CR3...

Page 35: ...35 NOTES...

Page 48: ...48 S06 INSTRUMENTATION SYSTEM LAYOUT INCLUDING OPTIONS...

Page 118: ......