38

S06

INSTRUMENTATION

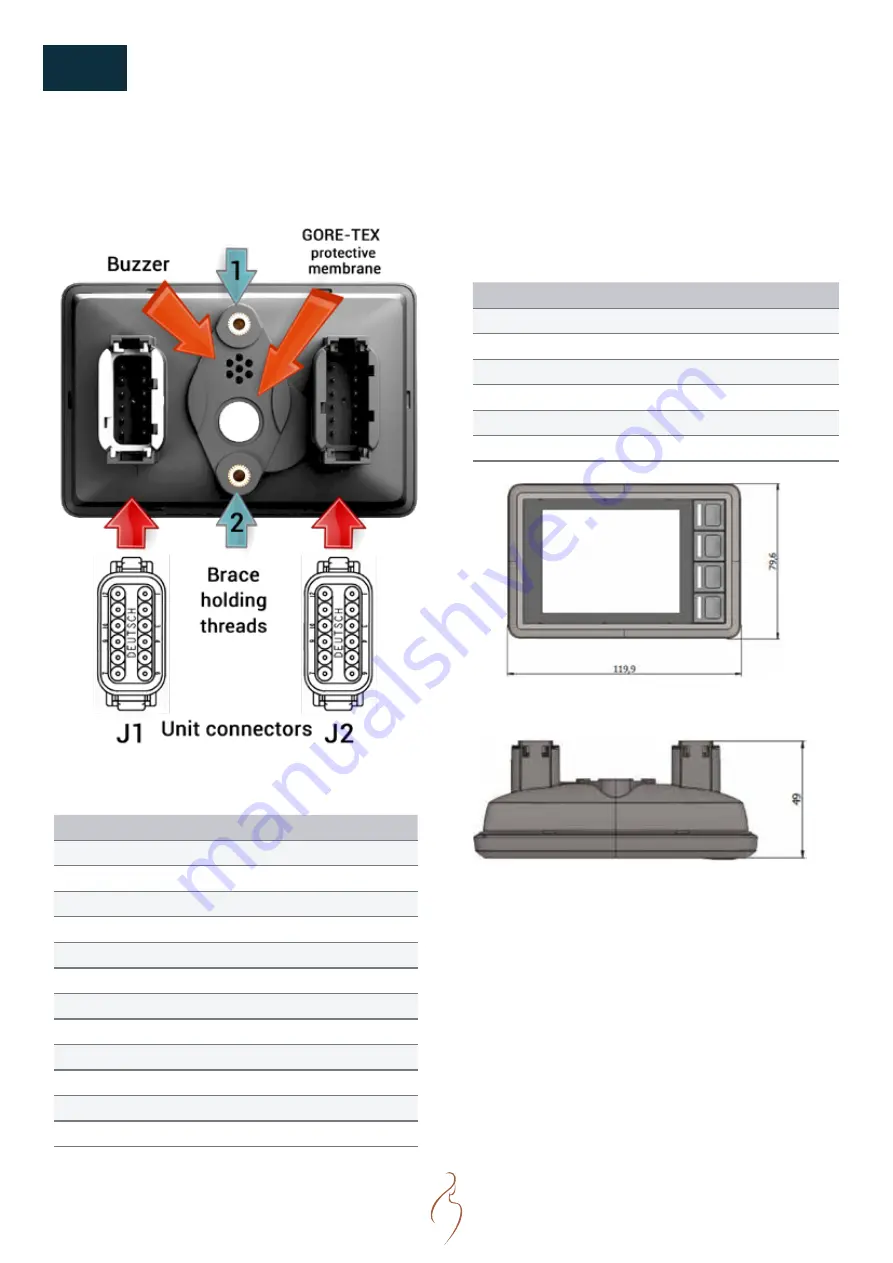

REAR SIDE

Connectors layout

Pin Function

Pin

Function

J1-1 Power 12/24V

J2-1

Configurable input -1

J1-2 GND

J2-2

Configurable input -2

J1-3 Switched power

J2-3

Configurable input -3

J1-4 Switched output 1

J2-4

Configurable input -4

J1-5 Switched output 2

J2-5 Analog GND

J1-6 CAN 1 Shield

J2-6 Analog input - 1

J1-7 CAN 1 +

J2-7 Analog input - 2

J1-8 CAN 1 -

J2-8 Analog input - 3

J1-9 USB GND

J2-9 Ethernet RD+

J1-10 USB Data -

J2-10 Ethernet RD-

J1-11 USB Data-

J2-11 Ethernet TD+

J1-12 USB Vbus

J2-12 Ethernet TD-

DIMENSIONS & WEIGHT

The rugged unit is made of thermoplastic polymer

compound (PBT), impact resistant and flame retarded.

Item

Description

Dimensions

119,9 (W) x 79,6 (H) x 49 (D), in mm

Weight

0,250 kg

Spacing threads

48,5 mm

Threads dimension M5

Threads depth

7,7 mm

Enclosure

PBT+ PC plastic

MOUNTING

The SI.3 supports two different mounting methods, a

RAM mount or a panel mount. These two mounting

methods are described below.

For both fastening methods, use the appropriate M5 x

0.8 button head screw of type MRT (Torx).

The recommended torque for the screws is of 1.5-2.0

Nm. Using fluid locker or locking washers (split ring,

toothed lock, etc.) is required for good securing. Ensure

that the M5 mounting screws are clean and dry before

mounting.

Summary of Contents for N16.1000 CR3

Page 2: ......

Page 4: ......

Page 34: ...34 S05 COMPONENTS ENGINE VIEWS N16 CR3...

Page 35: ...35 NOTES...

Page 48: ...48 S06 INSTRUMENTATION SYSTEM LAYOUT INCLUDING OPTIONS...

Page 118: ......