66

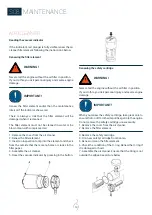

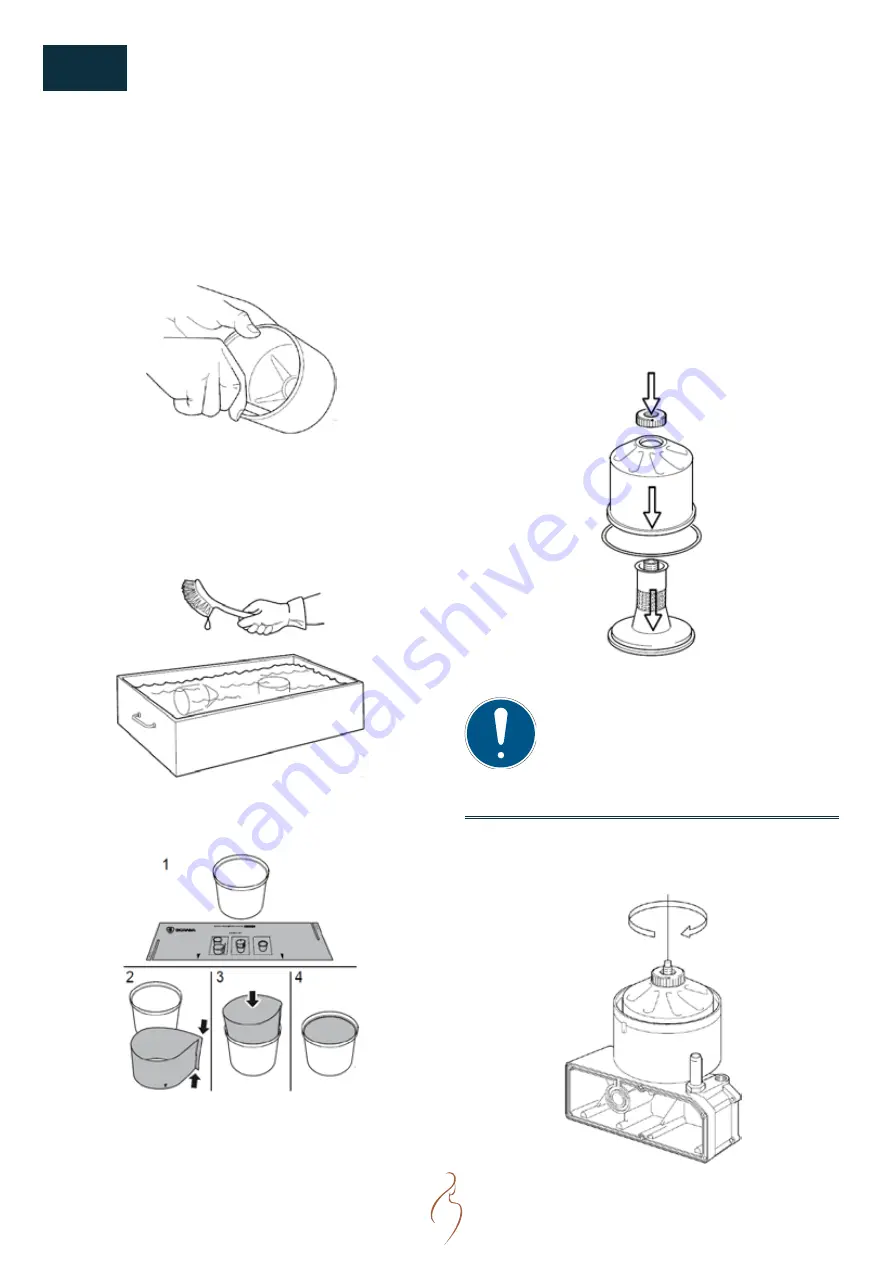

14. Remove the paper insert.

15. Scrape off any remaining dirt deposits from the

inside of the rotor cover. If the deposits on the paper are

thicker than 28 mm (1.1 in), the centrifugal oil cleaner

must be cleaned more often.

16. Wash the parts according to the applicable industrial

method.

17. Check the 2 nozzles on the rotor. Ensure that they are

not blocked or damaged. Renew any damaged nozzles.

18. Check that the bearings are undamaged. Renew

damaged bearings.

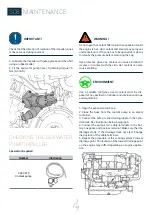

19. Fold and fit a new paper insert on the inside of the

rotor cover as illustrated below:

20. Fit the strainer onto the rotor.

21. Fit a new O-ring to the foot of the centrifugal oil

cleaner.

22. Refit the rotor cover. Ensure that the O-ring is not

outside the edges, but is in the groove.

23. Screw the rotor nut back on by hand.

24. Check that the shaft is not damaged or loose.

Contact a workshop with qualified personnel if the rotor

shaft needs to be renewed.

NOTE !

Take care not to damage the rotor shaft.

25. Refit the rotor and rotate it by hand to make sure it

rotates easily:

S08

MAINTENANCE

Summary of Contents for N16.1000 CR3

Page 2: ......

Page 4: ......

Page 34: ...34 S05 COMPONENTS ENGINE VIEWS N16 CR3...

Page 35: ...35 NOTES...

Page 48: ...48 S06 INSTRUMENTATION SYSTEM LAYOUT INCLUDING OPTIONS...

Page 118: ......