67

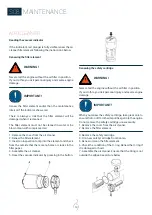

26. Fit a new O-ring in the cover.

27. Refit the cover and tighten the lock nut.Tightening

torque is of 20 Nm (15 lb-ft).

IMPORTANT !

To reduce the risk of oil leakage it is important to tighten

the cover to the correct tightening torque.

S08

MAINTENANCE

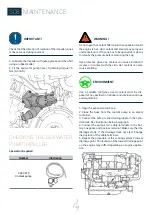

OPERATIONAL TESTING

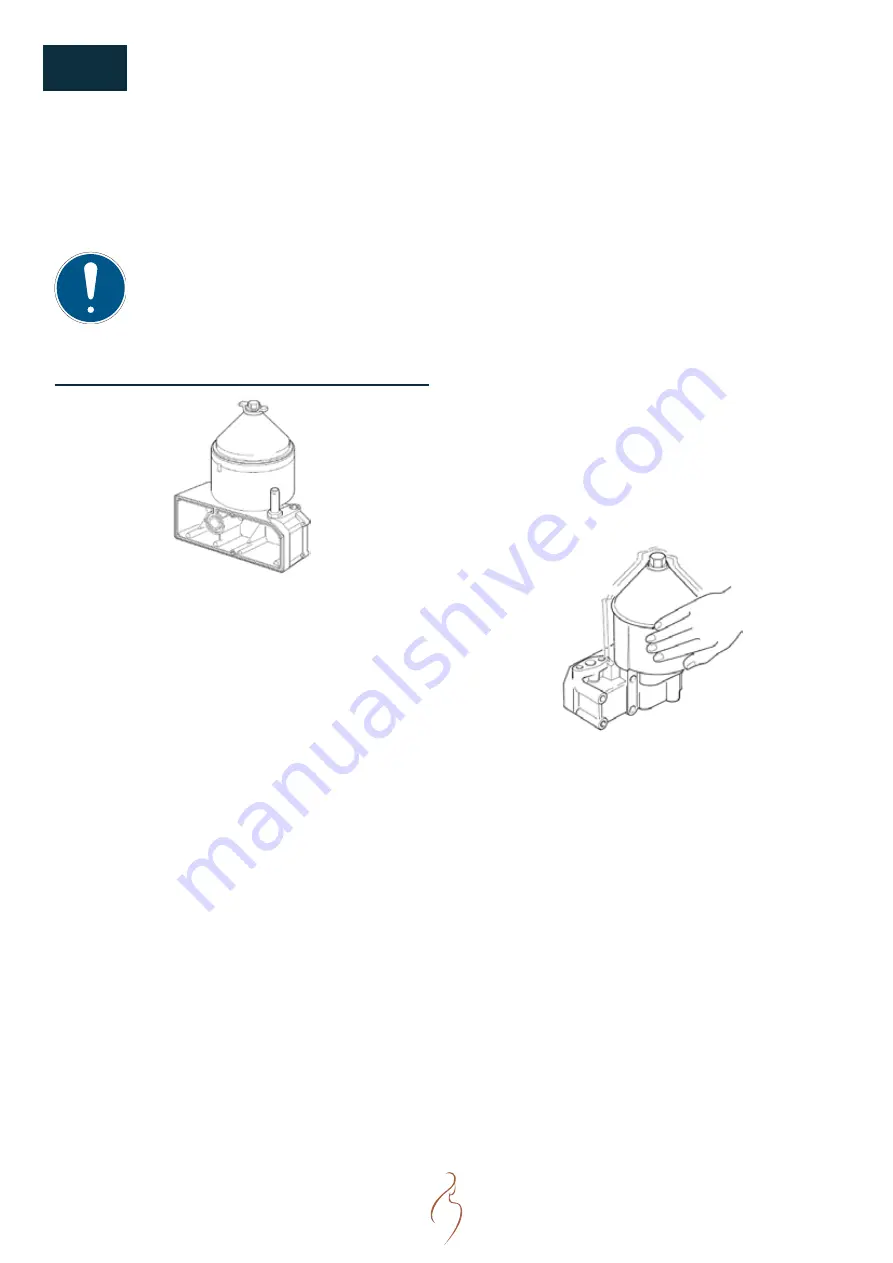

OF THE CENTRIFUGAL OIL

CLEANER

Operational testing need only be carried out if

it is suspected that the centrifugal oil cleaner is

malfunctioning. For example, if there are unusually few

deposits given the distance driven.

1. Run the engine until it reaches normal operating

temperature.

2. Stop the engine and listen for noise coming from the

rotor. It should continue rotating for a time, even when

the engine has stopped.

3. Use your hand to feel if the filter housing is vibrating.

4. If the filter housing is not vibrating, dismantle and

check the centrifugal oil cleaner.

Summary of Contents for N16.1000 CR3

Page 2: ......

Page 4: ......

Page 34: ...34 S05 COMPONENTS ENGINE VIEWS N16 CR3...

Page 35: ...35 NOTES...

Page 48: ...48 S06 INSTRUMENTATION SYSTEM LAYOUT INCLUDING OPTIONS...

Page 118: ......