85

4.

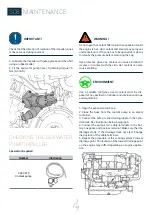

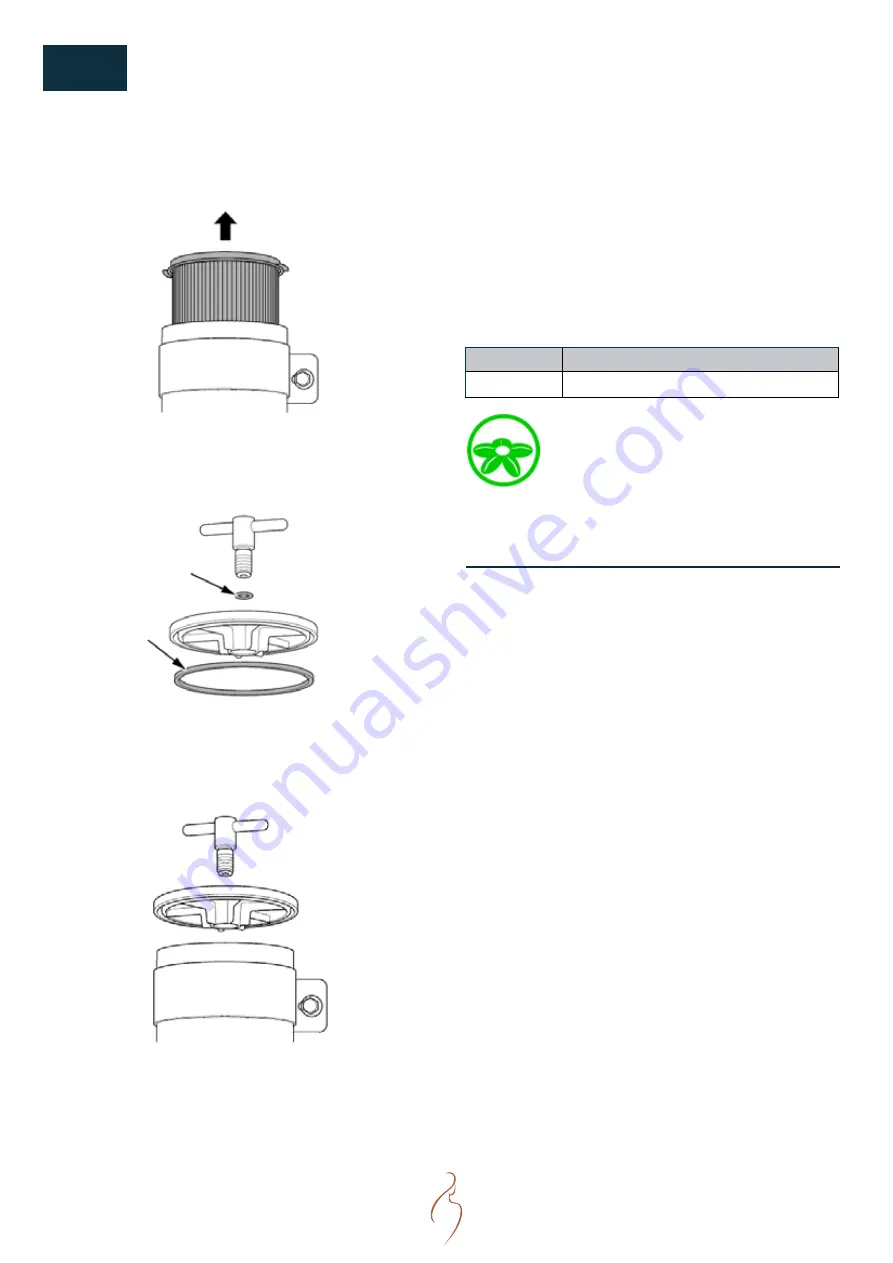

Remove the filter and fit the new filter.

5. Renew the O-rings in the cover.

6. Lubricate the O-rings with engine oil.

7.

Fill the filter housing with clean fuel.

8. Fit the cover. Tighten the cover screw by hand.

S08

MAINTENANCE

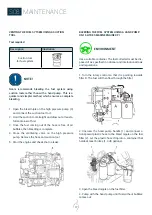

RENEWING THE COMMUTA-

TIVE FUEL FILTER, 16 LITRE

MARINE ENGINE WITH XPI

Tools required

Number

Description

2 002 537

Grease for O-ring

ENVIRONMENT

Use a suitable container. The fuel collected must be dis-

posed of as specified in national and international laws

and regulations.

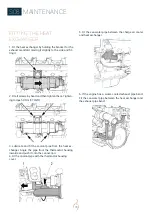

1. Start the engine. During operation, the rotary control

should point 90° towards the filter being used.

2. Turn the rotary control 90° to the right so that it

points towards filter B. The fuel then flows through the

filter.

3. Connect a clear plastic hose to the bleed nipple

sitting above filter A. Place the other end in a container

with a capacity of at least 3.8 litres (1 US gallon).

4. Open the bleed nipple on side A. The remaining pres-

sure is released.

5. Clean the exterior of the filter with a cloth.

6. Unscrew the filter.

7. Apply O-ring grease, part number 2 002 537, to the

gasket on the new filter.

8. Screw the filter into place by hand until it makes con

-

tact. Screw a further half turn by hand.

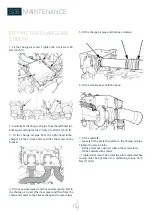

9. Turn the rotary control 90° to the left so that the

rotary control points straight up. Both filters now run

simultaneously.

10. When fuel without air bubbles comes out, close the

bleed nipple. Tightening torque 9 Nm. Because the en-

gine is running, a lot of fuel will come through the hose.

11. Turn the rotary control 90° to the left so that the

pointer is pointing towards filter A. Filter B can then be

renewed in the same way as filter A.

See related illustration on next page:

Summary of Contents for N16.1000 CR3

Page 2: ......

Page 4: ......

Page 34: ...34 S05 COMPONENTS ENGINE VIEWS N16 CR3...

Page 35: ...35 NOTES...

Page 48: ...48 S06 INSTRUMENTATION SYSTEM LAYOUT INCLUDING OPTIONS...

Page 118: ......