91

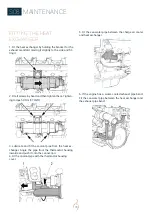

1. Clean the rocker covers and the area around them.

2. Remove the rocker covers.

3. In order to rotate the flywheel, use a turning tool

compatible with the installation of the engine, i.e.

whether access is from above or from underneath.

Use any specified special tool or the equivalent from

another supplier.

4. Start adjusting one cylinder according to the table.

Rotate the flywheel until the correct engraving can be

read on the flywheel. It may be necessary to rotate it

more than 1 revolution.

Rotate the flywheel in the rotational direction of the

engine, which is clockwise viewed from the front of

the engine and anticlockwise viewed from the back

of the engine.

During a valve transition, the exhaust valve (the long

arm) is closing at the same time as the intake valve

is opening.

The UP TDC engraving on the flywheel is now visible

in the window furthest up on the flywheel. The DOWN

TDC engraving is visible in the lower window.

5. Read the table on the previous page to see which

valve to adjust.

6. Stick the feeler gauge under the pressure pad of the

rocker arm and check the valve clearance.

7. If necessary, adjust the valve clearance by

a) loosening the lock nut on the end of the rocker

arm

b) adjusting the valve clearance with the adjusting

screw

c) tightening the lock nut.

8. Mark the rocker arm with the felt-tip pen and then

continue with the next cylinder according to the table.

S08

MAINTENANCE

Legend:

1. Adjusting screw

2. Lock nut

3. Rocker arm

4. Valve bridge

5. Feeler gauge

Summary of Contents for N16.1000 CR3

Page 2: ......

Page 4: ......

Page 34: ...34 S05 COMPONENTS ENGINE VIEWS N16 CR3...

Page 35: ...35 NOTES...

Page 48: ...48 S06 INSTRUMENTATION SYSTEM LAYOUT INCLUDING OPTIONS...

Page 118: ......