66

COOLANT

WATER & ANTI-FREEZE:

Please refer to the Fluids section for complete information.

WATER BOILER:

A water boiler can be connected to the engine coolant

circuit. If the boiler is located above the engine, an

additional recovery tank must be installed above the

boiler.

Ducts to the boiler must be in accordance with high

temperature and high pressure. Do not use flexible hoses

supplied from a general hardware store.

A specific boiler kit is available from Nanni Industries.

Please contact your nearest Nanni representative for

more information.

The amount of coolant must be adapted depending

the model of water boiler to completely fill the coolant

system.

COOLANT EXPANSION:

When the engine is running, the internal temperature is

high ; as a result, the coolant liquid expands its volume.

The heat exchanger is designed to accomodate this

normal and physical expansion.

Make sure not to overfill the heat exchanger when filling

with coolant.

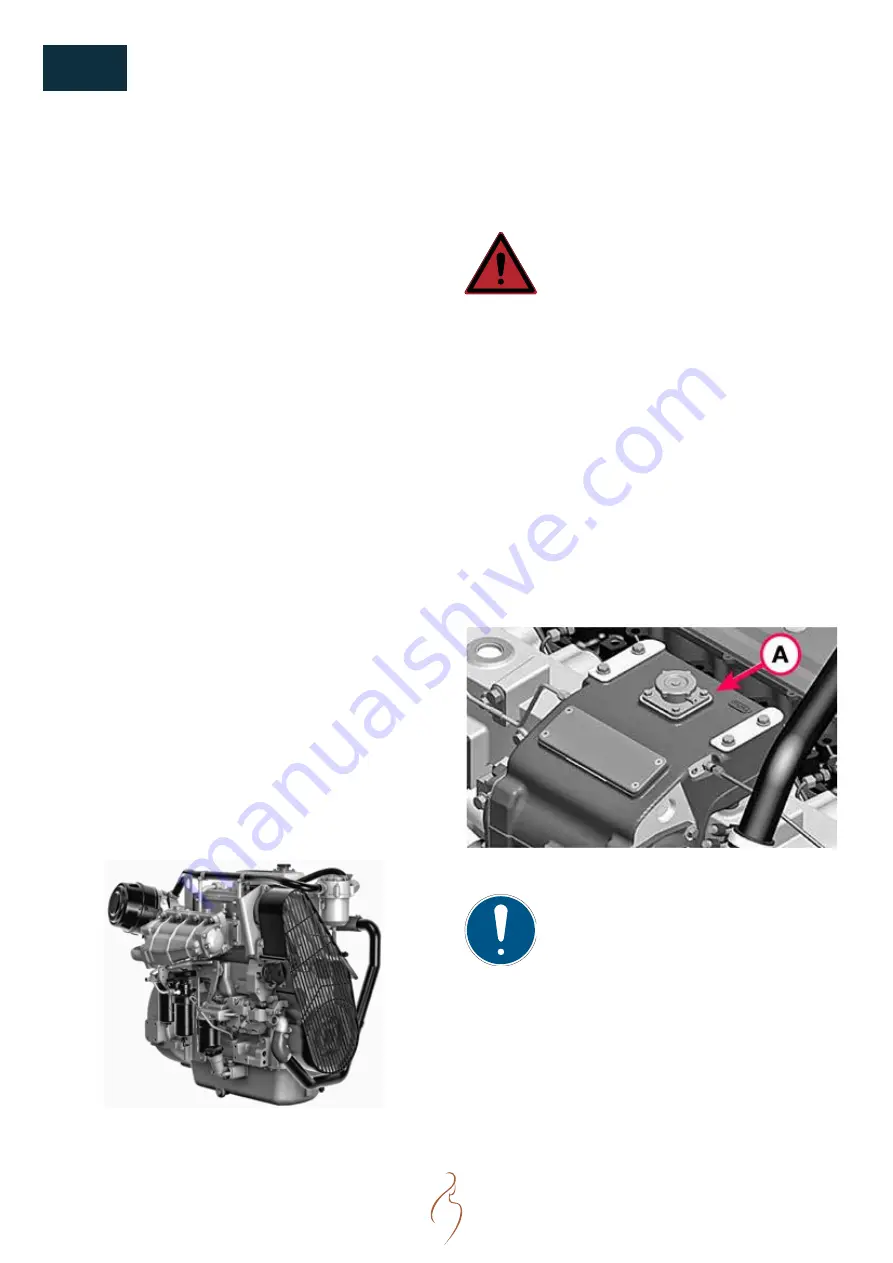

COOLANT LEVEL

DANGER !

Never open the coolant filling cap or any plug of the

cooling system when the engine is operating or still

warm. Steam or hot fluid can spray out. Prevent potential

injuries !

Check the coolant level before starting the engine.

1. Stop the engine and remove the key from the panel.

2.

Unscrew the filler cap (

A

) on the exchanger tank on

picture below.

3. You may top-up with clean water only, if amount to

fill is very remote. Use glycol mix if tank is almost

empty.

4.

Stop filling when level is at bottom lip of the cap filler.

NOTE !

This Max level in the tank is representing the effective

level of coolant only when the engine is cold.

S08

MAINTENANCE

Summary of Contents for N5.150

Page 2: ......

Page 4: ......

Page 40: ...40 NOTES...

Page 77: ...77 S08 MAINTENANCE INSTRUMENTS PANEL...

Page 103: ......