73

S08

MAINTENANCE

RAW WATER SYSTEM - CLEANING

RAW WATER SYSTEM CLEANING:

The raw water system must be cleaned to remove the

building up of deposits and salt crystals as soon as

detected or suspected.

1. Stop the engine and close the sea cock valve.

2. Disconnect the hose on the outlet side of the raw

water filter.

3.

Place the freed hose end in a container filled with

fresh water. Ensure that the tank is large enough as

the raw water pump must never run without water.

Keep enough water on hand to add up constantly.

4. Check that no one is in the vincinity of the engine,

the propeller and the exhaust outlet. Put the lever in

neutral and start the engine.

5. Let the engine to run for a few minutes at idle. Add up

fresh water in the container before container is being

emptied.

6. Stop the engine.

7. At this stage, the raw circuit is alleged to be cleaned

up. If deposits and salt crystals are still present,

consult your Nanni representative. Do not add up

cleaners additives like caustic soda, as aluminium

parts are prone to fast corrosion if harshly cleaned.

8. Clearly identify all closed valves with labels: on

wheelhouse dashboard, on valves.

RISK OF ICING CONDITIONS. PROTECTION AGAINST FROST:

1. Start process after point 8 of previous paragraph

is done. Empty the remaining fresh water left in the

container.

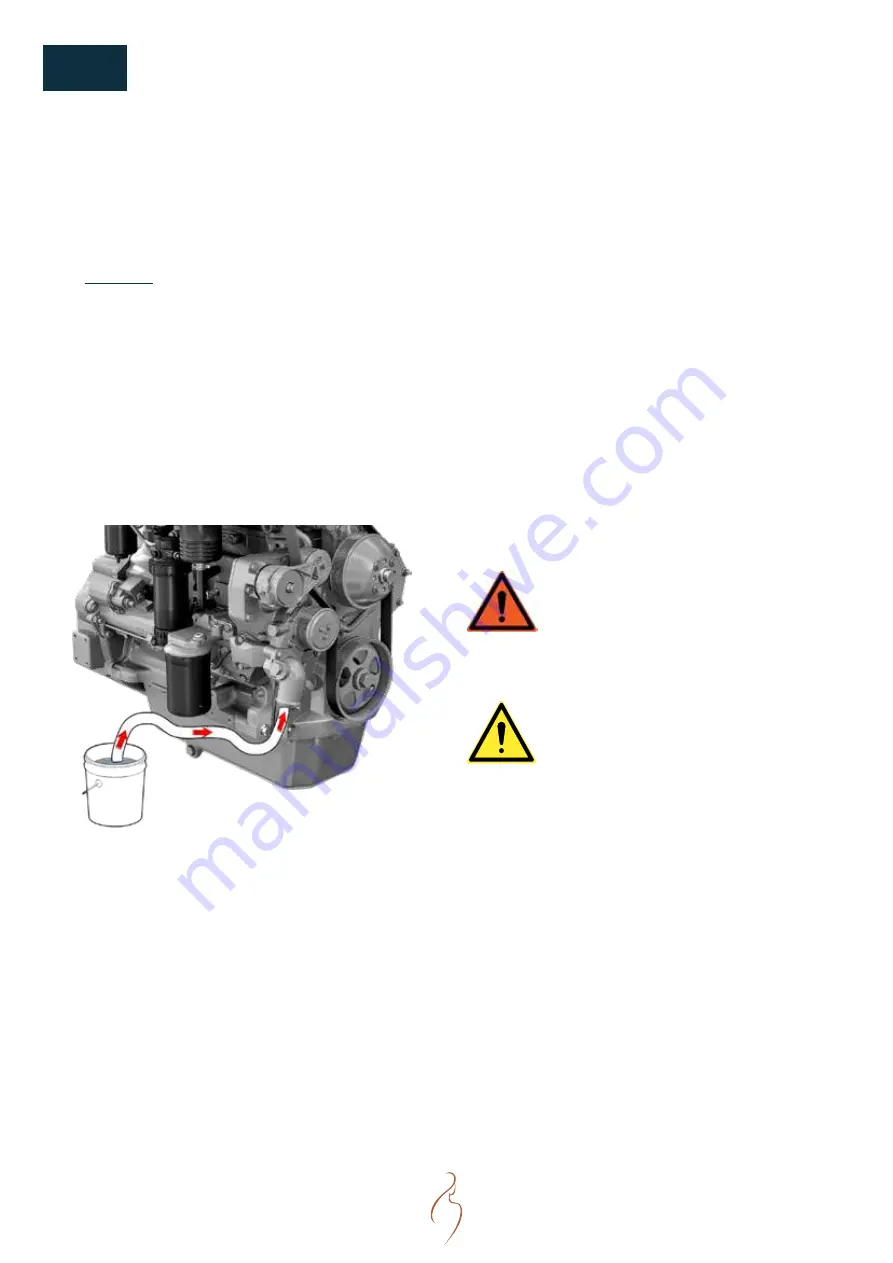

2. Fill the container with engine coolant mix (50% clean

water, 50% anti-freeze).

3. Start the engine and let it run at idle. Add enough

coolant to fill the raw water system with coolant.

4. Stop the engine before the container is empty.

5. Reconnect the hose.

6. Clearly identify all closed valves with labels: on

wheelhouse dashboard, on valves.

7.

Drain the coolant mix and refill the raw water circuit

when safe weather conditions are resuming.

WARNING !

Check for leaks before the next engine start.

CAUTION !

When preparing the engine for long term storage, if the

engine is likely to be subject to frost, drain and flush

away all water remaining in the raw filter circuit.

Summary of Contents for N5.150

Page 2: ......

Page 4: ......

Page 40: ...40 NOTES...

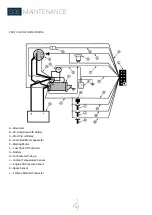

Page 77: ...77 S08 MAINTENANCE INSTRUMENTS PANEL...

Page 103: ......