68

S08

MAINTENANCE

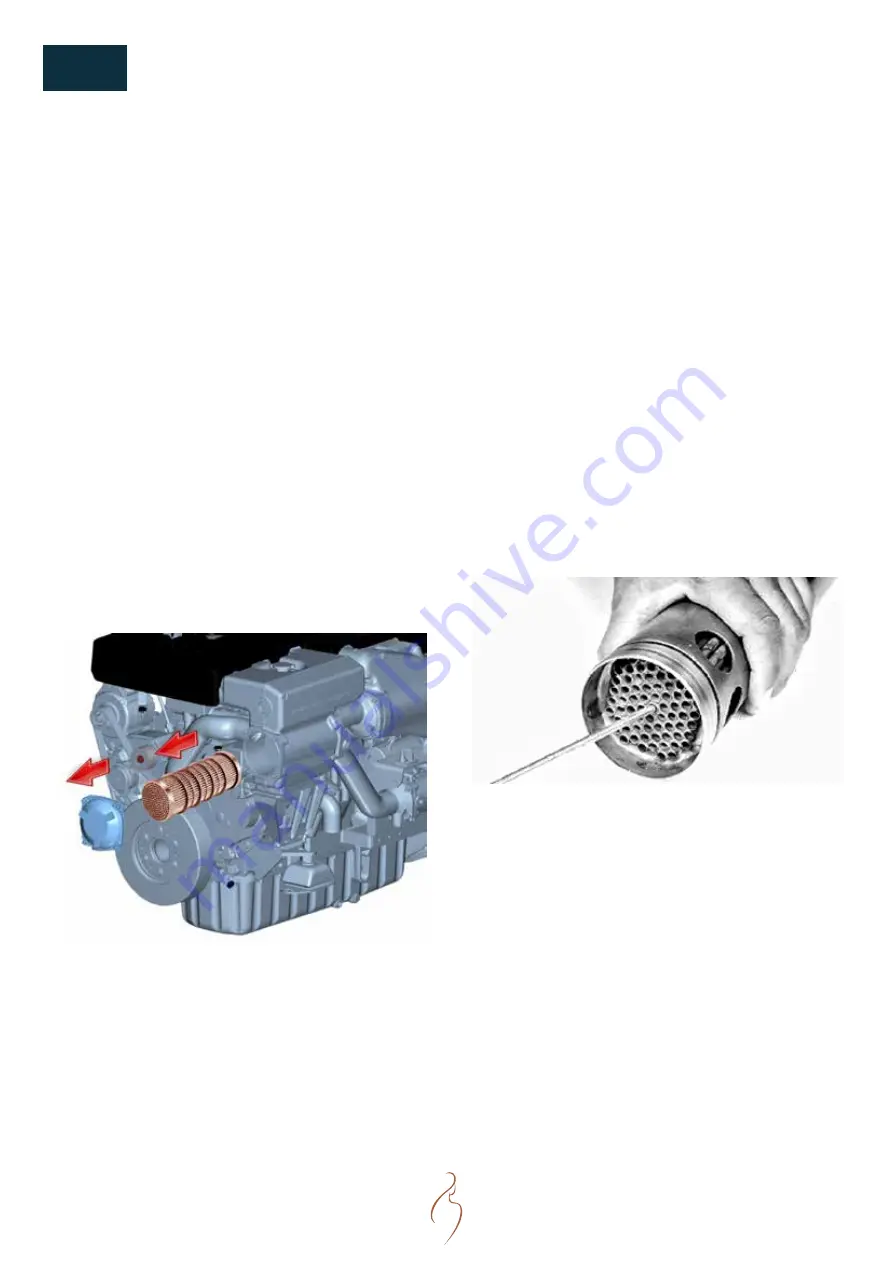

HEAT EXCHANGER SERVICE

HEAT EXCHANGER INSPECTION :

1. Close sea cocks and drain the sea water system.

2. Open drain valve on cylinder block and drain engine

coolant into a clean container. Close drain valve.

3. Loosen hose clamps and disconnect sea water tube.

4. Remove cap screws and remove rear end cap. Identify

end cap so it can be installed in the same position as

removed.

5. Remove socket head cap screws.

6. Remove cap screws and remove front end cap. Identify

end cap so it can be installed in the same position as

removed.

7. Thoroughly inspect condition of end cap sealing O-

rings. Sealing O-rings may be reused if not excessively

worn or damaged during disassembly. Replace sealing

rings as necessary.

8. Remove socket head cap screws.

9. Remove heat exchanger core tube stack through rear

side of housing.

10. Remove remaining end cap from water manifold/

heat exchanger housing. Remove end cap from heat

exchanger core.

11.Thoroughly clean all buildup from both end caps

and inspect zinc plug in each. Replace plugs as needed.

12. Use a brass rod to clean out any buildup in each

heat exchanger tube. Run the rod the entire length of

each tube to push debris out. Flush the heat exchanger

tubes with clean water, making sure all tubes are

cleared of debris.

If you suspect that your heat exchanger core tube stack

is defective, have your authorized Nanni representative

to handle this task. Remove and thoroughly clean with

water the manifold/heat exchanger housing as needed.

Inspect end cap O-rings which may be reused if not

worn nor flattened. Lubricate front and rear end cap

O-rings with clean multi-purpose grease. Thighten cap

screws to 49 Nm (36 lb-ft).

Summary of Contents for N9.330 CR2

Page 2: ......

Page 4: ......

Page 39: ...39 S06 COMPONENTS ENGINE VIEWS N9 CR2 SERIES 1 6 12 19 10 3 13 8 16 2 14 5 18...

Page 40: ...40 ENGINE VIEWS N9 CR2 SERIES S06 COMPONENTS 5 21 12 20...

Page 52: ...52 NOTES...

Page 106: ......

Page 107: ......