61

S 07

MAINTENANCE

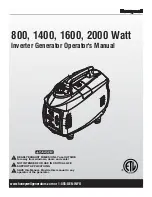

the fuel filter a few turns. Open the fuel drain valve

(2).

Engine equipped with an electric pump (optional).

• Turn the key to the ON position and feed fuel

through the pump for 10 to 15 seconds.

Engine equipped with a mechanical pump (standard)

•

Turn the stop lever to the STOP position and run

the engine with the starter motor for 10 to 15 sec-

onds.

•

Close the air bleed valve properly after bleeding

the air.

• Tighten the cap (1) when the bubbles no longer

rise.

•

Close the bleed valve (2) on top of the fuel injec

-

tion pump.

NOTE!

Always keep the air bleed valve on the injection pump

closed unless you are releasing air. Otherwise, it may

cause the engine to stop.

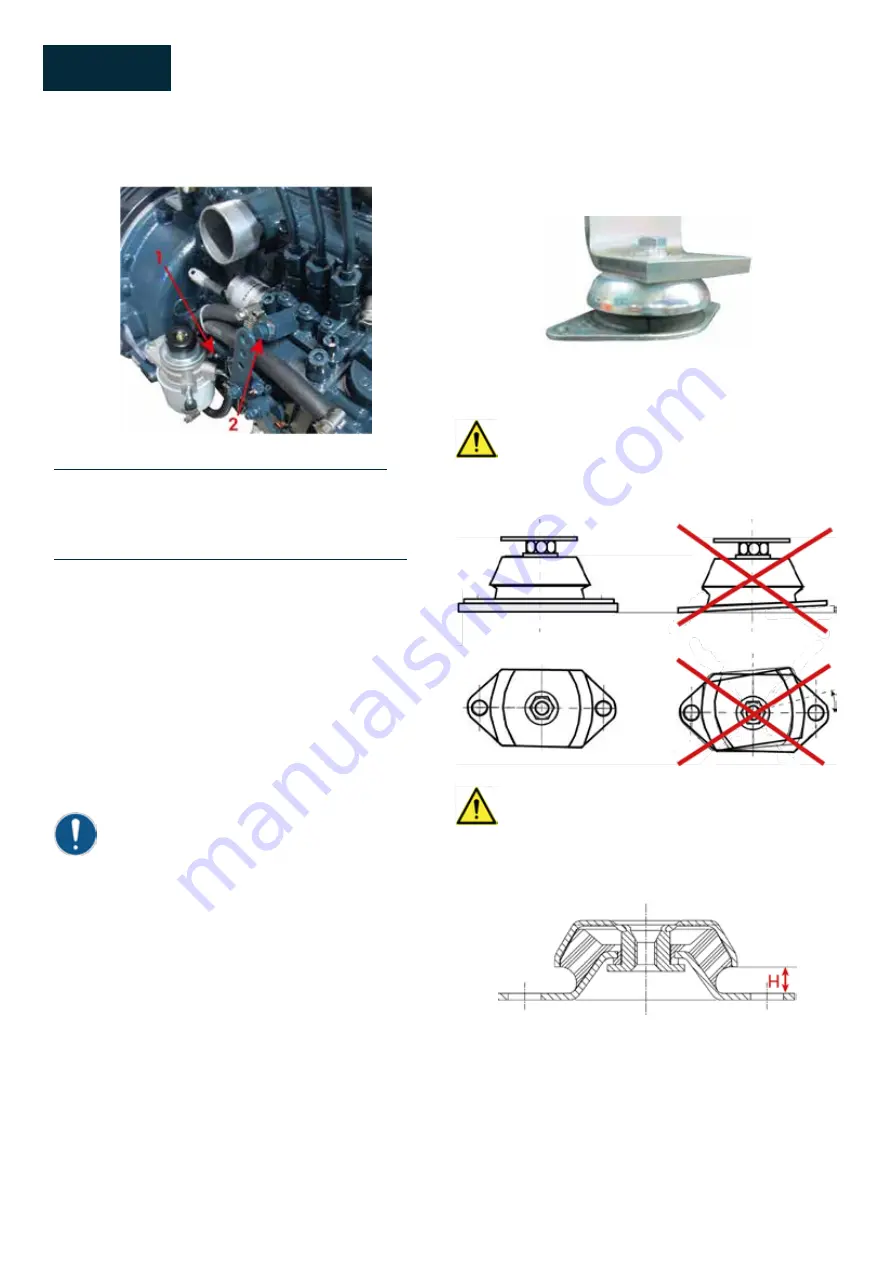

FLEXIBLE ENGINE MOUNTS

On new or outdated generators, make sure that the front

and rear flexible supports are properly adjusted.

Check that the four flexible brackets are correctly posi

-

tioned, then attach them to the frame.

CAUTION!

Twisting or straining of the rubber mounts is not accept-

able.

CAUTION!

The flexible support must be replaced every 2 years.

Observe the minimum value H (2 mm - 0.08 in.); if the

value is lower, replace the motor support.

Summary of Contents for Q1100 Series

Page 1: ...NANNI GENERATOR SET USER MANUAL DGBXXT090048 Q1100 Series...

Page 2: ......

Page 4: ...4 Q00 TRACKED CHANGES...

Page 8: ...8 S00 SUMMARY...

Page 32: ...32 S03 FLUIDS...

Page 38: ...38 S05 COMPOSANTS...

Page 40: ...40 S05 COMPOSANTS VIEW N 1 OF THE GENERATOR SET...

Page 41: ...41 S05 COMPOSANTS VIEW N 2 OF THE GENERATOR SET...

Page 52: ...52 S 07 MAINTENANCE Battery voltage 72 Battery specific gravity 72...

Page 53: ...53 S 07 MAINTENANCE...

Page 74: ...74 S 07 MAINTENANCE...

Page 76: ...76 S08 AL TERNATOR...

Page 88: ......

Page 96: ...96 S11 TROUBLE SHOOTING...

Page 97: ......

Page 98: ......