15

S02

SAFETY

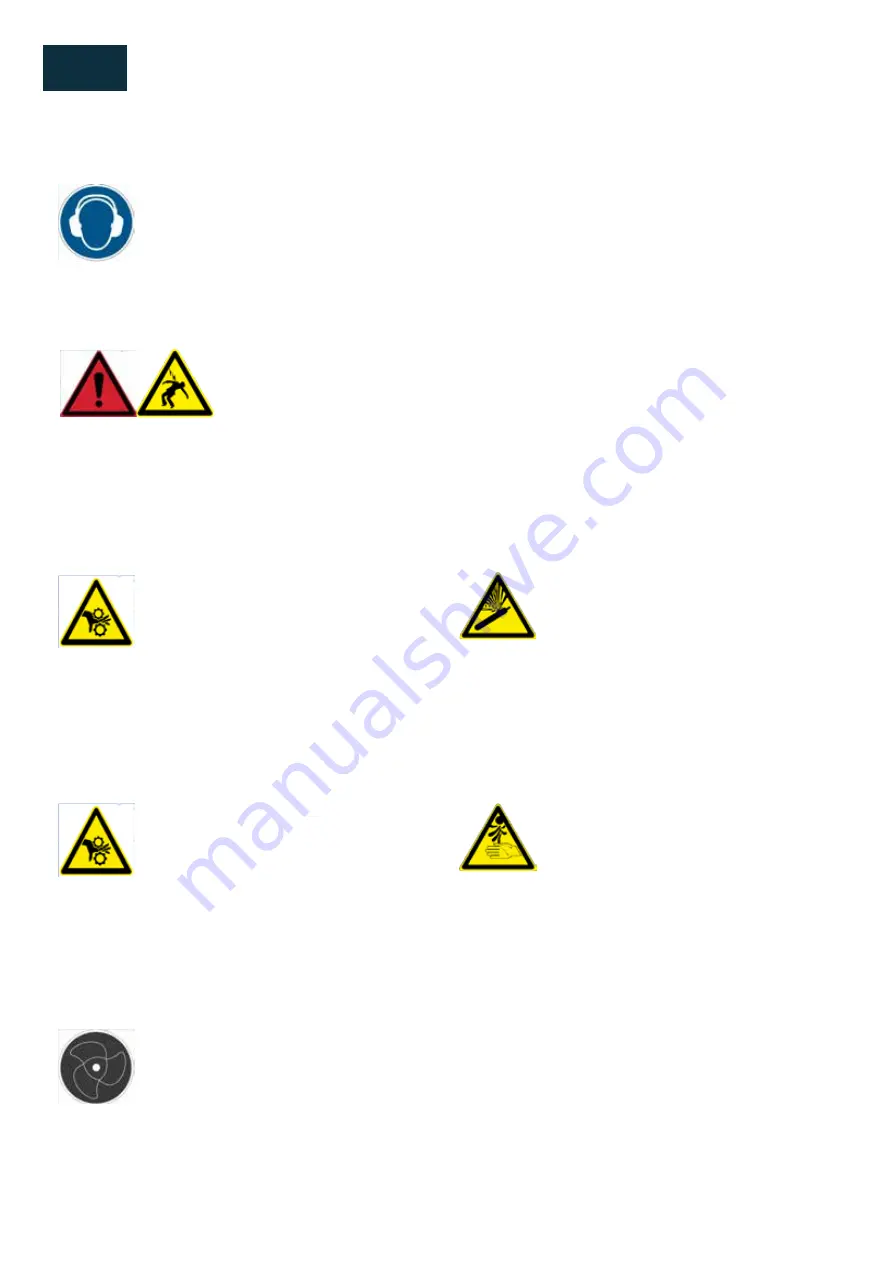

NOISE PROTECTION

Prolonged exposure to loud noise can

cause impairment or loss of hearing. Wear

a suitable hearing protective device such

as earmuffs or earplugs to protect against

objectionable or uncomfortable loud

noises

GENSET OUTPUT GENERATED POWER

Genset will deliver a sizeable amount of electrical power

which can be lethal if not handled properly. Thus, any

service, connection or repair on the alternator can only

done by a certified marine electrician

GUARDS REQUIREMENTS

Rotating cooling system fans, belts,

pulleys, and drives can cause serious

injury. Keep all guards in place at all times

during the engine operation. Wear close-

fitting clothes.

Stop the engine and be sure that fans, belts, pulleys,

and drives are stopped before making adjustments,

connections, or cleaning near fans and their drive

components.

STAYING CLEAR OF ROTATING DRIVE LINES

Entanglement in rotating driveline can

cause serious injury or death. Keep all

shields in place at all times. Make sure

rotating shields turn freely

Wear close-fitting clothing. Stop the engine and be sure

that all rotating parts and drive lines are stopped before

making adjustments, connections, or performing any

type of service on engine or driven equipment.

PAINT REMOVAL BEFORE HEATING

Avoid potentially toxic fumes and dust.

Hazardous fumes can be generated when

paint is heated by welding, soldering, or in

using a torch.

Paint removal :

•

Remove paint a minimum of 100 mm (4 in.) from

area to be affected by heating. If paint cannot be

removed, wear an approved respirator mask before

heating or welding.

•

If you sand or grind paint, avoid breathing the dust.

Wear an approved respirator.

•

If you use solvent or paint stripper, remove stripper

with soap and water before welding. Remove solvent

or paint stripper containers and other flammable

material from area.

•

Allow fumes to disperse at least 15 minutes before

welding or heating.

• Do not use a chlorinated solvent in areas where

welding will take place.

•

Do all work in an area that is well ventilated to carry

toxic fumes and dust away.

•

Dispose of paint and solvents properly.

HIGH - PRESSURE FUEL SYSTEM OPENING

RISK

High-pressure fluid remaining in fuel lines

can cause serious injury. Do not disconnect

or attempt repair of fuel lines, sensors,

or any other components between the

high-pressure fuel pump and nozzles on

engines with High Pressure Common Rail

(HPCR) fuel system.

Only technicians familiar with this type of system can

perform repairs. Consult your engine representative.

AVOID HIGH - PRESSURE FLUIDS

Inspect hydraulic hoses periodically – at

least once per year – for leakage, kinking,

cuts, cracks, abrasion, blisters, corrosion,

exposed wire braid or any other signs

of wear or damage. Replace worn or

damaged hose assemblies immediately

with approved replacement parts.

Escaping fluid under pressure can penetrate the skin

causing serious injury. Avoid the hazard by relieving

pressure before disconnecting hydraulic or other lines.

Tighten all connections before applying pressure.

Search for leaks with a piece of cardboard.

Summary of Contents for Q1500 Series

Page 1: ...NANNI GENERATOR SET USER MANUAL DGBXXT090049 Q1500 Series...

Page 2: ......

Page 4: ...4 Q00 TRACKED CHANGES...

Page 8: ...8 S00 SUMMARY...

Page 32: ...32 S03 FLUIDS...

Page 38: ...30 S05 COMPOSANTS...

Page 40: ...32 S05 COMPOSANTS VIEW N 1 OF THE GENERATOR SET...

Page 41: ...33 S05 COMPOSANTS VIEW N 2 OF THE GENERATOR SET...

Page 52: ...52 S 07 MAINTENANCE Battery voltage 72 Battery specific gravity 72...

Page 53: ...53 S 07 MAINTENANCE...

Page 74: ...74 S 07 MAINTENANCE...

Page 76: ...76 S08 AL TERNATOR...

Page 88: ......

Page 96: ...96 S11 TROUBLE SHOOTING...

Page 97: ......

Page 98: ......